Energy-saving compound concrete self thermal insulation building block

A technology of self-insulating blocks and concrete, which is applied in the direction of building materials, can solve the problems that it is difficult to achieve 65% energy saving, the effect of block thermal resistance is limited, and increase the amount of materials, so as to achieve fast construction speed, good thermal insulation performance, and reduce The effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

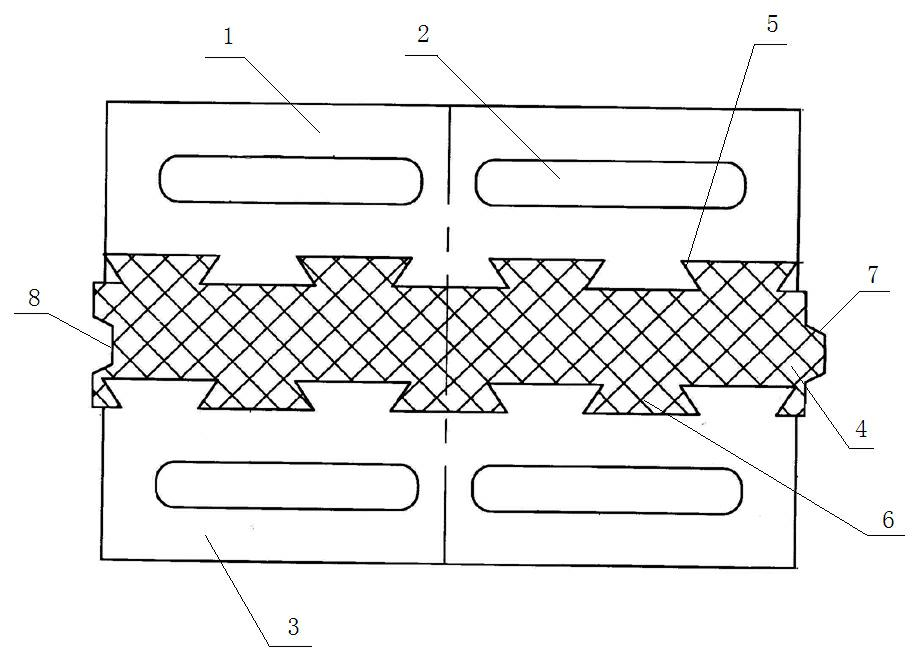

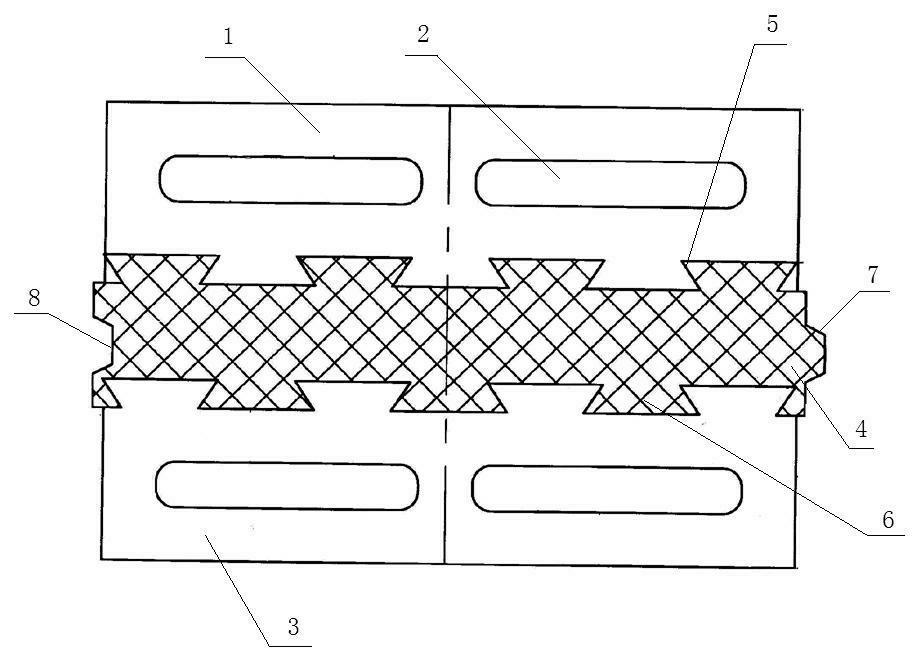

[0017] Such as figure 1 As shown, the block includes a left half block 1, a right half block 3 and an insulating block 4, a dovetail groove 5 is set on the inner side of the left half block 1 and the right half block 3, and a The dovetails 6 matching the dovetail grooves 5 are respectively arranged on both sides, and the insulation block 4 is located in the middle, and the left half block 1 and the right half block 3 are compounded into a three-in-one block through the dovetail grooves 5 and 6.

[0018] Wherein, protruding rafters 7 and grooves 8 are respectively arranged on the left and right sides of the insulation block 4 .

[0019] Wherein, the oblong hole 2 is set in the left half block 1 and the right half block 3 .

[0020] Among them, the size of the block is 390mm×240mm×190mm, the size of the EPS or XPB polystyrene insulation block is 390mm×80mm×190mm, the insulation block is located in the center of the block, and the left and right half of the block are symmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com