Reverse immersion method normal pressure hot-smouldering steel slag and waste heat recovery system and method

A technology of waste heat recovery system and waste heat recovery device, which is applied in the steam generation method using heat carrier and the improvement of process efficiency, etc. It can solve the problems of uneven slag effect, difficulty in collection and utilization, and high temperature of steel slag, so as to eliminate the hidden danger of explosion , The effect of reducing the amount of flue gas and increasing the heat recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

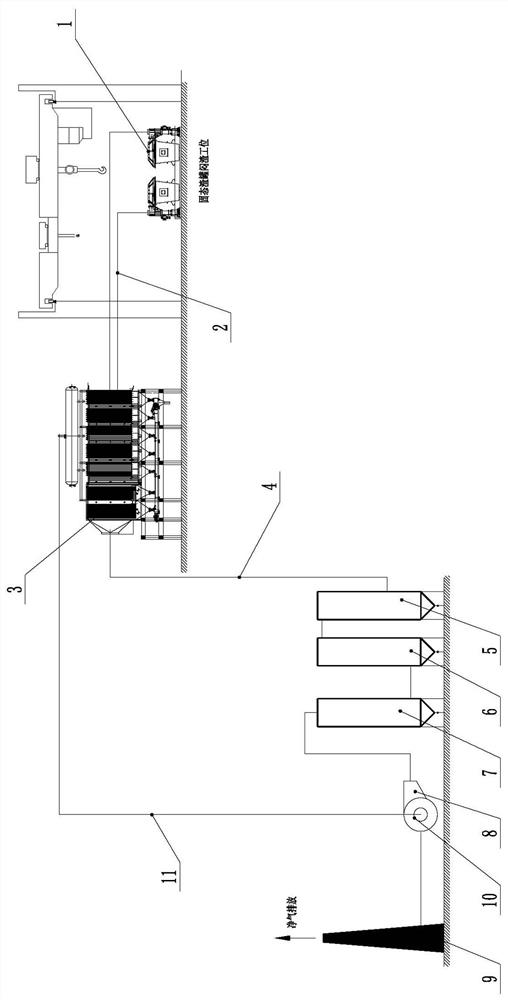

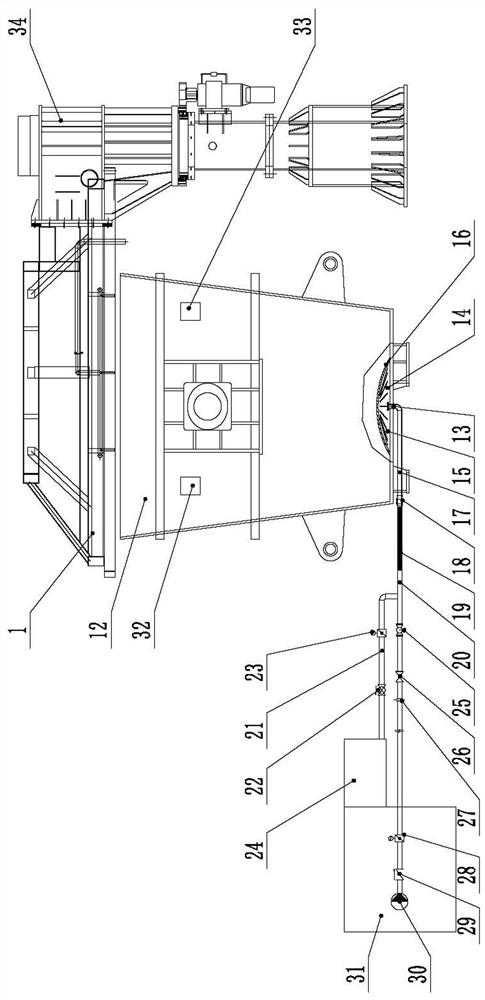

[0049] Such as Figure 1~Figure 2As shown, a reverse immersion method atmospheric pressure hot stuffy steel slag and waste heat recovery system, which includes a stuffy slag device and a waste heat recovery device connected to the stuffy slag device; the stuffy slag device includes a solid slag tank, a connected solid slag The water supply and drainage device at the bottom of the tank and the water-cooled dust collection hood 1 arranged above the solid slag tank; the waste heat recovery device includes a waste heat boiler 3 connected to the water-cooled dust collection hood 1 through a water-cooled flue 2, and the waste heat boiler 3 The low-temperature flue gas pipeline 4 communicates with the spray tower 5, the dehydrator 6, the wet electronic dust removal tower 7, the dust removal fan 8 and the clean gas discharge tower 9, which are connected in sequence. The dust removal fan 8 is driven by a steam turbine 10, and the waste heat The saturated steam pipe 11 of the boiler 3 i...

Embodiment 2

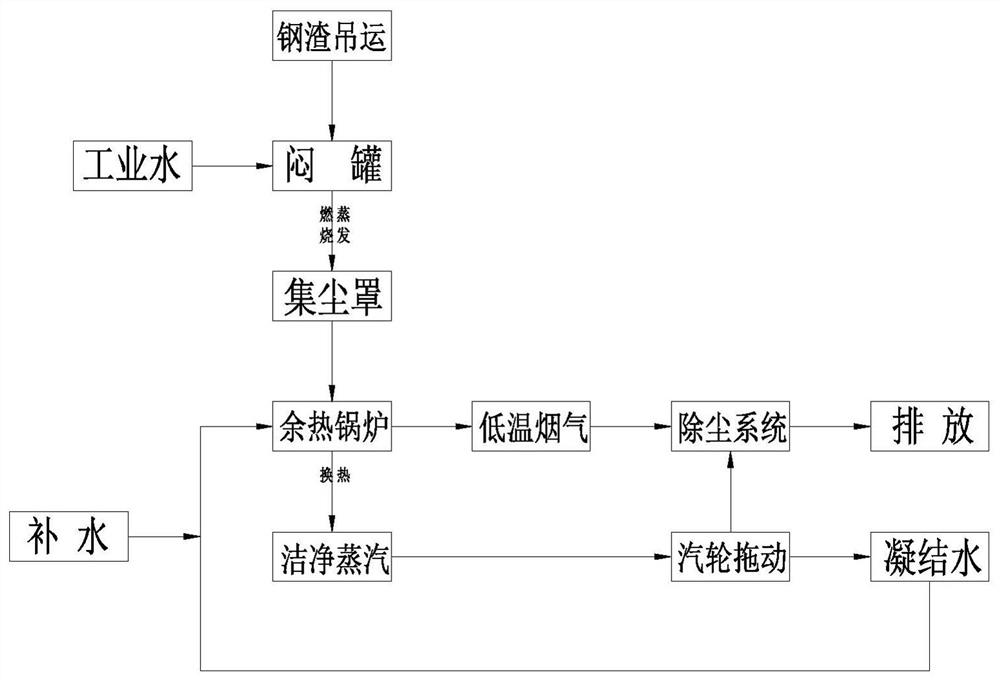

[0056] Such as image 3 As shown, utilize the system described in embodiment 1 to carry out the method for reverse immersion method normal pressure hot stuffy steel slag and waste heat recovery, it comprises the steps:

[0057] (a) Put the crushed steel slag above 800℃ into the solid slag tank.

[0058] Under the premise that the molten steel slag forms a solid state, the higher the temperature, the better the recovery effect of the slag and waste heat; the bottom of the solid slag tank is equipped with an anti-blocking and leak-proof water supply and drainage device, which can ensure that the cooling water enters and discharges the solid slag tank. Not to be blocked.

[0059] (b) Place the solid slag tank on the work station with a crane, connect the water supply pipe with a quick connector hose, and use the water supply and drainage device to supply water from the bottom of the solid slag tank to the inside of the solid slag tank according to the water supply flow curve unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com