Preheating type fine water mist fire extinguishing system and fine water atomizing nozzle

A fire-extinguishing system and atomizing nozzle technology, used in fire rescue, fire alarms that rely on radiation effects, etc., can solve problems such as suffocating environment and water mist fire extinguishing difficulties, achieve high fire-extinguishing performance and reduce loss of life and property. Risk, effect of reducing oxygen levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

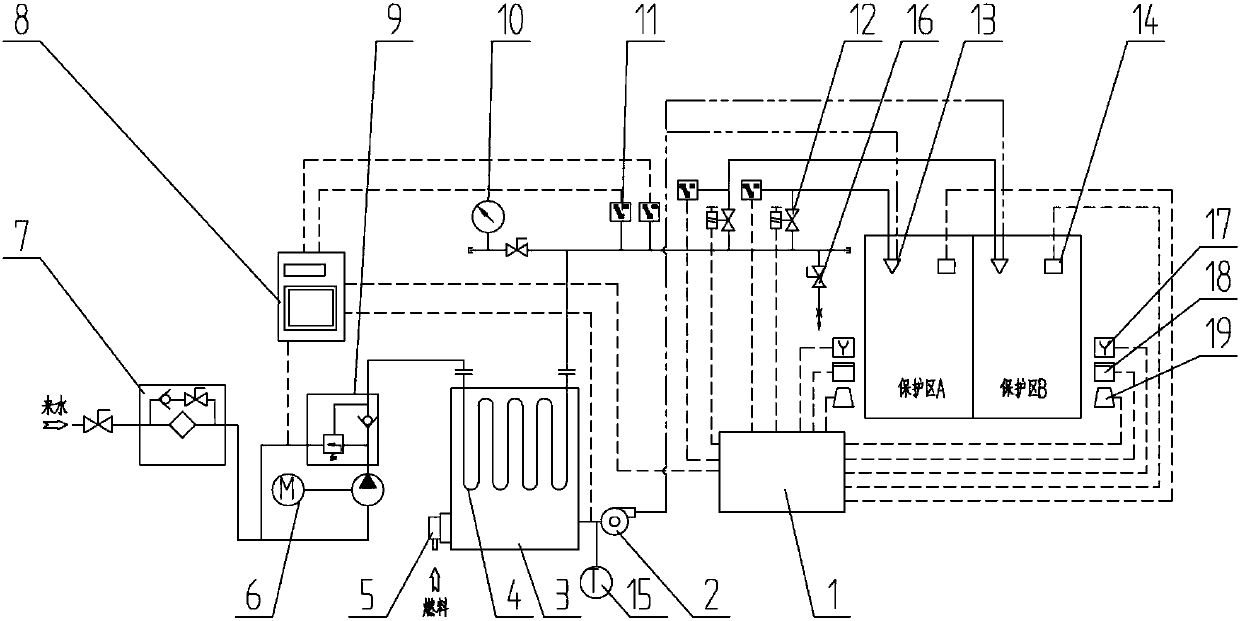

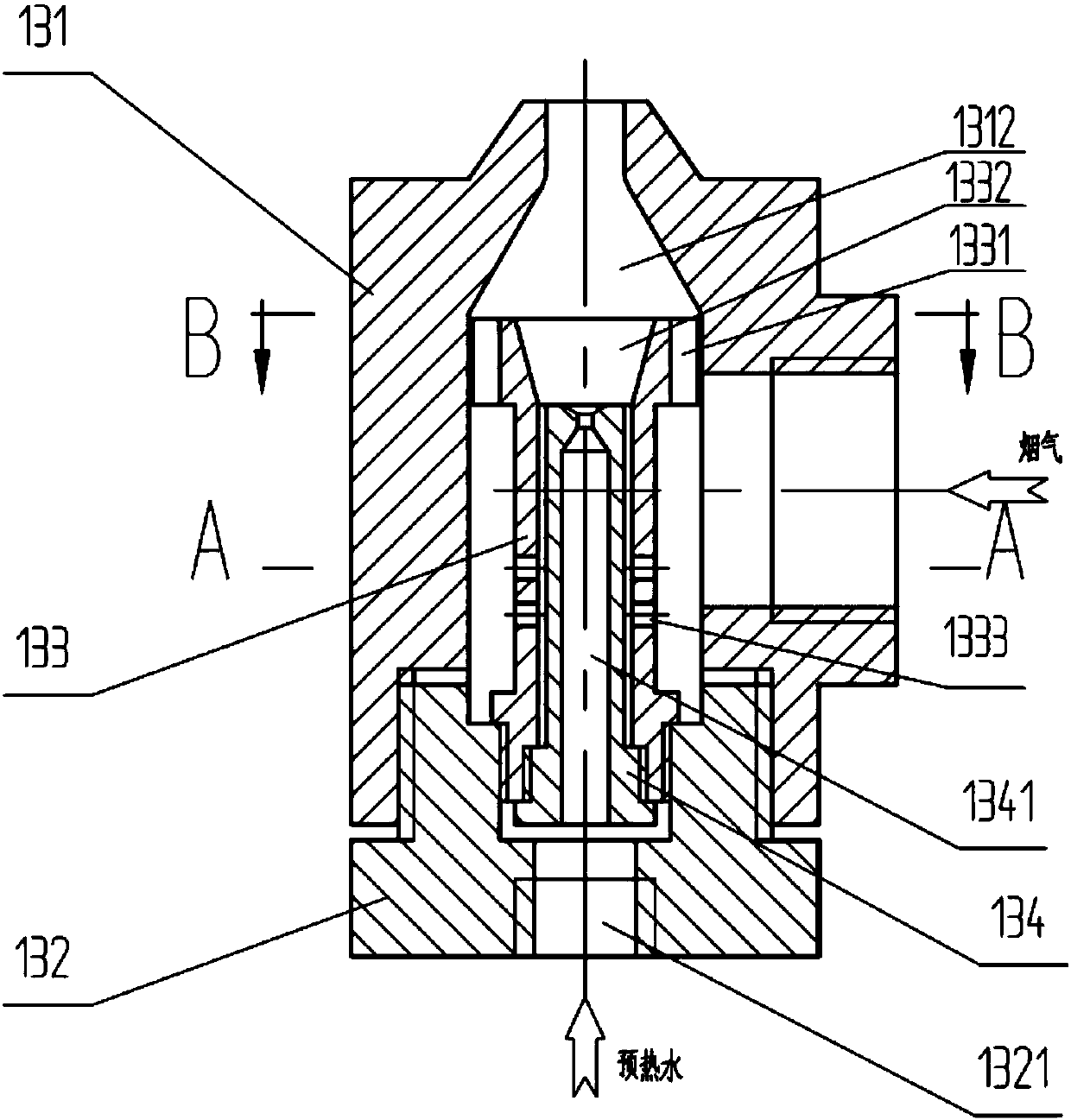

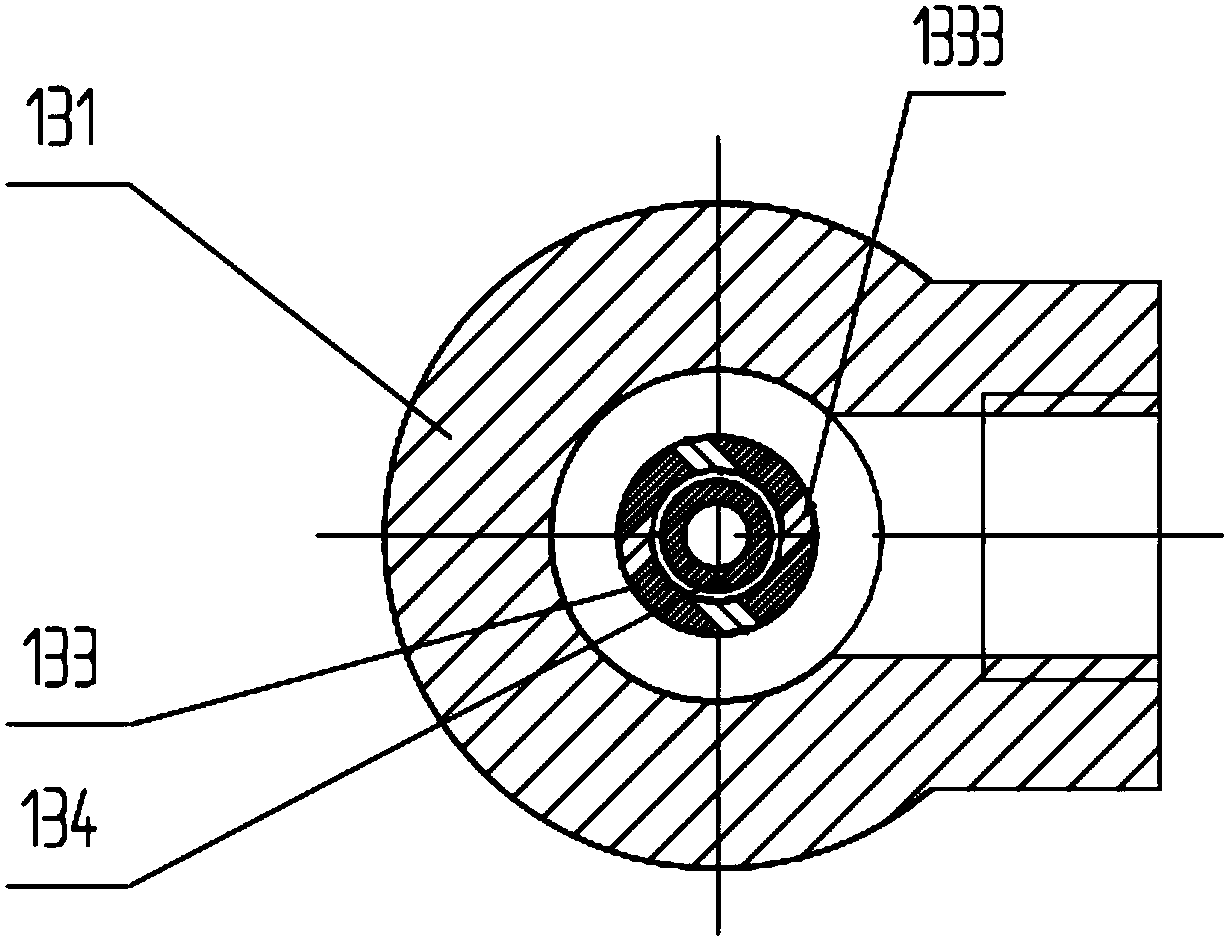

[0029] Such as Figure 1 to Figure 6 A preheated water mist fire extinguishing system shown includes a fire alarm device 1, a control device 8 and a fire extinguishing system, and the control device 8 is used to control the fire alarm device 1 and the fire extinguishing system; the fire extinguishing system includes Filter 7, pump unit 6, heat exchanger 4 and fine water atomizing nozzle 13; heat exchanger 4 is arranged in heating furnace 3, and heating furnace 3 heats the liquid in the furnace through burner 5 to heat exchanger 4 for heat exchange or the high-temperature gas and smoke generated by the burner 5 flush the heat exchanger 4 for heat exchange, and the burner 5 is connected to the fine water atomization nozzle 13 through the induced draft fan 2; the heat exchanger 4 is connected to the fine water atomization nozzle 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com