Combustible energy regeneration system and method thereof

A regenerative system and energy technology, applied in the direction of combustion method, manufacture of combustible gas, combustion type, etc., can solve the problems of respiratory and tracheal diseases, inability to be fully incinerated, and poor incineration efficiency of incinerators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

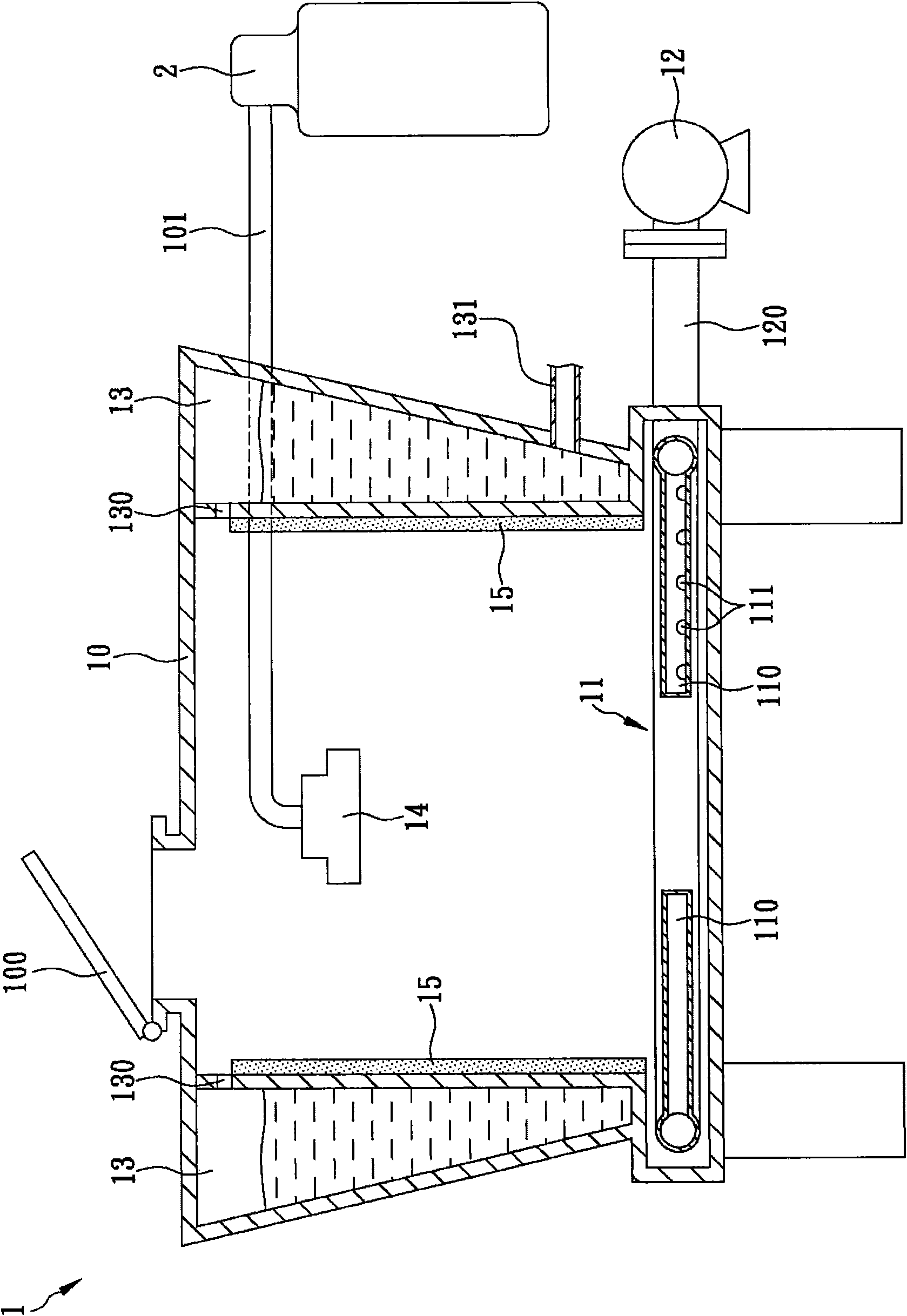

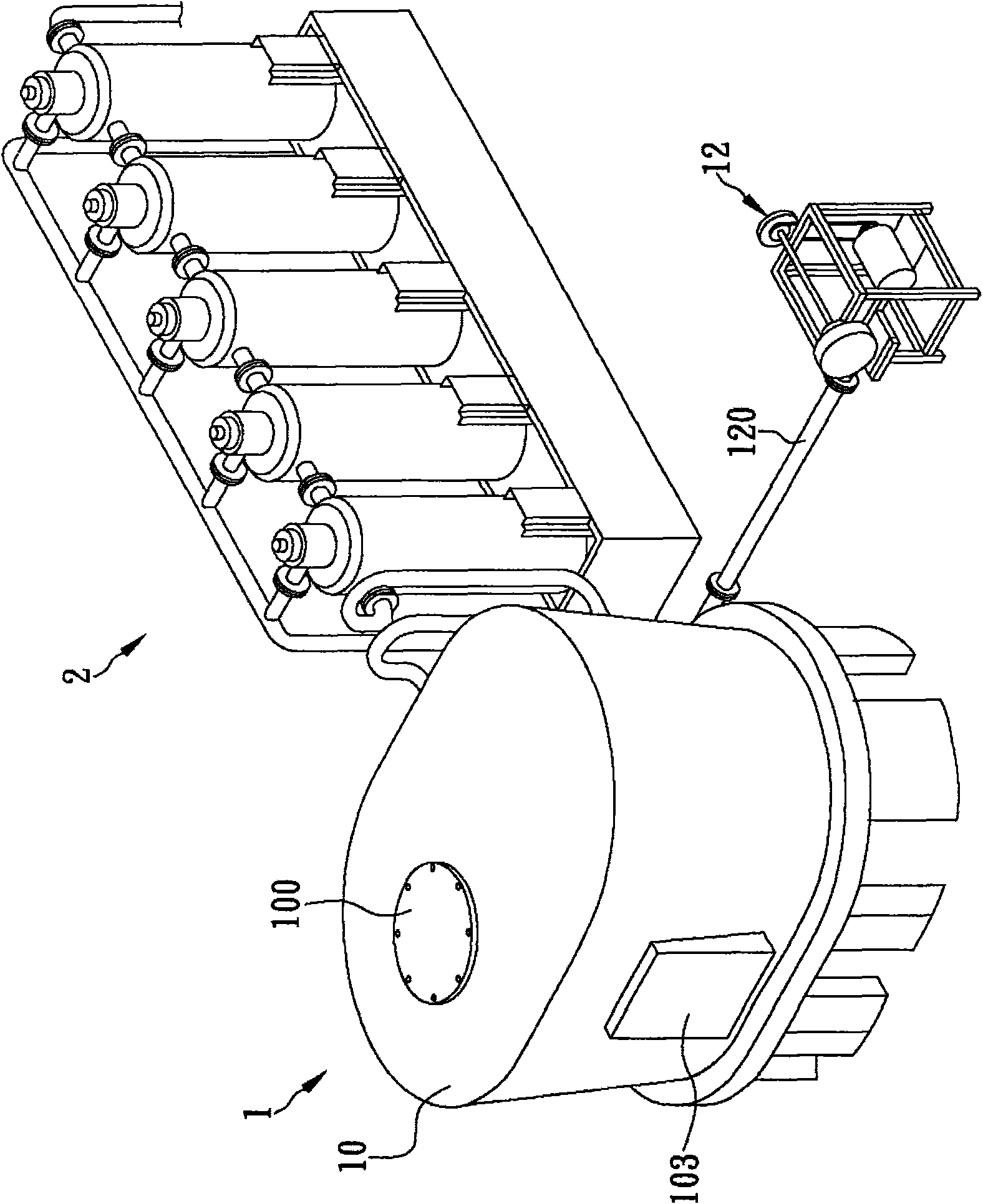

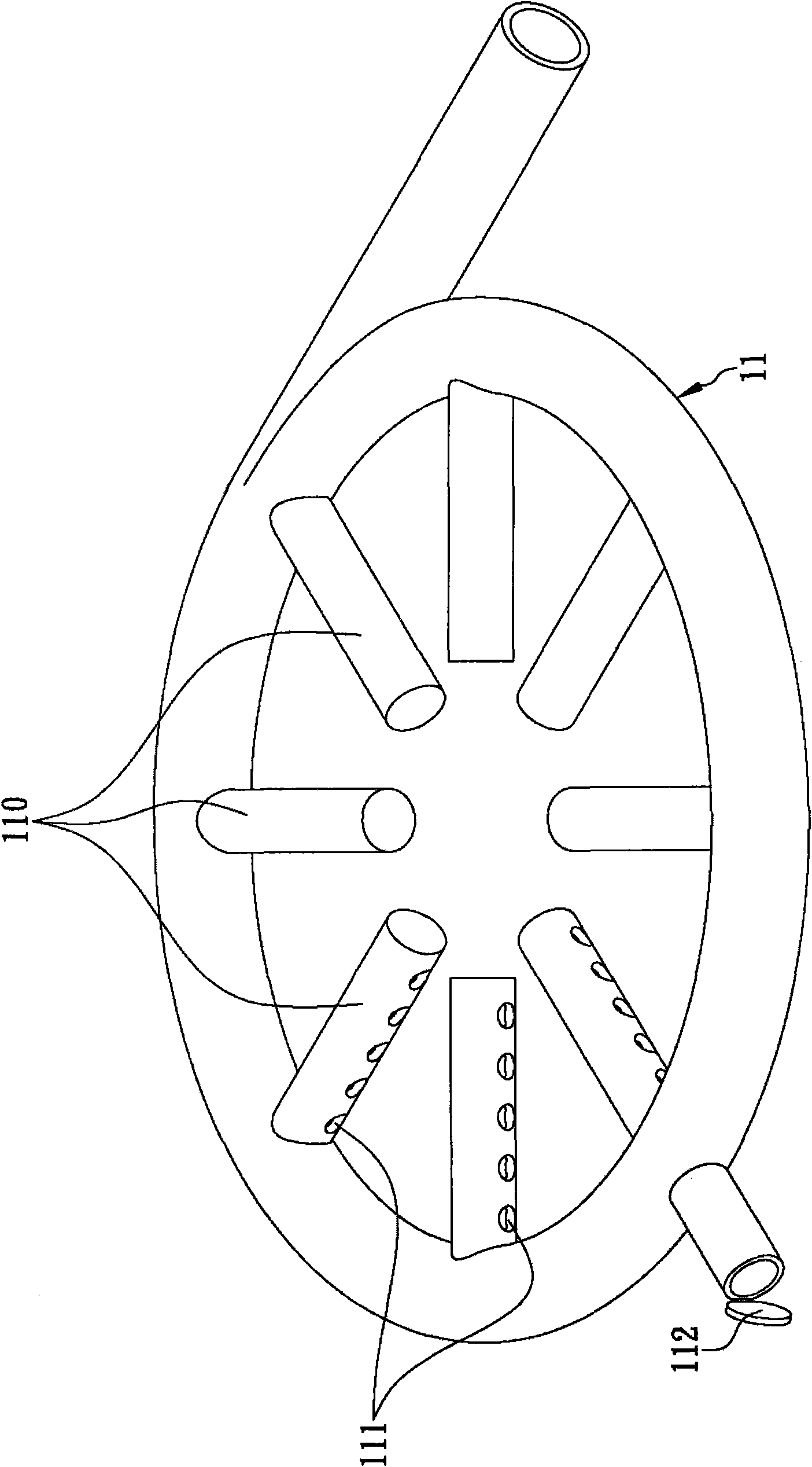

[0042] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0043] After incineration and smoldering of waste materials (such as: waste wood, cloth or plastic, etc.), a large amount of carbon dioxide (CO2) will be produced. 2) and carbon (C), the moisture (H 2 O) will also be evaporated into water vapor due to heat. In addition, when carbon dioxide and carbon produce an endothermic reaction, a flammable energy source of carbon monoxide (CO) will be produced, and when water vapor and carbon produce endothermic During the reaction, carbon monoxide and hydrogen gas (H 2 ) and other combustible energy sources. Therefore, based on this principle, the inventors have developed a combustible energy regeneration system and its method of the present invention through repeated design and testing to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com