Low-temperature smouldering pyrolysis device for sludge

A low-temperature, sludge technology, applied in the direction of pyrolysis treatment of sludge, vaporization of by-products, etc., can solve the problems of low sludge treatment efficiency, complicated operation, and insufficient use of useful components of sludge, so as to improve energy utilization efficiency , avoid harmful substances, the effect of long path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

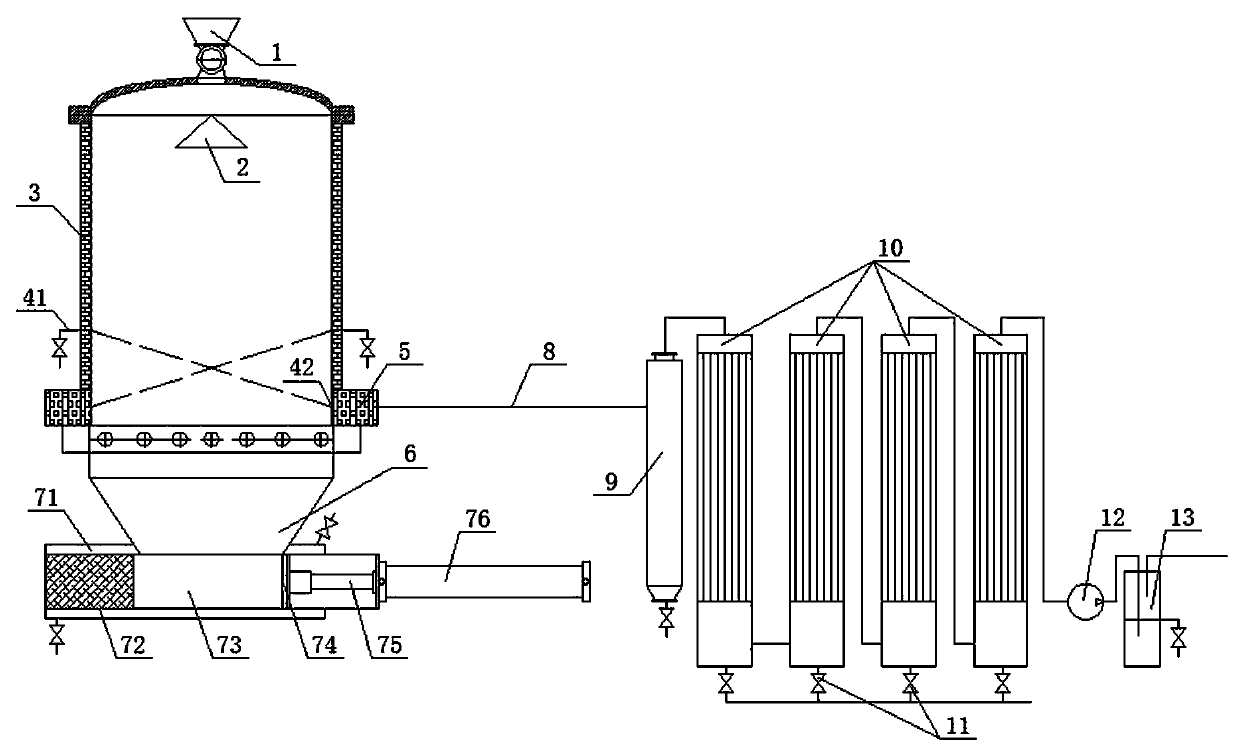

[0022] The present invention is further described below in conjunction with the accompanying drawings.

[0023] like figure 1 As shown, the present invention comprises a pyrolysis furnace body 3, an airtight feeder 1 is provided at the top of the pyrolysis furnace body 3, a slagging device 6 is provided at the bottom of the pyrolysis furnace body 3, and a slag outlet of the slagging device 6 A carbon slag processor is equipped at the place; in the pyrolysis furnace body 3, a distributor 2 located directly below the airtight feeder 1 is provided, and a plurality of suction gas groups are arranged around the circumference at the bottom of the side wall of the pyrolysis furnace body 3, so that Said suction gas group comprises an air inlet 41 and an air outlet 42, and said air inlet 41 is positioned above the air outlet 42 and the air inlet 41 and the air outlet 42 are positioned on the opposite sides of the pyrolysis furnace body 3, during pyrolysis The furnace body 3 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com