Yellow tea smouldered by electrolysis, and preparation method and application of yellow tea

A technology of stuffy yellow and conductive packs, which is applied in the direction of tea treatment before extraction, can solve the problems of large pack stuffing, physical discomfort, low universality, etc., and achieve the effect of improving product quality, good business prospects, and high scientificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

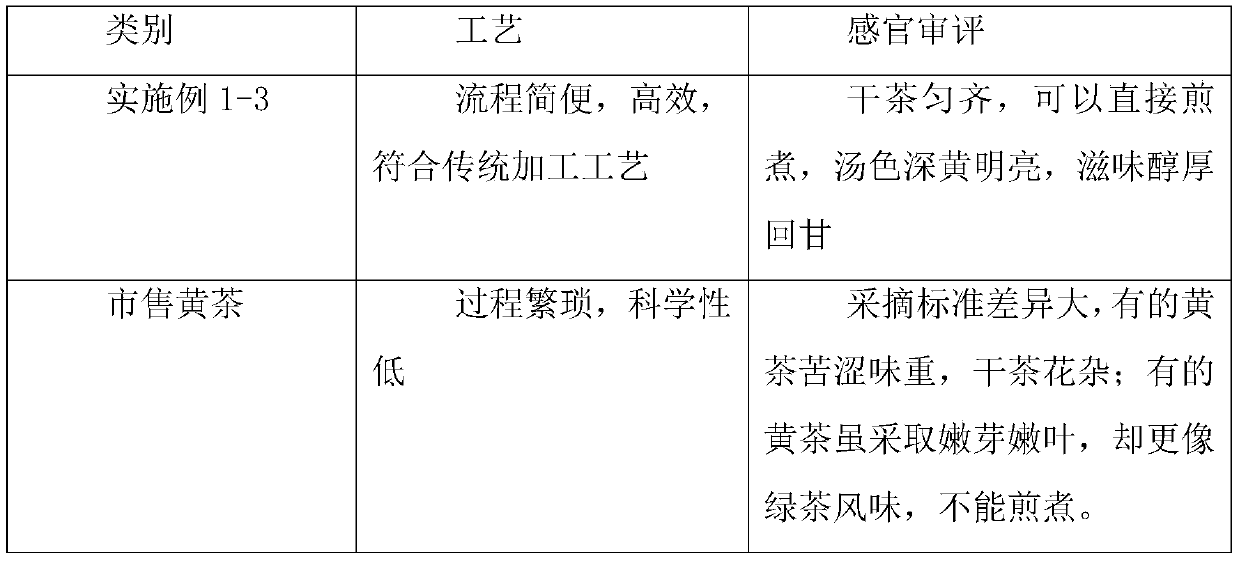

Examples

Embodiment 1

[0017] Embodiment 1 proposes a kind of stuffy yellow tea, comprises the steps:

[0018] (1) First, the yellow tea leaves are ventilated and aired in a withering tank at a temperature of 10° C., and turned every 2 hours for 10 times.

[0019] (2) Use a roller to carry out gradient deenzyming of the yellow tea leaves after being aired; the steps of gradient deenzyming are: firstly deenzyme at 130°C for 1min, then at 125°C for 1min, then at 120°C for 1min, and finally Kill at a temperature of 115°C for 1min.

[0020] (3) Knead the finished yellow tea leaves for 12 minutes until tea juice is produced.

[0021] (4) Disassemble the yellow tea leaves kneaded in step (3) and put them into a container for compaction, then insert 5 copper wires, ground the other end of one of the copper wires, and connect the remaining 2 copper wires to the ground. Electricity, keep at room temperature for 3 days, carry out conduction insulation.

[0022] (5) deblocking the yellow tea leaves that hav...

Embodiment 2

[0024] Embodiment 2 proposes a kind of stuffy yellow tea, comprises the steps:

[0025] (1) Firstly, the yellow tea leaves are ventilated and aired in a withering tank at a temperature of 25° C., and turned once every 2 hours for 5 times.

[0026] (2) Use a roller to carry out gradient deenzyming of the yellow tea leaves after being aired; the step of gradient deenzyming is: first deenzyming at 125°C for 2min, then deenzyming at 120°C for 2min, then deenzyming at 115°C for 2min, and finally Finish at 110°C for 2 minutes.

[0027] (3) Knead the finished yellow tea leaves for 8 minutes until tea juice is produced.

[0028] (4) Disassemble the yellow tea leaves kneaded in step (3) and put them into a container for compaction, then insert 9 copper wires, ground the other end of one of the copper wires, and connect the remaining 2 copper wires to the ground. Electricity, kept at room temperature for 2 days, conduct conductive insulation.

[0029] (5) deblocking the yellow tea le...

Embodiment 3

[0031] Embodiment 3 proposes a kind of stuffy yellow tea, comprises the steps:

[0032] (1) Firstly, the yellow tea leaves are ventilated and aired in the withering tank at a temperature of 17° C., and turned once every 2 hours, and turned 8 times.

[0033] (2) Use a roller to carry out gradient deenzyming of the yellow tea leaves after being aired; the steps of gradient deenzyming are: firstly deenzyme at a temperature of 128°C for 1min, then at a temperature of 123°C for 2min, then at a temperature of 118°C for 1min, and finally Finish at a temperature of 112°C for 2 minutes.

[0034] (3) Knead the finished yellow tea leaves for 10 minutes until tea juice is produced.

[0035] (4) Disassemble the yellow tea leaves that have been kneaded in step (3) and put them into a container for compaction, then insert 7 copper wires, ground the other end of one of the copper wires, and connect the remaining 2 copper wires to the ground. Electricity, kept at room temperature for 2 days,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com