Straw gasification furnace capable of continuously producing gas

A straw and furnace technology, applied in fixed bed gasification, manufacture of combustible gas, petroleum industry, etc., can solve problems such as continuous gas supply and gas furnace flameout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

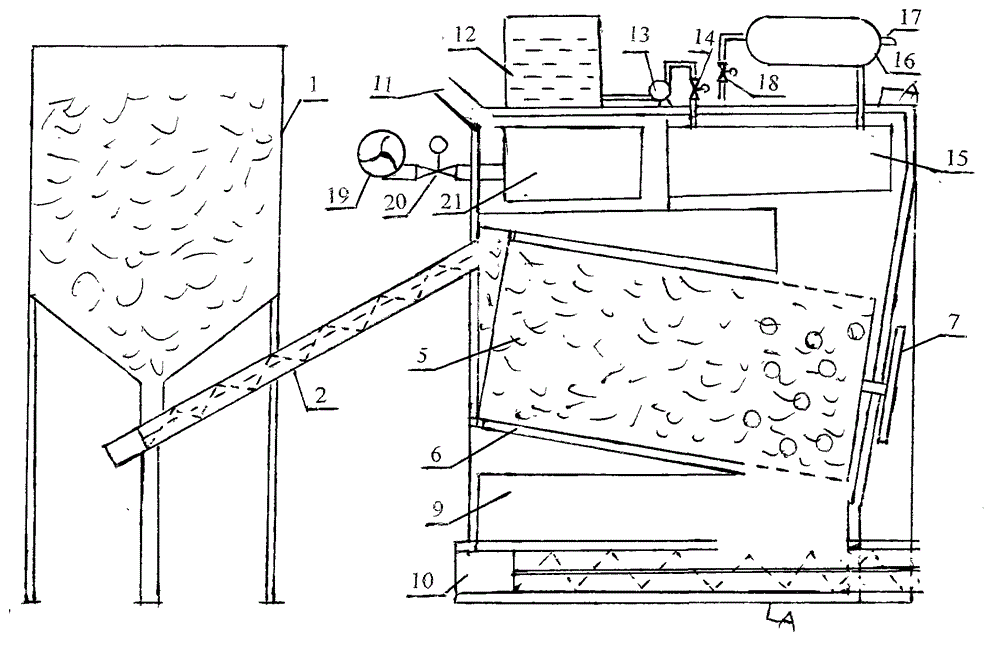

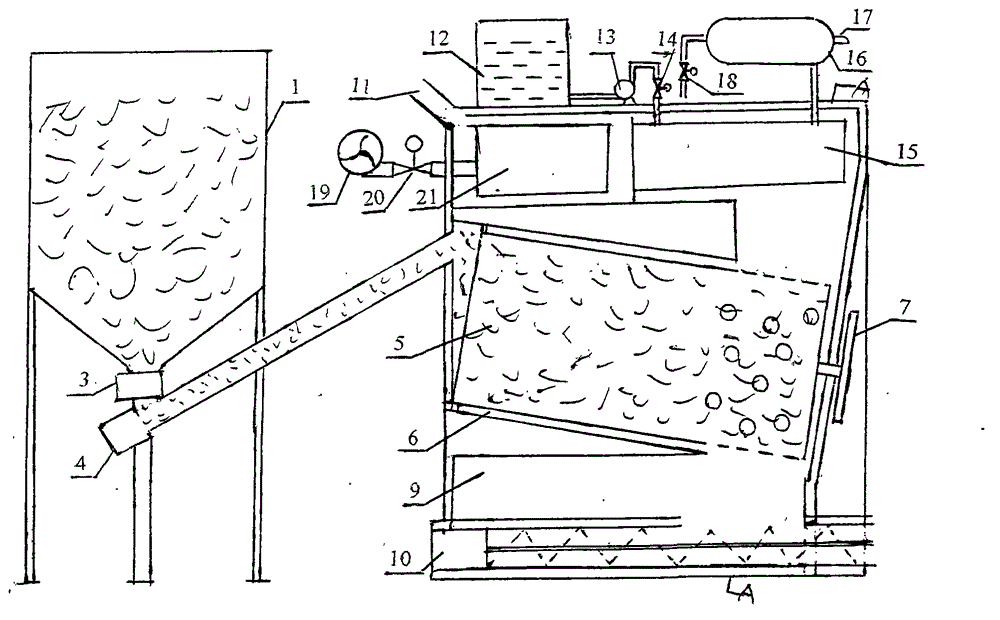

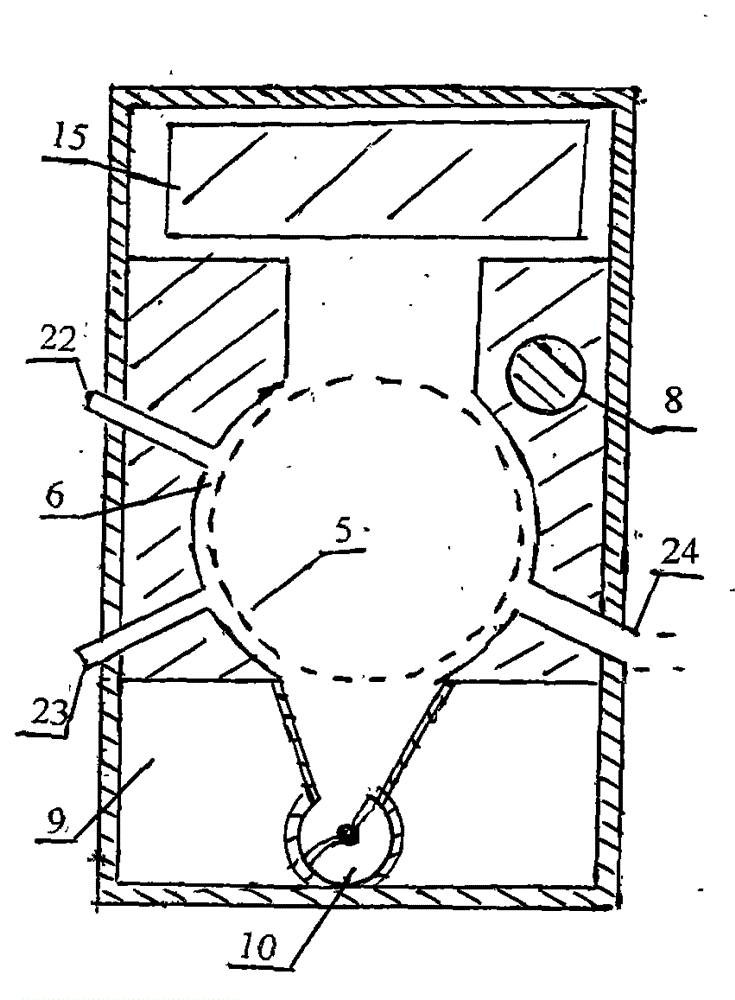

[0012] figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 shown. The straw gasification furnace capable of continuous gas production in the present invention mainly consists of a casing, a furnace 6, ash chamber 9, a screw ash conveyor 10, a drum type furnace rake 5, a driving motor 8, a driving gear, a driven gear 7, and a water tank 12 , water pump 13, electric regulating water valve 14, boiler 15, steam storage tank 16, electric regulating steam valve 18, blower 19, electric regulating gas valve 20, gas heater 21, exhaust pipe 11, air outlet pipe 24, furnace temperature gauge , hygrometer and computer control instrument. The hearth 6 is fired by refractory ceramics, and the outside of the hearth 6 is covered with heat-insulating material and iron shell. The ash chamber 9 is equipped with a screw ash conveyor 10. The hearth 6 is above the ash chamber 9 and communicates with the ash chamber 9. The smoke exhaust pipe 11 is connected from the top of the furnace 6, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com