Method for coke dry quenching by coal internal heat smouldering

A dry coke quenching and low temperature technology, applied in the direction of indirect heating dry distillation, coke cooling, coke oven, etc., can solve the problems of lower gas calorific value, lower energy utilization efficiency, and unoptimized operating system, so as to reduce combustion products and nitrogen The effect of content and moisture reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

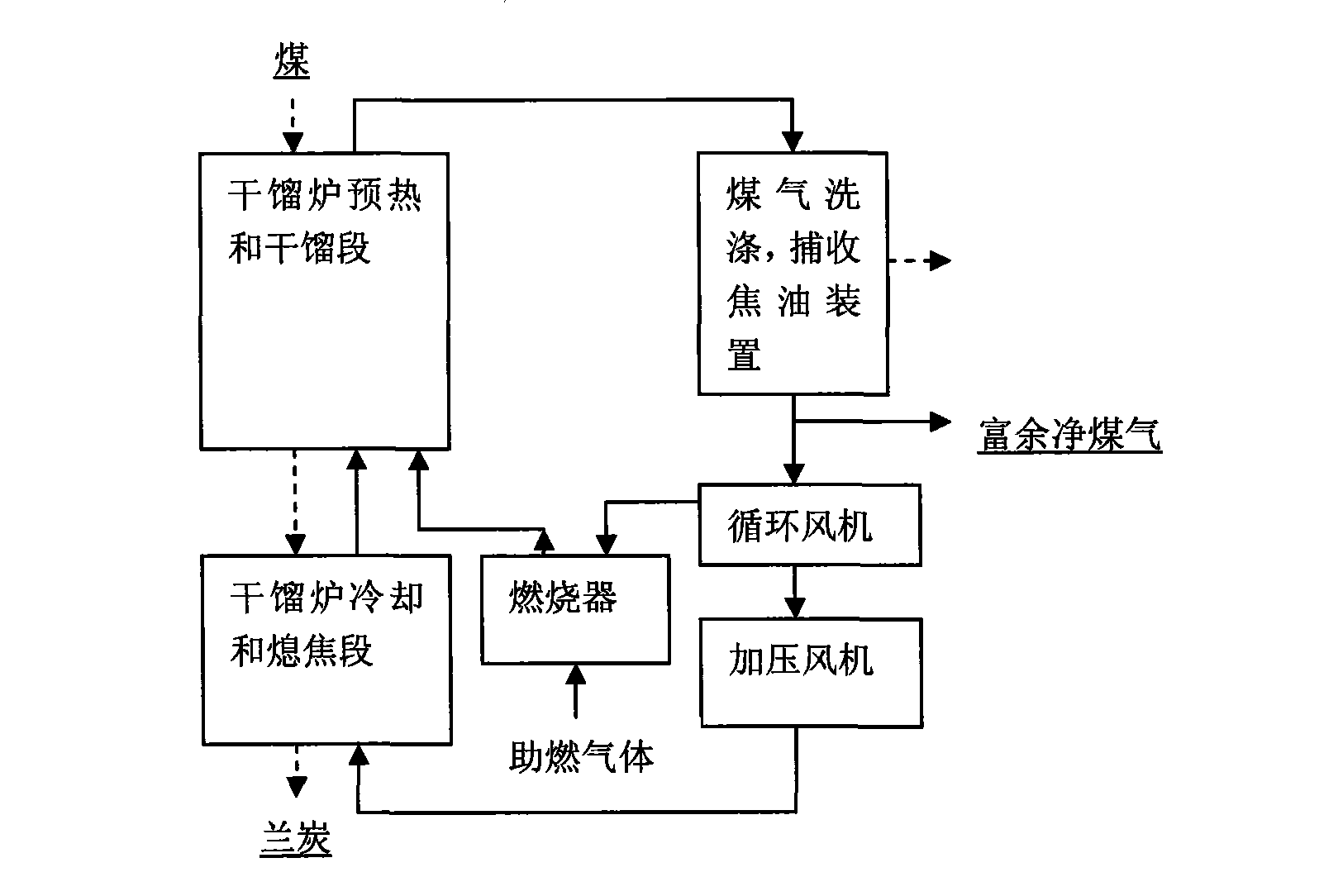

[0030] The specific implementation method is: after the gas produced by dry distillation is separated and collected by tar, according to the technical requirements of dry distillation, part of the cold purified gas is returned to the dry distillation furnace through a circulating fan, and part of it is used to burn with combustion-supporting air (or oxygen) to generate high temperature , into the carbonization furnace from the lower part of the carbonization section of the carbonization furnace; the other part is introduced into the coke quenching section in the lower part of the carbonization furnace through a pressurized fan. The heated gas goes up from the upper part of the quenching section, enters the lower part of the carbonization section, and mixes with the high-temperature gas generated by combustion to form gas that meets the temperature and flow rate required by low-temperature carbonization. In order to ensure the cooling of the coke quenching process and the unifor...

Embodiment 1

[0034] Embodiment 1: the application of annual processing 600,000 tons semi-coke production plant

[0035] (1) Basic information:

[0036] The semi-coke production plant with an annual processing capacity of 600,000 tons adopts a vertical square furnace as the basic production equipment, air-assisted combustion, and a coal-to-coke ratio of 1.65:1. The tar yield is about 8%, and the combustion and circulation gas volume is 349Nm 3 / t 兰炭 , the amount of combustion air into the furnace is 190m 3 / t 兰炭 , The amount of gas used for drying is 35Nm 3 / t 兰炭 , the remaining gas volume per ton of coal is 460Nm 3 / t 兰炭 About (Shenmu dry-based raw coal as the benchmark), gas calorific value 6771-7106kJ / Nm 3 . The reference gas composition is as follows:

[0037] h 2 : 16.2%, CO: 14.49%, CO 2 : 7.41%, CH 4 : 5.68%, Nitrogen: 50.10%. Calorific value: 7029kJ / m 3 .

[0038] (2) Application method

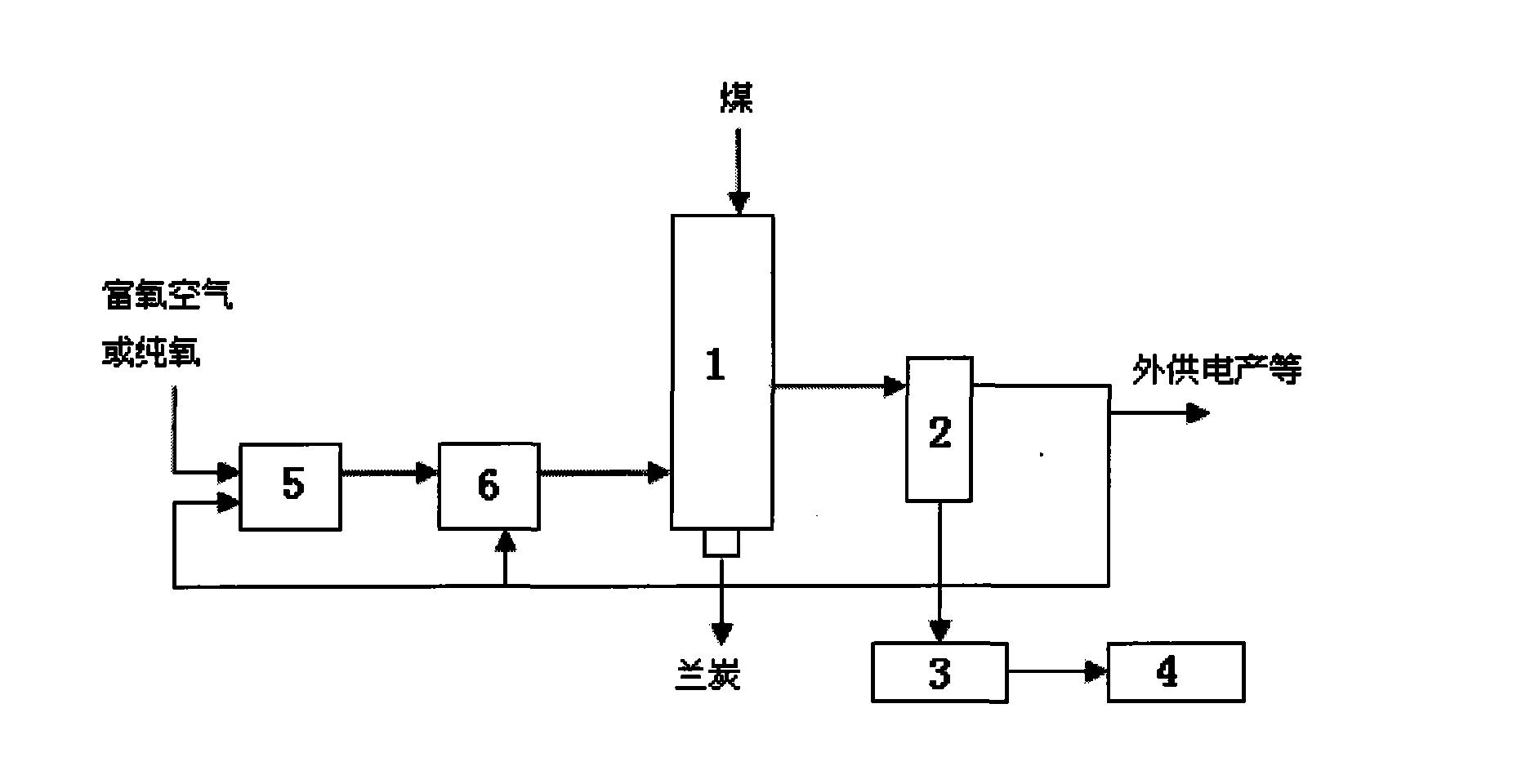

[0039] Applied as figure 2shown. The high-temperature dry distillation gas ...

Embodiment 2

[0043] Embodiment 2: the application of the semi-coke production plant with an annual output of 600,000 tons

[0044] (1) Basic information

[0045] The semi-coke production plant with an annual processing capacity of 600,000 tons uses a vertical square furnace as the basic production equipment, with oxygen-enriched air for combustion, an oxygen-enriched ratio of 80%, a coal-to-coke ratio of 1.65:1, and a tar yield of about 8%. Combustion and circulating gas volume 519m 3 / t 兰炭 , the amount of oxygen-enriched air in the furnace is 50m 3 / t 兰炭 , The amount of gas used for drying is 35Nm 3 / t 兰炭 , the remaining gas volume per ton of coal is 260Nm 3 / t 兰炭 About (Shenmu dry-based raw coal as the benchmark), the calorific value of gas is 13102kJ / Nm 3 . The reference gas composition is as follows:

[0046] h 2 : 35.05%, CO 23.04%, CO 2 : 12.06%, CH 4 : 12.55%, Nitrogen: 9.85%. Calorific value of gas 13102kJ / m 3 .

[0047] (2) Application method

[0048] The applicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com