Porous carbon nanofiber membrane for positive electrode material of lithium-sulfur battery and preparation method thereof

A nanofiber membrane, cathode material technology, applied in battery electrodes, lithium storage batteries, nanotechnology for materials and surface science, etc., can solve the problem of poor production stability, low cost, and low electrospinning production efficiency of solution jet technology. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 1 g of polyvinyl alcohol into 9 mL of distilled water, and keep stirring to make it fully swell, then put it into a constant temperature oil bath at 90°C, and stir while heating to obtain a polyvinyl alcohol solution. Dissolve 0.4g of boric acid in 10g of water at room temperature. Take 30 μL of boric acid with a micro-syringe and add it to 25 g of tetrafluoroethylene aqueous emulsion, mix evenly, and then blend with polyvinyl alcohol solution reduced to room temperature to prepare a spinning solution with a mass ratio of polyvinyl alcohol polyvinyl alcohol to tetrafluoroethylene of 1:15. .

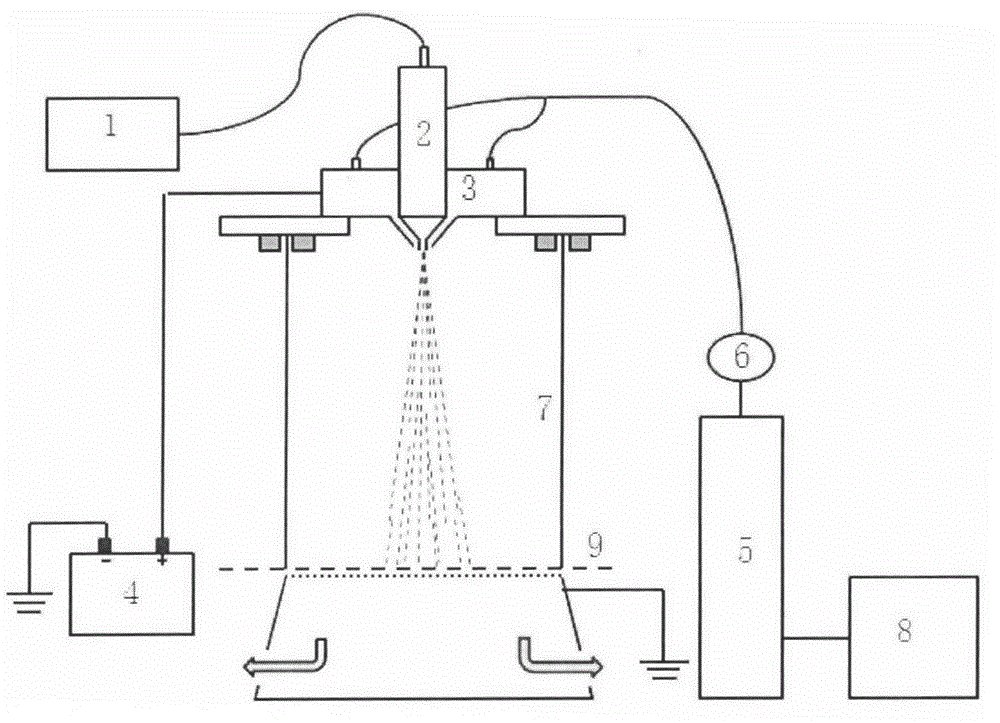

[0029] The above spinning solution is added to such as figure 1 In the spinning device, the device includes: 1 metering injection pump, 2 liquid storage tank, 3 spinneret, 4 high voltage power supply, 5 air storage tank, 6 pressure regulating valve, 7 spinning tunnel, 8 air compressor, 9 receiving Net curtain composition. Spinning process parameters are set as follows: air f...

Embodiment 2

[0033] Add 0.8 g of polyvinyl alcohol into 9.2 mL of distilled water, and keep stirring to make it fully swell, then put it into a constant temperature oil bath at 90°C, and stir while heating to obtain a polyvinyl alcohol solution. Dissolve 0.3g of boric acid in 10g of water at room temperature. Take 15 μL of boric acid with a micro-syringe and add it to 12 g of tetrafluoroethylene aqueous emulsion, mix evenly, and then blend with polyvinyl alcohol solution restored to room temperature to prepare a spinning solution with a mass ratio of polyvinyl alcohol polyvinyl alcohol to tetrafluoroethylene of 1:9. .

[0034] Add the above spinning solution into the spinning device, the spinning process parameters are: air flow rate 0.06MPa, spinning voltage 25kV, receiving distance 50cm, extrusion rate 40mL / h, spinning for a certain period of time to obtain polyvinyl alcohol / polyethylene tetrachloride Vinyl fluoride / boric acid composite microfiber.

[0035] The obtained composite micro...

Embodiment 3

[0038] Add 1.2 g of polyvinyl alcohol into 8.8 mL of distilled water, and keep stirring to make it fully swell, then put it into a constant temperature oil bath at 90°C, and stir while heating to obtain a polyvinyl alcohol solution. Dissolve 0.5g of boric acid in 10g of water at room temperature. Take 45 μL of boric acid with a micro-syringe and add it to 24 g of tetrafluoroethylene aqueous emulsion, mix evenly, and then blend with polyvinyl alcohol solution restored to room temperature to prepare a spinning solution with a mass ratio of polyvinyl alcohol polyvinyl alcohol to tetrafluoroethylene of 1:12. .

[0039] Add the above spinning solution into the spinning device, the spinning process parameters are: air flow rate 0.14MPa, spinning voltage 45kV, receiving distance 50cm, extrusion rate 30mL / h, spinning for a certain period of time to obtain polyvinyl alcohol / polyethylene tetrachloride Vinyl fluoride / boric acid composite microfiber.

[0040] The obtained composite micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com