Internal combustion horizontal rotary continuous carbonization furnace

An internal combustion horizontal carbonization furnace technology, which is applied to coke ovens with horizontal carbonization chambers, rotary carbonization furnaces, coke ovens, etc., can solve the problems of low manufacturing cost and blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

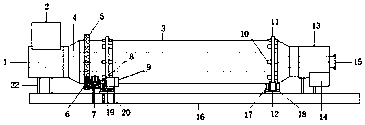

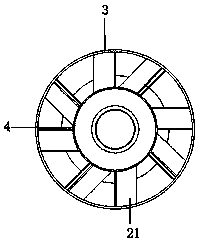

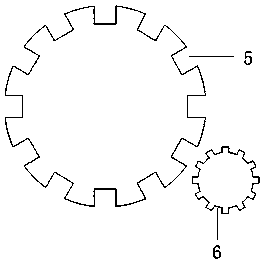

[0020] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical scheme: an internal combustion horizontal rotary continuous carbonization furnace, including a feed end 1, and a feed port 2 is fixedly connected to the feed port 1, and the feed port 2 is connected to the feed port 2. The ends 1 are connected to each other, and an inner drum 4 is inserted inside the feed end 1 below the feed port 2, and an outer drum 3 connected coaxially is set on the outside of the inner drum 4, and the inner drum 4 is connected to the outer drum. Between the outer walls of the drum 3 is a material carbonization space, and a number of deflectors 21 are welded between the inner drum 4 and the outer drum 3, and a number of fixing plates 10 are arranged on the outside of the outer drum 3, and one side of the fixing plate 10 It is fixedly welded with the outer drum 3, and the fixed plate 10 is fixedly connected with a large gear 5 on the other side of the outer drum 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com