High-purity viscose fiber and preparation method thereof

A viscose fiber and high-purity technology, applied in the field of viscose fiber, can solve the problems of high-purity viscose fiber with low ash content, low ash content, elongation at break, and low actual carbon yield, and achieve low cost and carbon High yield and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

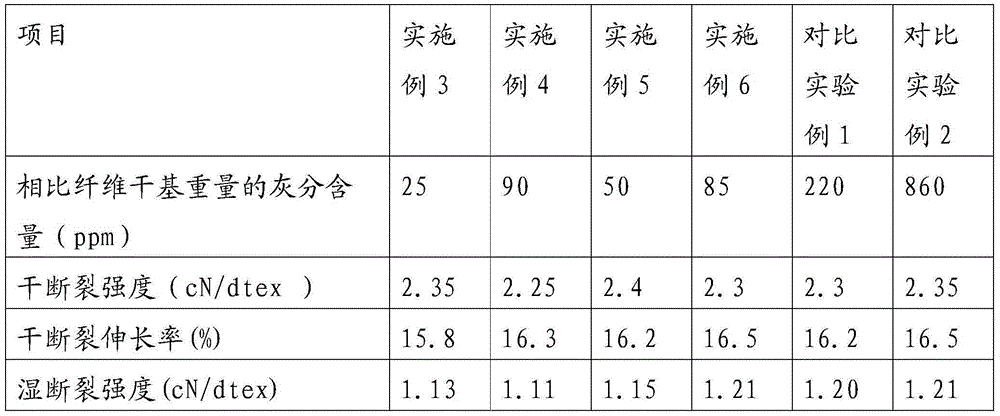

Examples

Embodiment 1

[0028] A kind of high-purity viscose fiber, ash content accounts for the 55ppm of high-purity viscose fiber dry basis weight in the described high-purity viscose fiber; The dry breaking strength of described high-purity viscose fiber is 2.5cN / dtex, and dry breaking elongation The rate is 17.5%, and the wet breaking strength is 1.13cN / dtex.

Embodiment 2

[0030] A high-purity viscose fiber, the ash content in the high-purity viscose fiber accounts for 80ppm of the high-purity viscose fiber dry basis weight; the dry breaking strength of the high-purity viscose fiber is 2.35cN / dtex, and the dry breaking elongation The rate is 16.5%, and the wet breaking strength is 1.2cN / dtex.

Embodiment 3

[0032] Using natural cellulose pulp as a raw material, soluble cellulose xanthate is obtained through alkalization, aging, and sulfonation steps, and the soluble cellulose xanthate is dissolved in a dilute alkali solution to prepare a viscose solution, and the viscose The glue solution is filtered and defoamed to obtain spun viscose, and the spun viscose is extruded through a spinneret hole and solidified into spun silk in a coagulation bath.

[0033] After the as-spun silk was drawn, desulfurized and washed with water, it was pre-dipped with hydrochloric acid at room temperature. The concentration of hydrochloric acid used in the pre-dipping was 1.2 g / L, and the pre-dipping time was 5 minutes.

[0034] After the pre-impregnated fibers are bleached and oiled, they are squeezed dry, washed with alcohol at room temperature, and treated with 5 g / l ethanol solution for 10 minutes.

[0035] Squeeze the alcohol-washed fibers to dryness, first carry out the first hydrochloric acid di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com