Method for directionally preparing aromatic hydrocarbon through co-pyrolysis of biomass and plastic

A biomass and co-pyrolysis technology, applied in the field of biomass resource utilization, can solve the problems of affecting the mass transfer and heat transfer of pyrolysis, difficulty in ensuring synergistic pyrolysis, uneven raw materials, etc., so as to strengthen interaction and improve selection. The effect of increasing the yield of aromatic hydrocarbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

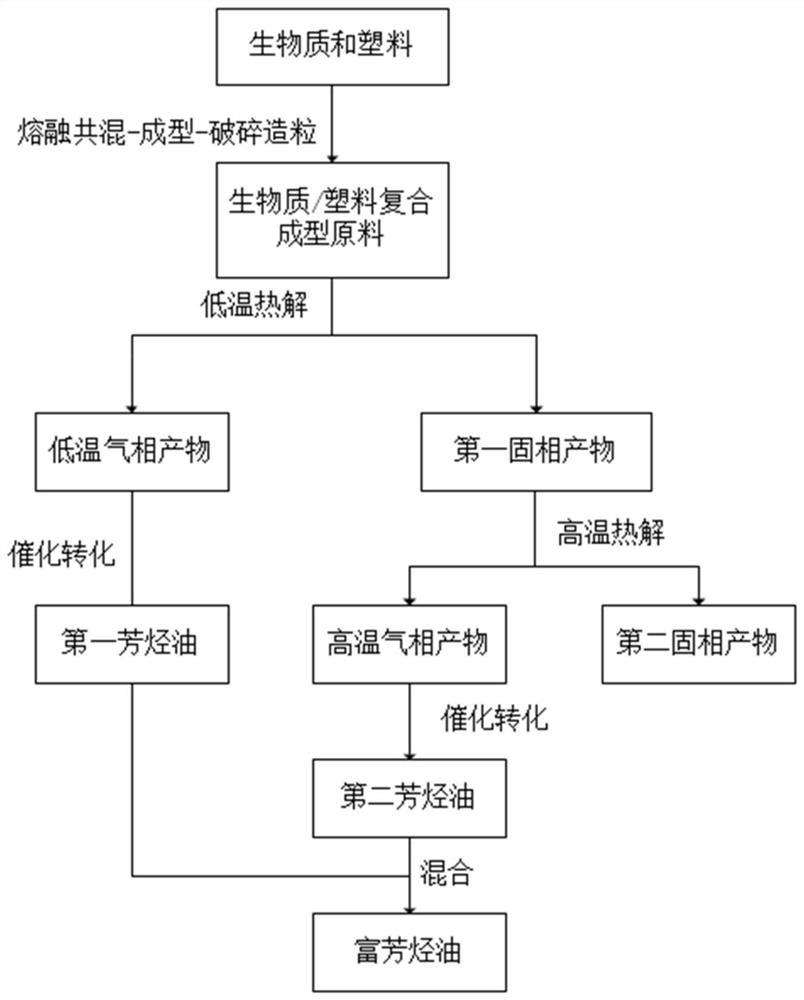

[0061] This embodiment provides a method for the directional preparation of aromatics by co-pyrolysis of biomass and plastics. The process flow diagram of the method is as follows figure 1 shown.

[0062] The method comprises the steps of:

[0063] (1) Put the fruit shell and low-density polyethylene plastic in a preheater at a mass ratio of 1:1, melt and blend them at 170°C, and then heat press them at 0.5MPa. Crushing and granulating after cooling to obtain biomass / plastic composite molding raw materials;

[0064] (2) The biomass / plastic composite molding raw material obtained in step (1) is subjected to low-temperature pyrolysis treatment at 550°C to obtain a low-temperature gas phase product containing the first pyrolysis oil vapor and the first pyrolysis gas and the first Solid-phase product; the low-temperature pyrolysis gas-phase product is subjected to a catalytic conversion reaction through a HZSM-5 molecular sieve catalyst bed at 750°C, and aromatic first hydrocarb...

Embodiment 2

[0068] This embodiment provides a method for the directional preparation of aromatics by co-pyrolysis of biomass and plastics, the method comprising the following steps:

[0069] (1) Put the straw and polyvinyl chloride plastic in the preheater according to the mass ratio of 1:0.1, carry out melt blending under the condition of 220°C, and then hot press molding under the condition of 0.1MPa, after cooling After crushing and granulating, biomass / plastic composite molding raw materials are obtained;

[0070] (2) The biomass / plastic composite molding raw material obtained in step (1) is subjected to low-temperature pyrolysis treatment at 600°C to obtain a low-temperature gas phase product containing the first pyrolysis oil vapor and the first pyrolysis gas and the first Solid-phase product; the low-temperature pyrolysis gas-phase product is subjected to a catalytic conversion reaction through a ZSM-5 molecular sieve catalyst bed at 700°C, and aromatic first hydrocarbon oil is obt...

Embodiment 3

[0074] This embodiment provides a method for the directional preparation of aromatics by co-pyrolysis of biomass and plastics, the method comprising the following steps:

[0075] (1) Put sawdust and polyvinyl chloride plastic in a preheater with a mass ratio of 1:10, melt and blend them at 120°C, and then heat press them at 5MPa. After cooling, Carry out crushing and granulation to obtain biomass / plastic composite molding raw materials;

[0076] (2) The biomass / plastic composite molding raw material obtained in step (1) is subjected to low-temperature pyrolysis treatment at 450°C to obtain a low-temperature gas phase product containing the first pyrolysis oil vapor and the first pyrolysis gas and the first Solid-phase product; the low-temperature pyrolysis gas-phase product is subjected to a catalytic conversion reaction through a HZSM-5 molecular sieve catalyst bed at 500°C, and aromatic first hydrocarbon oil is obtained after condensation and oil-water separation;

[0077] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com