Carbon-iron-titanium-silicon-aluminum oxide compound and preparation method and application thereof

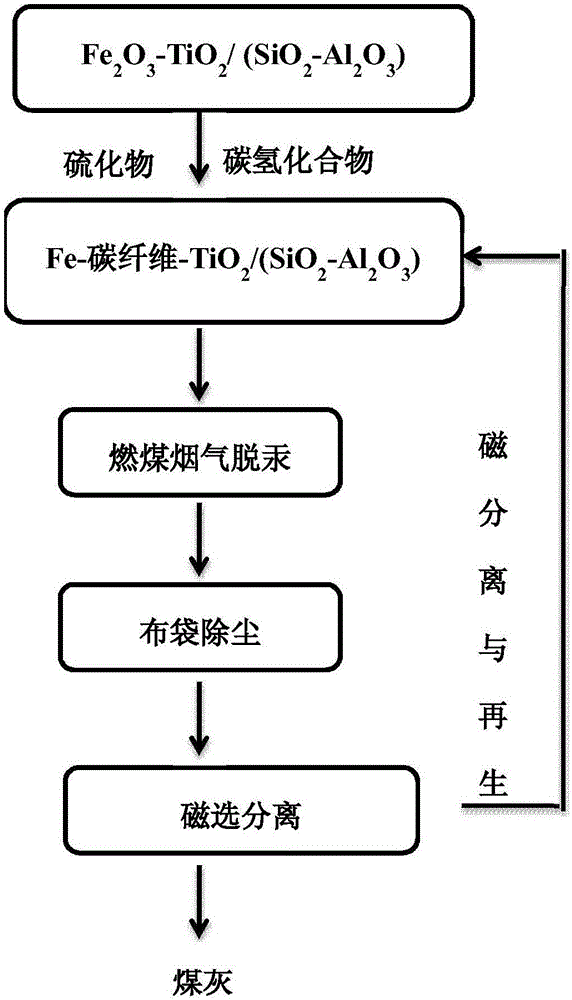

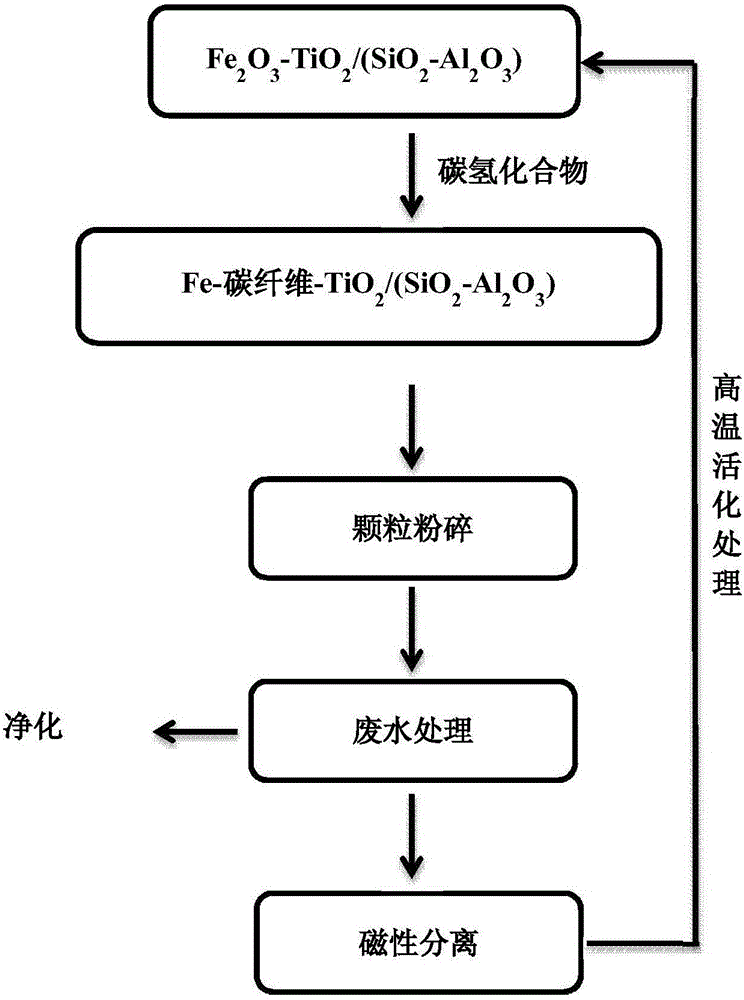

A silicon-aluminum oxide and composite technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, separation methods, etc. Problems such as high carbon yield and large iron particle size have achieved the effects of wide industrial application prospects, high-value utilization, and high activated carbon yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

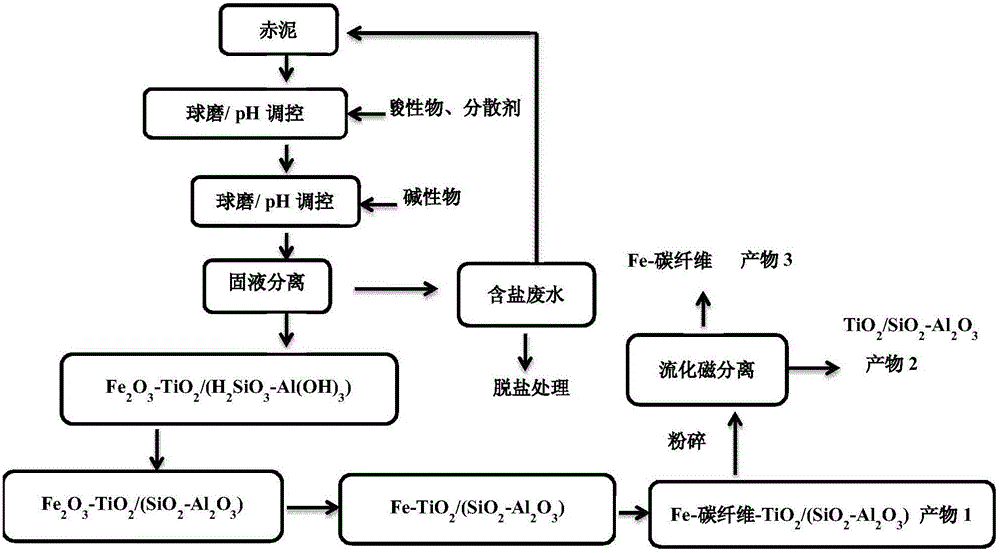

[0048] A preparation method of an iron-titanium-silicon-aluminum oxide compound for depositing carbon fibers, comprising the steps of:

[0049] (1) After adding 1 kg of water to 1 kg of red mud, put it into a ball mill tank and mill it for 12 hours, so that the particle size is less than or equal to 100 nm, and obtain the first slurry, the solid content of the first slurry is 30%;

[0050] (2) After 1 kg of dilute nitric acid solution (10% concentration) was added dropwise in the first slurry, the pH value of the solution was about 2, and the system became slurry; the slurry red mud was added dropwise with ammonia water (10% concentration) during the ball milling process. Concentration) 0.5kg, the pH value of the solution is about 6, the silica-alumina sol precipitates again, the viscosity of the system becomes smaller, and the second slurry is obtained;

[0051] (3) After the second slurry is subjected to solid-liquid separation and washing, it is dried at 120°C, and then roa...

Embodiment 2

[0059] A preparation method of an iron-titanium-silicon-aluminum oxide compound for depositing carbon fibers, comprising the steps of:

[0060] (1) After adding 2 kg of water to 1 kg of red mud, put it into a ball mill tank and mill it for 10 hours, so that the particle size is less than or equal to 100 nm, to obtain the first slurry, the solid content of the first slurry is 20%;

[0061] (2) After dripping dilute hydrochloric acid solution (5%) 1kg successively in the first slurry, the solution pH value is about 4, and the system becomes slurry; Slurry red mud is dripped successively sodium hydroxide (10% in ball milling process) % concentration) after 0.5kg, the pH value of the solution is about 6, the silica-alumina sol precipitates again, the viscosity of the system becomes smaller, and the second slurry is obtained;

[0062] (3) After the second slurry is subjected to solid-liquid separation and washing, it is dried at 100° C., and then roasted at 600° C. for 5 hours to o...

Embodiment 3

[0070] A preparation method of an iron-titanium-silicon-aluminum oxide compound for depositing carbon fibers, comprising the steps of:

[0071] (1) After adding 1 kg of water to 1 kg of red mud, add it to a ball mill tank and mill for 24 hours, so that the particle size is less than or equal to 100 nm, and obtain the first slurry, the solid content of the first slurry is 50%;

[0072] (2) After dripping sulfuric acid solution (50%) 0.2kg successively in the first slurry, the pH value of the solution is about 3, and the system becomes slurry; slurry red mud is dripped with sodium carbonate aqueous solution (5 % concentration) after 1kg, the pH value of the solution was about 7, the silica-alumina sol precipitated again, the viscosity of the system became smaller, and the second slurry was obtained;

[0073] (3) After the second slurry is subjected to solid-liquid separation and washing, it is dried at 100°C, and then calcined at 800°C for 3 hours to obtain a solid substance, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com