Method for extracting oligopeptide from algae to prepare alga oligopeptide powder

A technology of seaweed oligopeptide and oligopeptide, which is applied in the field of extracting peptides from seaweed, can solve the problems of seaweed limitation, achieve the effect of improving utilization rate, reducing impact, and making full use of natural resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Wash Ulva with pure water and dry in the sun;

[0041] 2. Pulverization: take the dried Ulva pulveris and ultrafinely pulverize it, and pass through a 100-mesh sieve;

[0042] 3. Breaking the cell wall: Weigh 1000g of Ulva pore powder, add pure water at a ratio of 1:19, use a colloid mill to refine the slurry, adjust the system temperature to 50°C, pH 3.5, add 0.1g of pectinase (30000u / g) , stirring for 3 hours;

[0043] 4. Enzymolysis: adjust the system temperature to 42°C, pH 7.5, add 5g of compound protease, stir for 4 hours, heat up to 90°C to inactivate the enzyme for 20 minutes, and centrifuge to obtain the clear liquid;

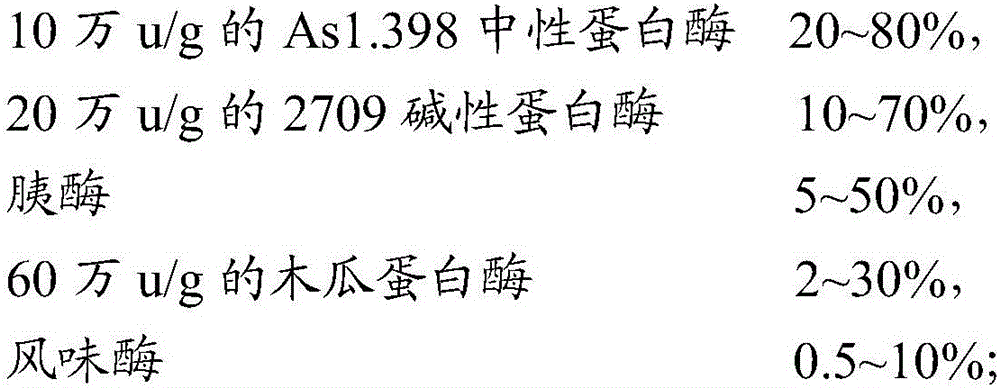

[0044] The composition of compound protease is:

[0045]

[0046] 5. Membrane filtration: filter the clear liquid with a membrane with a pore size of 4nm, dilute the retained liquid with pure water and then filter, repeat 3 times, and combine the permeate, which mainly contains peptides and inorganic ions;

[0047]6. Refining Ulva Pepti...

Embodiment 2

[0052] 1. Wash the sage algae with pure water and dry them in the sun;

[0053] 2. Pulverization: take the dried Sargassum ultrafine pulverization, and pass through a 100-mesh sieve;

[0054] 3. Breaking the cell wall: Weigh 10kg of sargassum powder, add pure water at a ratio of 1:14, refine the slurry with a colloid mill, adjust the system temperature to 52°C, pH 3.7, add 1g of pectinase (30000u / g), Stirring and enzymatic hydrolysis for 3.5h;

[0055] 4. Enzymolysis: Adjust the system temperature to 40°C and pH 8.0, add 100g of protease and stir for 4 hours, heat up to 85°C to inactivate the enzyme for 20 minutes, and centrifuge to obtain the clear liquid;

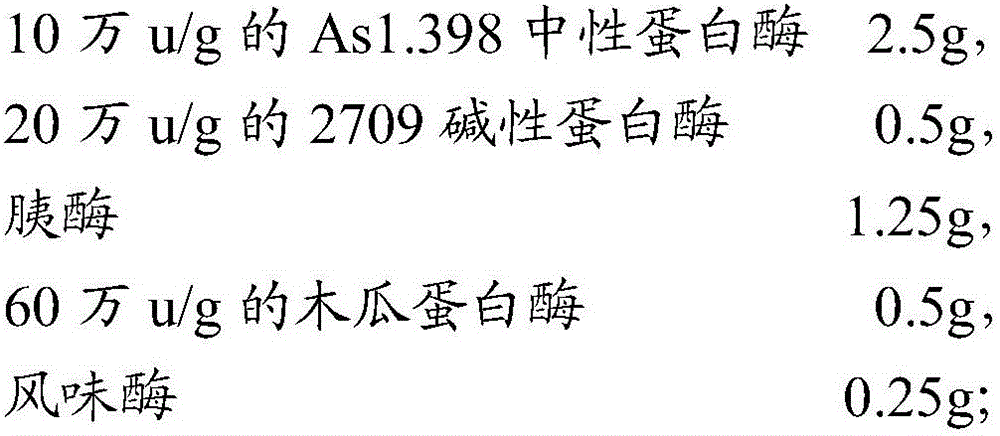

[0056] The composite protease consists of:

[0057]

[0058] 5. Membrane filtration: the clear liquid is filtered with a membrane with a pore size of 5nm, the retained liquid is diluted with pure water and then filtered, repeat 3 times, and the permeate is combined, the permeate mainly contains peptides and inorganic...

Embodiment 3

[0064] 1. Wash wakame with pure water, spread out to dry, and dry at 50°C until constant weight;

[0065] 2. Pulverization: take the dry undaria pinnatifida ultrafine pulverization, and pass through a 100-mesh sieve;

[0066] 3. Breaking the cell wall: Weigh 10kg of wakame powder, add pure water at a ratio of 1:19, refine the slurry with a colloid mill, adjust the system temperature to 56°C, pH 3.9, add 1g of pectinase (30000u / g), and stir Enzymolysis 4h;

[0067] 4. Adjust the temperature of the system to 45°C, pH 8.5, add 120g of compound protease, stir for 5 hours, heat up to 85°C to inactivate the enzyme for 20 minutes, and centrifuge to obtain the clear liquid;

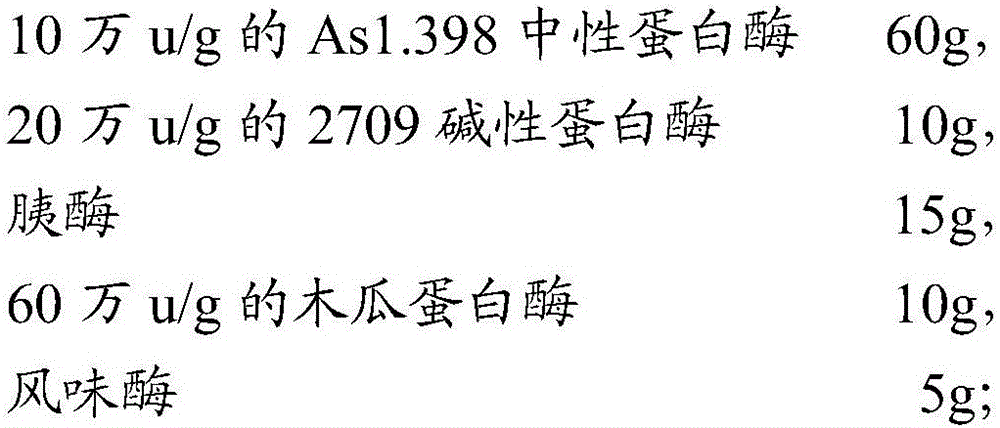

[0068] The mass composition of described composite protease is:

[0069]

[0070] 5. Membrane filtration: the clear liquid is filtered with a membrane with a pore size of 6nm, the retained liquid is diluted with pure water and then filtered, repeated 3 times, and the permeated liquid is combined, mainly cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com