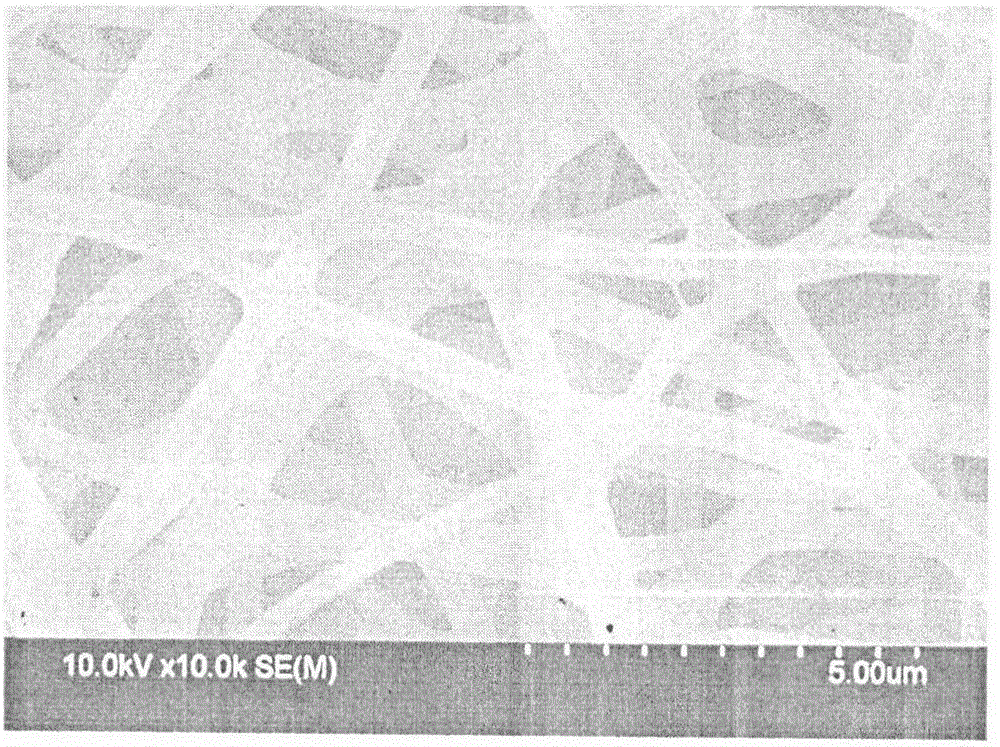

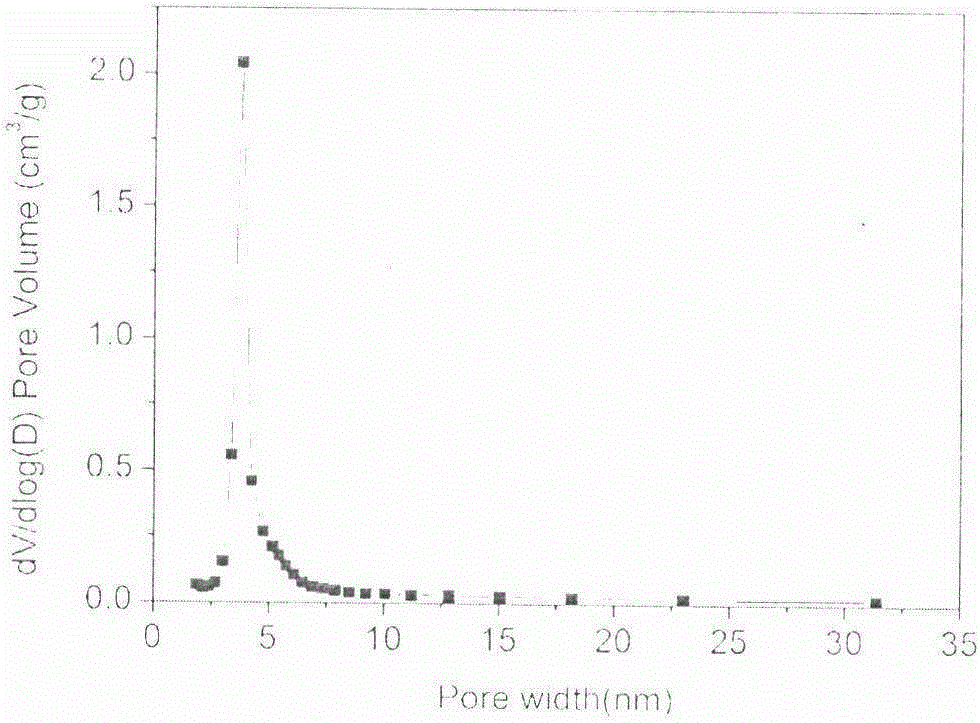

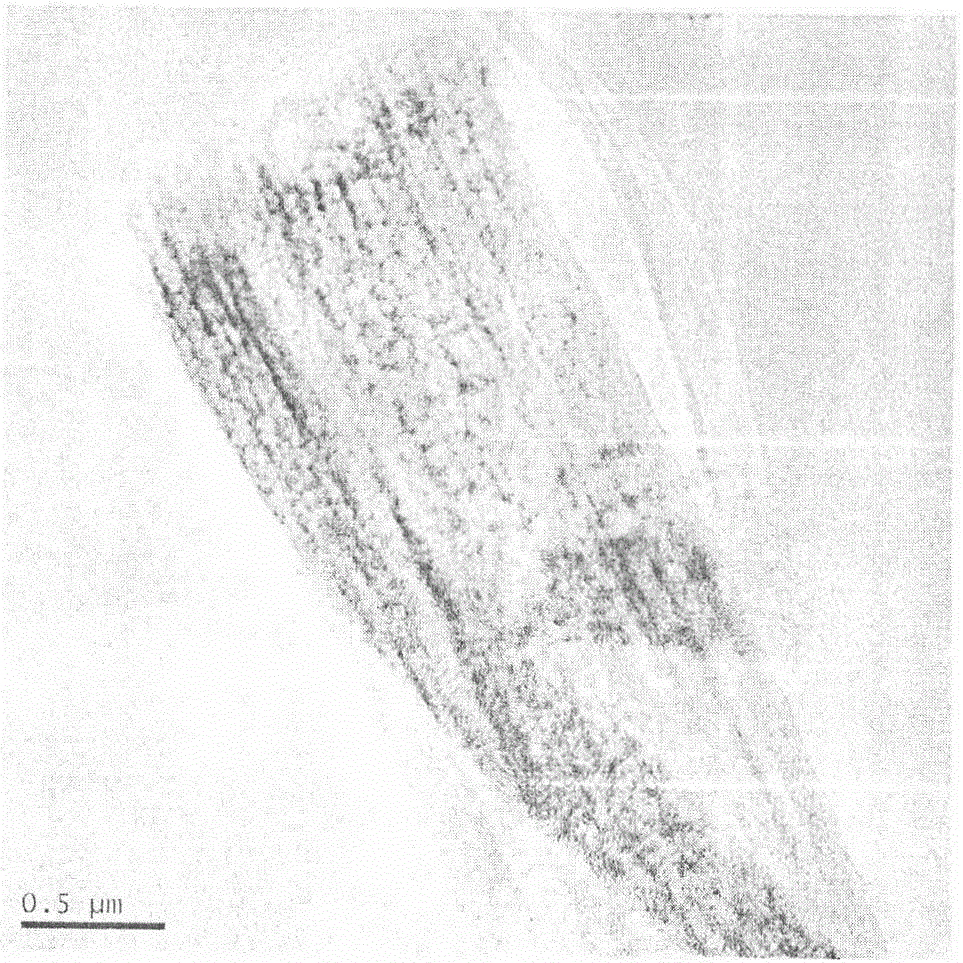

Preparation method of ordered mesoporous carbon nanofibers

A nano-carbon fiber and orderly technology, applied in the field of nano-porous carbon fiber preparation, to achieve the effects of high mesoporosity, high carbon yield, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing ordered mesoporous carbon nanofibers, comprising the following steps:

[0031] (1) Preparation of ethanol solution of phenolic resin / polyvinylpyrrolidone / triblock copolymer / inorganic salt

[0032] First dissolve the block copolymer F127 in absolute ethanol, and stir at -10°C to obtain a homogeneous solution. After 10 minutes, magnesium nitrate was added, and the mass ratio of inorganic salt to phenolic resin was 1:2. Continue stirring until completely dissolved. Then add phenolic resin ethanol solution (average molecular weight is 500), the ratio of phenolic resin and block copolymer is 1:2. Stirring was continued for 2h. Finally, polyvinylpyrrolidone was added, and the mass fraction of polyvinylpyrrolidone was 3%. After stirring for 10 h, a homogeneous solution was obtained. The mixed solution was subjected to defoaming treatment, and then sealed and stood at room temperature for 1 day to obtain a spinning solution.

[0033] (2) Preparation...

Embodiment 2

[0041] A method for preparing ordered mesoporous carbon nanofibers, comprising the following steps:

[0042] (1) Preparation of ethanol solution of phenolic resin / polyvinylpyrrolidone / triblock copolymer / inorganic salt

[0043] First dissolve the block copolymer P123 in absolute ethanol and stir at 45°C to obtain a homogeneous solution. After 10 minutes, ferric chloride was added, and the mass ratio of inorganic salt to phenolic resin was 2:1. Continue stirring until completely dissolved. Then add phenolic resin ethanol solution (average molecular weight is 1000), the ratio of phenolic resin and block copolymer is 2:3. Stirring was continued for 3h. Finally, polyvinylpyrrolidone was added, and the mass fraction of polyvinylpyrrolidone was 4%. After stirring for 13h, a homogeneous solution was obtained. The mixed solution was subjected to defoaming treatment, and then sealed and stood at room temperature for 1.5 days to obtain a spinning solution.

[0044] (2) Preparation ...

Embodiment 3

[0052] A method for preparing ordered mesoporous carbon nanofibers, comprising the following steps:

[0053] (1) Preparation of ethanol solution of phenolic resin / polyvinylpyrrolidone / triblock copolymer / inorganic salt.

[0054] First dissolve the block copolymer F127 in absolute ethanol, and stir at 50°C to obtain a uniform solution. After 10 minutes, add magnesium chloride, and the mass ratio of inorganic salt to phenolic resin is 3:1. Continue stirring until completely dissolved. Then add phenolic resin ethanol solution (average molecular weight is 1500), the ratio of phenolic resin and block copolymer is 1:2. Stirring was continued for 4h. Finally, polyvinylpyrrolidone was added, and the mass fraction of polyvinylpyrrolidone was 5%. After stirring for 16h, a homogeneous solution was obtained. The mixed solution was subjected to defoaming treatment, and then sealed and allowed to stand at room temperature for (2) days to obtain a spinning solution.

[0055] (2) Preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com