Two-step method for preparing olefin and aromatic hydrocarbon by catalyzing and upgrading bio-oil

A bio-oil and aromatic hydrocarbon technology, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, physical/chemical process catalysts, etc., can solve the problems of too fast catalyst deactivation and low yield of hydrocarbons, etc. Achieve the effect of improving stability and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) The water-phase bio-oil is continuously injected into the selective hydrogenation reactor with a high-pressure pump, and the mass space velocity is 3h -1 , a single catalyst bed is used for catalysis, Ru / C is the catalyst, hydrogen is the carrier gas, the temperature is 125°C, and the pressure is 5.2MPa. After the test, the hydrogenation liquid product is collected.

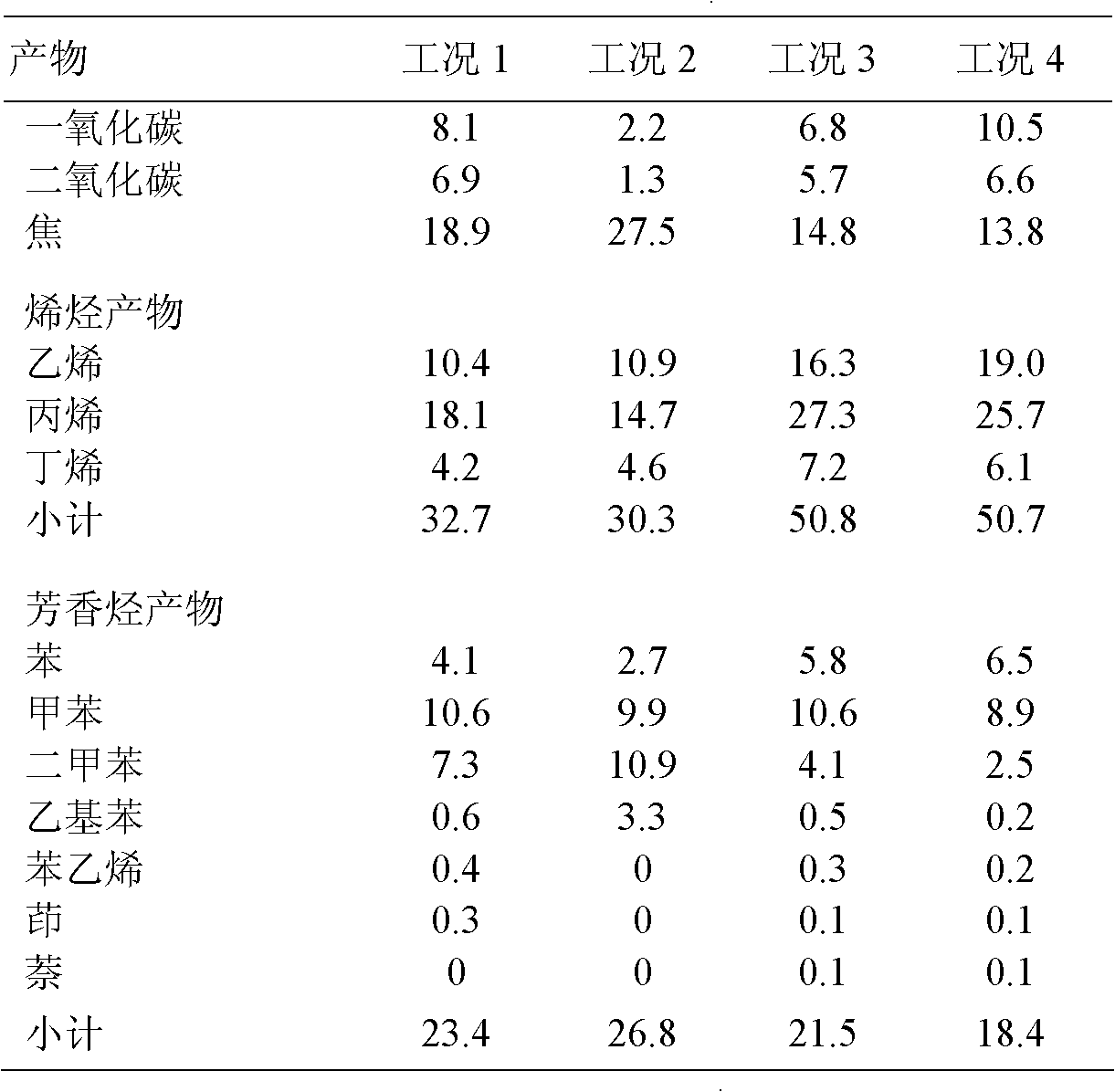

[0023] (2) The hydrogenation product is injected into the zeolite catalytic reactor with an atmospheric pump, and the mass space velocity is 11.7h -1 , HZSM-5 was used as the catalyst, helium was used as the carrier gas, and the temperature was 600 °C. The collected product was analyzed by GC / MS and GC-TCD / FID, and the carbon yield of the product is shown in Table 1 (working condition 1).

Embodiment 2

[0025] (1) The water-phase bio-oil is continuously injected into the selective hydrogenation reactor with a high-pressure pump, and the mass space velocity is 3h -1 , The catalysis adopts double catalyst bed. The water-phase bio-oil first passes through a bed composed of Ru / C catalyst, and the operating conditions of the bed are as follows: hydrogen is the carrier gas, the temperature is 125°C, and the pressure is 10MPa. Then it passes through a bed composed of Pt / C catalyst. The operating conditions of the bed are as follows: hydrogen is the carrier gas, the temperature is 250°C, and the pressure is 10MPa. After the test, the hydrogenation liquid product is collected.

[0026] (2) The hydrogenation product is injected into the zeolite catalytic reactor with an atmospheric pump, and the mass space velocity is 11.7h -1 , HZSM-5 was used as the catalyst, helium was used as the carrier gas, and the temperature was 400 °C. The collected product was analyzed by GC / MS and GC-TCD / F...

Embodiment 3

[0028] (1) The water-phase bio-oil is continuously injected into the selective hydrogenation reactor with a high-pressure pump, and the mass space velocity is 3h -1 , The catalysis adopts double catalyst bed. The water-phase bio-oil first passes through a bed composed of Ru / C catalyst, and the operating conditions of the bed are as follows: hydrogen is the carrier gas, the temperature is 125°C, and the pressure is 10MPa. Then it passes through a bed composed of Pt / C catalyst. The operating conditions of the bed are as follows: hydrogen is the carrier gas, the temperature is 250°C, and the pressure is 10MPa. After the test, the hydrogenation liquid product is collected.

[0029] (2) The hydrogenation product is injected into the zeolite catalytic reactor with an atmospheric pump, and the mass space velocity is 11.7h -1 , HZSM-5 was used as the catalyst, helium was used as the carrier gas, and the temperature was 600 °C. The collected product was analyzed by GC / MS and GC-TCD / F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com