Evaporation method and device easy for polymerizing hydrocarbon solution

A technology that is easy to polymerize and hydrocarbons, applied in the direction of evaporation, separation methods, chemical instruments and methods, etc., can solve the problems that affect the stable operation of the evaporation efficiency device, the low separation efficiency of the ethylbenzene recovery tower, and affect the long-term stable operation of the device. Achieve the effects of avoiding small evaporation capacity, strong anti-polymerization ability, low material consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

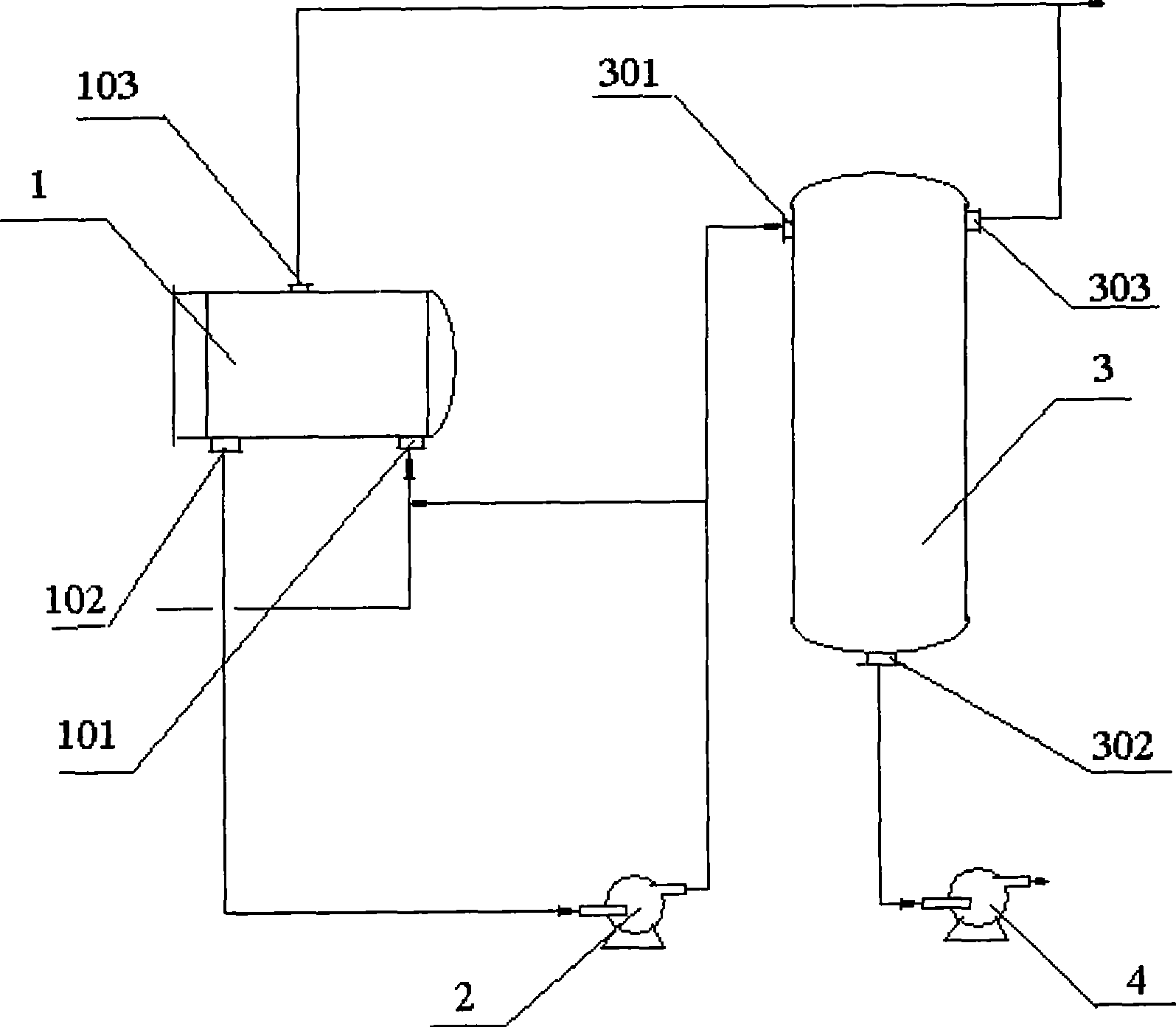

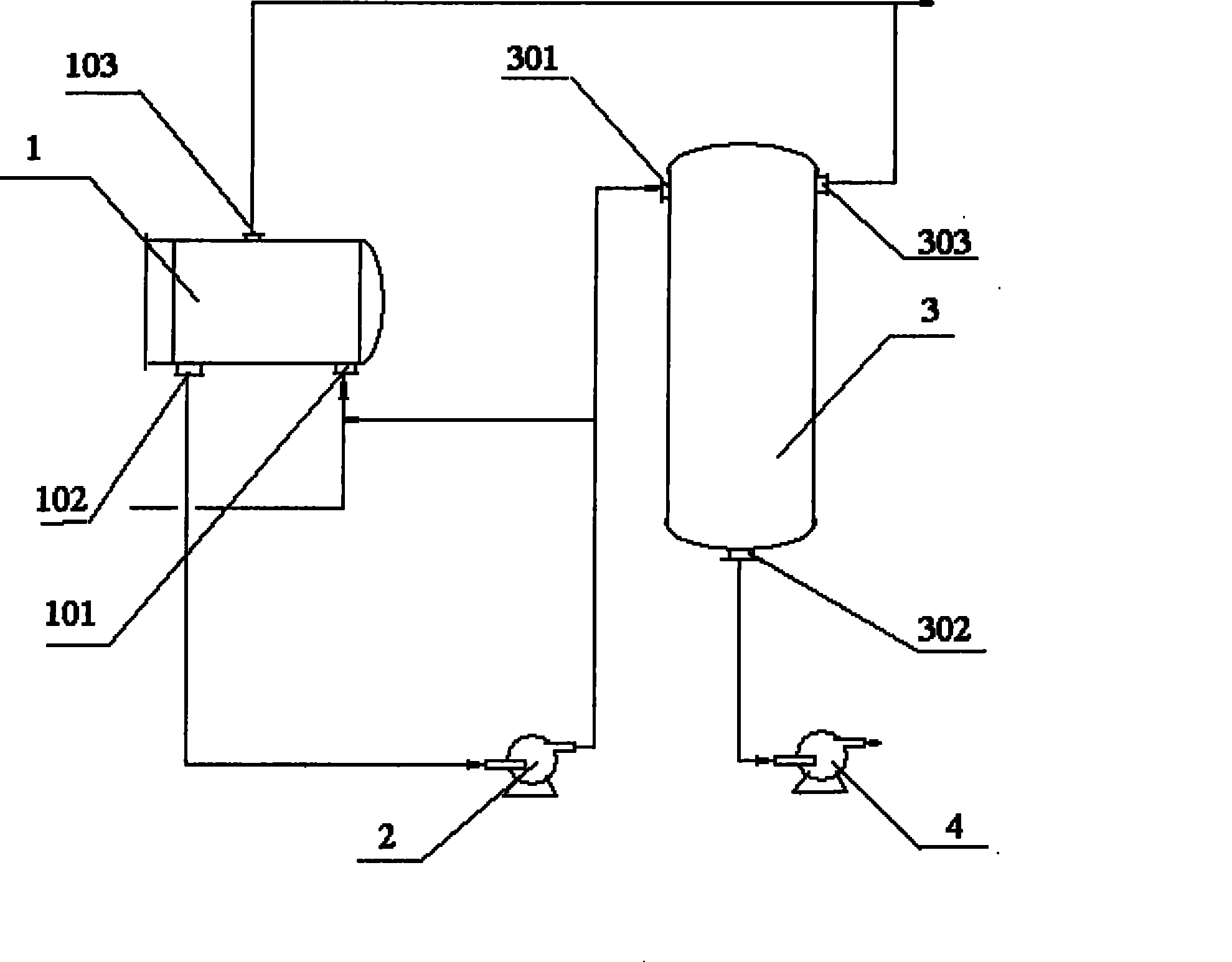

[0026] The device and process shown in Figure 1 are used.

[0027] The main evaporator 1 is a horizontal kettle evaporator, which is a general market-issued product;

[0028] Thin film evaporator 3 is selected from Wuxi Huabao Pharmaceutical Equipment Co., Ltd. as Lg-6m 2 Efficient centrifugal thin film evaporator;

[0029] Raw material: polyethylbenzene solution containing vinylethylbenzene, wherein the weight content of vinylethylbenzene is 24%;

[0030] After the above-mentioned polyethylbenzene raw material is mixed with 0.5 times by weight of water vapor, it is sent to the main evaporator 1, evaporated at 120KPa and 133°C, and the weight of the liquid phase circulated into the main evaporator 1 is the 5 times of the easily polymerizable hydrocarbon solution of device 1;

[0031] The material entering the thin-film evaporator 3 is 0.3 times the weight of the total polyethylbenzene solution feed, and evaporates at 120KPa and 133°C. During the evaporation process of the m...

Embodiment 2

[0033] The device and process shown in Figure 1 are used.

[0034] The main evaporator 1 is a falling film evaporator, which is a general market-issued product;

[0035] Thin film evaporator 3 is selected from Wuxi Huabao Pharmaceutical Equipment Co., Ltd. as Lg-20m 2 Efficient centrifugal thin film evaporator;

[0036] Raw materials: C9 and C10 cracked by Yangzi Petrochemical, wherein the weight content of methyl styrene, dicyclopentadiene, vinyl ethyl benzene, divinyl benzene, indene and other unsaturated olefins is 40%;

[0037] The above-mentioned cracking C9 and C10 are sent to the main evaporator 1, evaporated at 120KPa, 170°C, and the weight of the liquid phase circulated into the main evaporator 1 is 10% of the easily polymerizable hydrocarbon solution sent to the main evaporator 1. times;

[0038] The material entering the thin film evaporator 3 is 0.25 times the feed weight of the total C9 and C10, evaporated at 120KPa and 188°C, and about 2% of unsaturated monome...

Embodiment 3

[0040] The device and process shown in Figure 1 are used.

[0041] The main evaporator 1 is a falling film evaporator, which is a general market-issued product;

[0042] Thin film evaporator 3 is selected from Wuxi Huabao Pharmaceutical Equipment Co., Ltd. as Lg-10m 2 Efficient centrifugal thin film evaporator;

[0043] Raw materials: crude benzene from the coking plant of Baosteel Chemical Co., Ltd., wherein the weight content of isopentene, isoprene, cyclopentene, methylcyclopentene, styrene, methylstyrene and dicyclopentadiene is 5 %;

[0044] The above-mentioned crude benzene is sent into the main evaporator 1, evaporated at 120KPa and 132°C, and the weight of the liquid phase circulated into the main evaporator 1 is 3 times that of the easily polymerizable hydrocarbon solution sent into the main evaporator 1;

[0045] The material entering the thin-film evaporator 3 is 0.2 times the feed weight of the total crude benzene, evaporated at 120KPa and 138°C, and about 0.1% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com