Preparation method of filter material base activated carbon fiber

A technology of activated carbon fiber and filter material, which is applied in the field of resource reuse activated carbon to prepare adsorption materials, can solve the problems of no activated carbon fiber and other problems, and achieve the effects of environmental protection, low cost and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

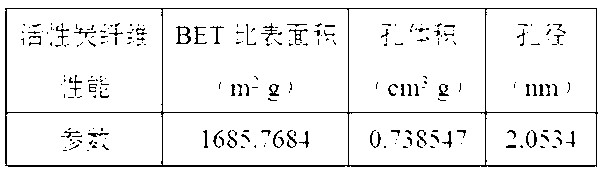

Embodiment 1

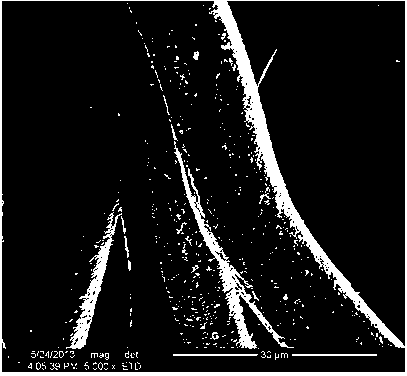

[0026] (1) Cut the waste filter material of needle felt into small pieces, and use H 2 Ultrasonic impregnation in a mixed solution of O and ethanol for 20-30 minutes, then repeatedly washed with deionized water for 3 to 4 times, and then put the cleaned filter material in a vacuum drying oven at 80-110°C for 12-24 hours;

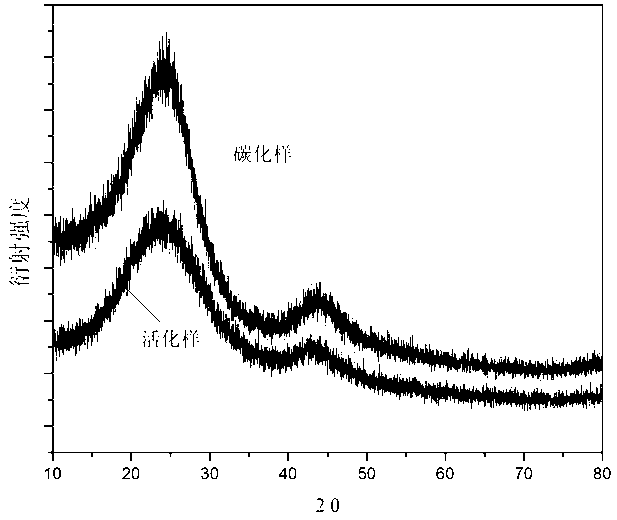

[0027] (2) Put the dried filter material in (1) in an inert gas (N 2 ) under protection, heated to 750°C at a heating rate of 10°C / min, carried out carbonization treatment for 1 h, and cooled to room temperature;

[0028] (3) Fully grind the carbonized product, sieve 80-100 mesh, and then fully mix it with KOH powder according to a certain mass ratio (1:1), and finally in an inert gas (N 2 ) at a heating rate of 10°C / min to 750°C, activated for 120 min, and cooled to room temperature;

[0029] (4) After immersing the activated product in a hydrochloric acid solution with a certain mass concentration for 12-24 h, then wash it repeatedly with deionized water...

Embodiment 2

[0033] (1) Cut the waste filter material of needle felt into small pieces, and use H 2 Ultrasonic impregnation in a mixed solution of O and ethanol for 20-30 minutes, then repeatedly washed with deionized water for 3 to 4 times, and then put the cleaned filter material in a vacuum drying oven at 80-110°C for 12-24 hours;

[0034] (2) Put the dried filter material in (1) in an inert gas (N 2 ) under protection, heated to 800°C at a heating rate of 10°C / min, carbonized for 1 h, and cooled to room temperature;

[0035] (3) Fully grind the carbonized product, sieve 80-100 mesh, and then fully mix it with KOH powder according to a certain mass ratio (1:2), and finally in an inert gas (N 2 ) at a heating rate of 10 °C / min to 800 °C, activated for 90 min, and cooled to room temperature.

[0036] (4) After immersing the activated product in a hydrochloric acid solution with a certain mass concentration for 12-24 h, then wash it repeatedly with deionized water for 3-4 times to remove...

Embodiment 3

[0038] (1) Cut the waste filter material of needle felt into small pieces, and use H 2 Ultrasonic impregnation in a mixed solution of O and ethanol for 20-30 minutes, then repeatedly washed with deionized water for 3 to 4 times, and then put the cleaned filter material in a vacuum drying oven at 80-110°C for 12-24 hours;

[0039] (2) Put the dried filter material in (1) in an inert gas (N 2 ) under protection, heated to 850°C at a heating rate of 10°C / min, carbonized for 2 h, and cooled to room temperature;

[0040] (3) Fully grind the carbonized product, sieve 80-100 mesh, and then fully mix it with KOH powder according to a certain mass ratio (1:3), and finally in an inert gas (N 2 ) at a heating rate of 10 °C / min to 850 °C, activated for 60 min, and cooled to room temperature.

[0041] (4) After immersing the activated product in a hydrochloric acid solution with a certain mass concentration for 12-24 h, then wash it repeatedly with deionized water for 3-4 times to remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com