Polymer lithium ion cell and its preparing method

A lithium-ion battery and polymer technology, applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of difficult control of polymer reaction, high requirements for equipment and operation, and increased process complexity. Achieve the effects of easy practical production, good interface stability, and low requirements for operation and environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

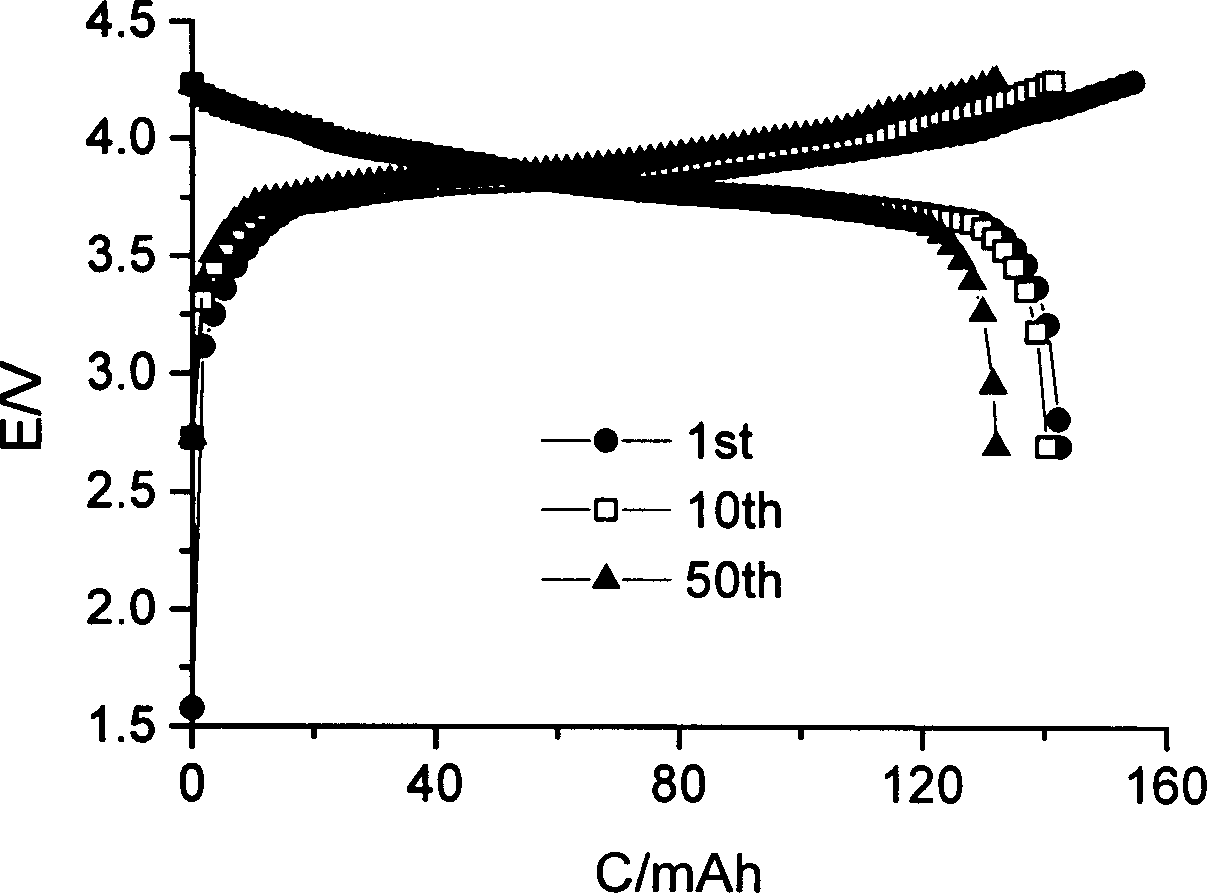

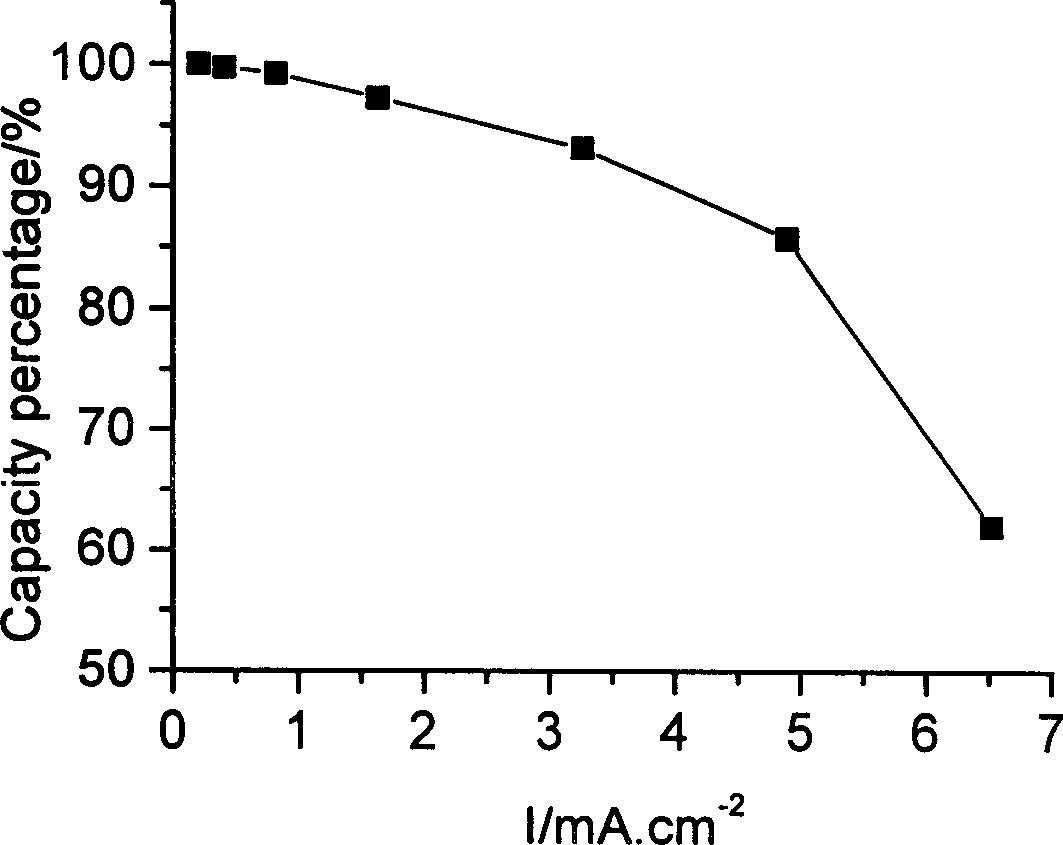

example 1:PMAML preparation approach 。0.15mol MMA、0.8mol AN and 0.05mol MALi150ml DMF( 2 ) or , 1 ,0.3g 2 ,,。50℃8hPMAML。 Synthetic proportion PMAML。PMAMLMMA、AN and MALi0.4mol、0.4mol、0.2mol and 0.1mol、0.8mol、0.1mol,100ml and 150ml,0.4g and 0.27g,60℃ and 70℃,10 and 12。 example 2:,:8.5g,1.0g(Super-P),0.5g( or SBR)。7g,,100μm。,:9.0g,(Super-P)0.3g,0.7g( or SBR)。14g,,80μm。 preparation 。 example 3:1g PMAML and 3g P(VDF-HFP)20g DMF 2 ( or NMP、、DMF 1 or ),,。 to 50μm,30min,LiPF6,EC/DMC。80%,1.4×10-3S·cm-1。 example 4: example 3 approach preparation ,PMAML and P(VDF-HFP)1g and 5g,20g DMF and 4g。, 1 (30-50℃), 1 ,。 and ,(1M LiPF6-EC/DEC,2g/500mAh)。 example 4: example 3 approach ,(30-50℃), 1 (50μm)。 and ,(1M LiPF6-EC/DMC,2g/500mAh)。 example 5: example 3 approach and , 1 (50μm)。 and ,( approach and example 3)。 pic 150,0.3C。 pic 2,0.2mA·cm-2100%。 example 6

[0019] The polymer matrix material used in the present invention is poly(methyl methacrylate-acrylonitrile-lithium methacrylate), i.e. poly(MMA-AN-MALi) (abbreviated as PMAML) and polyvinylidene fluoride or polyvinylidene fluoride (Vinylidene fluoride-hexafluoropropylene) is PVDF or P(VDF-HFP). Lithium salt is LiPF 6 、LiBF 4 , LiClO 4 , LiAsF 6 、LiCF 3 SO 3 , LiN(CF 3 SO 2 ) 2 One of. The aprotic solvent is one or more of EC (ethylene carbonate), PC (propylene carbonate), DEC (diethyl carbonate), DMC (dimethyl carbonate), DME (ethyl methyl carbonate). Example 1: The preparation method of PMAML. Dissolve 0.15mol MMA, 0.8mol AN and 0.05mol MALi with 150ml DMF (dimethylformamide) or methanol to prepare a monomer mixture, put the prepared monomer mixture into a sealable glass container, add 0.3 g of azobisisobutyronitrile initiator, and remove the oxygen in the container with dry nitrogen, and seal the reaction container. Then react at 50°C for 8h to prepare PMAML. Se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com