A lithium ion layered ternary cathode material modified by TiN and conductive polymer and a preparation method thereof

A technology of conductive polymers and cathode materials, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of limited rate performance of materials, achieve high rate performance, improve cycle stability, and improve the effect of rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

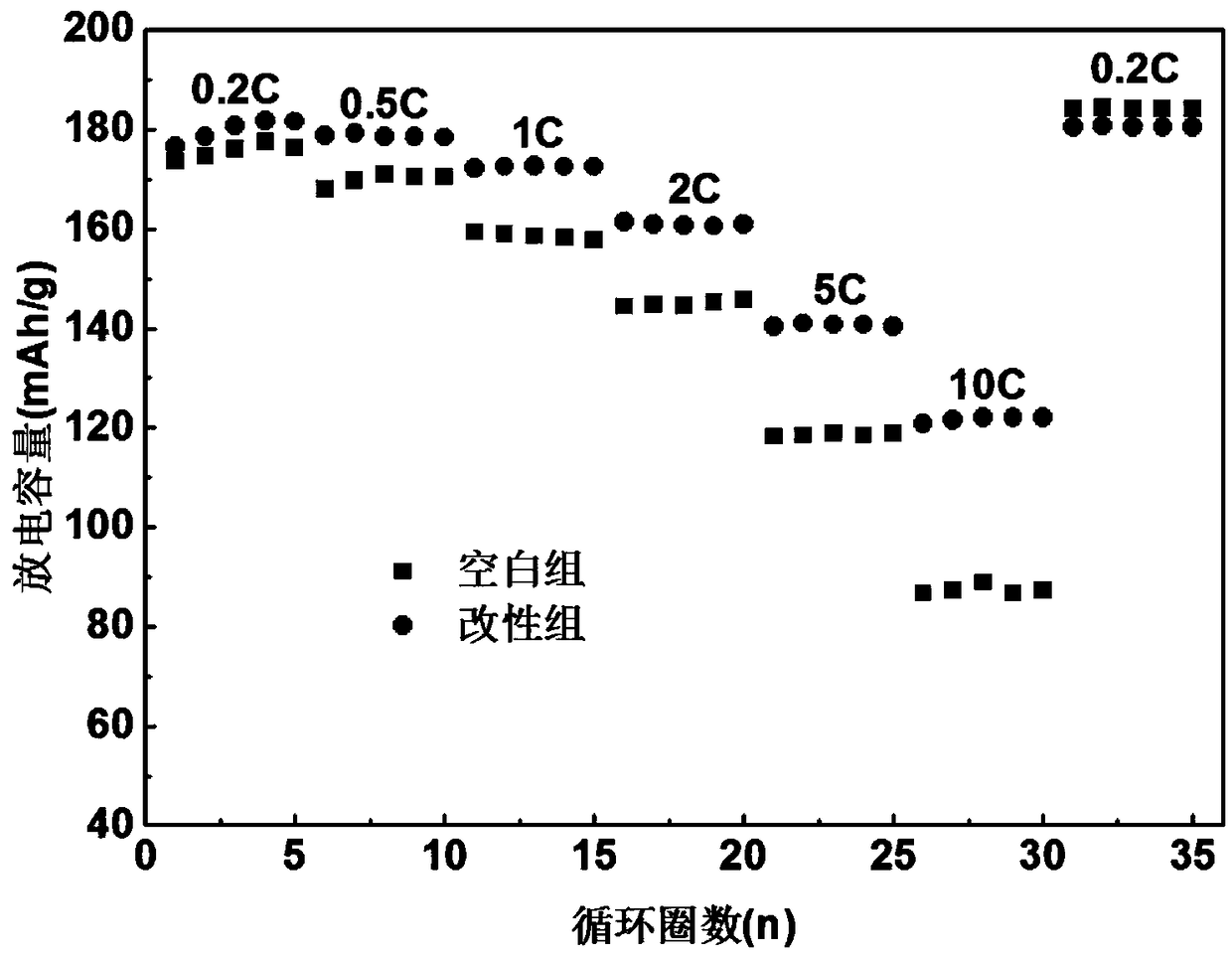

Examples

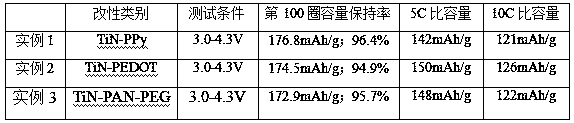

Embodiment 1

[0036] 1. Preparation of TiN and Ppy composite-coated LiNi by liquid phase adsorption and chemical oxidation polymerization 0.8 co 0.1 mn 0.1 o 2 Positive electrode material, the steps are as follows:

[0037] 0.04 g of commercially available TiN (~20 nm) nanopowder and 4 g of LiNi 0.8 co 0.1 mn 0.1 o 2Dissolve the positive electrode material in absolute ethanol, ultrasonicate the above mixed solution for 15 minutes and then continue to stir for 2 hours; then add dropwise 1.5% pyrrole monomer doped with sodium p-toluenesulfonate, methylbenzene The doping amount of sodium sulfonate is 1 / 10 of the pyrrole monomer, and then continue to stir and react for 2 hours; transfer the above solution to an environment of 0-4°C and continue to stir, and then slowly add the pre-configured FeCl 3 solution, the oxidative polymerization process lasts for 10 to 12 hours. After the reaction was completed, the obtained solid powder was sufficiently centrifuged and washed, and the obtained ...

Embodiment 2

[0047] 1. Preparation of TiN and PEDOT composite coated LiNi by liquid phase adsorption and chemical oxidation polymerization 0.8 co 0.15 al 0.05 o 2 Cathode material.

[0048] At 0 °C, 0.04 g of commercially available TiN (~20 nm) nanopowders and 4 g of LiNi 0.8 co 0.15 al 0.05 o 2 The positive electrode material was dissolved in chloroform solution, and at the same time, the O in the solution was excluded by Ar 2 , the above mixed solution was ultrasonicated for 15 minutes and then continuously stirred for 30 minutes; then 2% 3,4-ethylenedioxythiophene (EDOT) was added dropwise to the above solution and continuously stirred for 30 minutes; then, the prepared FeCl 3 The solution was added dropwise to the above mixed solution, and Ar was continuously introduced, and the reaction was continued at 0°C for 1 hour, and then reacted at 30°C for 10 hours; the reaction solution obtained was centrifuged, and then, the obtained solid was fully washed with ethanol and deionized w...

Embodiment 3

[0053] 1. Preparation of TiN and PAN-PEG composite-coated LiNi by liquid phase adsorption and chemical oxidation polymerization 0.8 co 0.1 mn 0.1 o 2 Cathode material.

[0054] At 0 °C, 0.04 g of commercially available TiN (~20 nm) nanopowders and 4 g of LiNi 0.8 co 0.1 mn 0.1 o 2 The positive electrode material was dissolved in chloroform solution, and at the same time, the O in the solution was excluded by Ar 2 , the above mixed solution was ultrasonicated for 15 minutes and then continuously stirred for 30 minutes; then, 2% aniline (An) and ethylene glycol (PEG) monomers (molar ratio 1:1) were added dropwise to the above solution and continuously stirred for 30 minutes; then, The configured ammonium persulfate ((NH 4 ) 2 S 2 o 8 ) solution was added dropwise to the above mixed solution, and N 2 Oxygen in the solution was excluded, and the reaction was continued at 0°C for 12 hours; the resulting reaction solution was centrifuged, and then the obtained solid was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com