Surface treatment method for garnet type solid electrolyte

A solid-state electrolyte and garnet-type technology, applied in electrolytes, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of impurity layer formation, achieve good dispersion, small powder particles, and increase energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

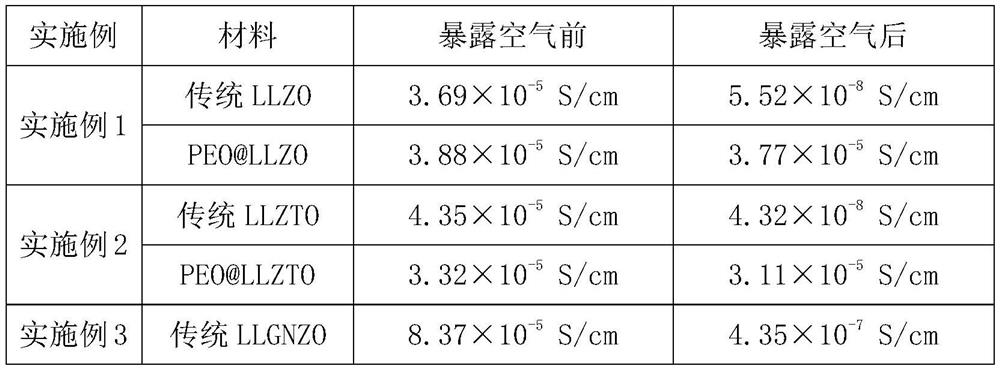

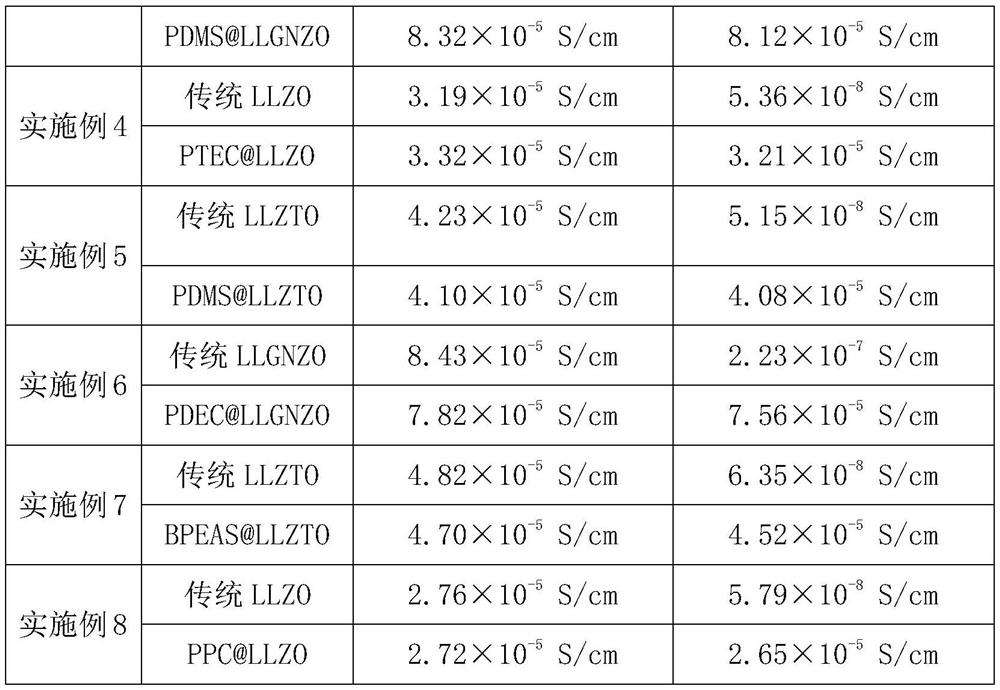

Embodiment 1

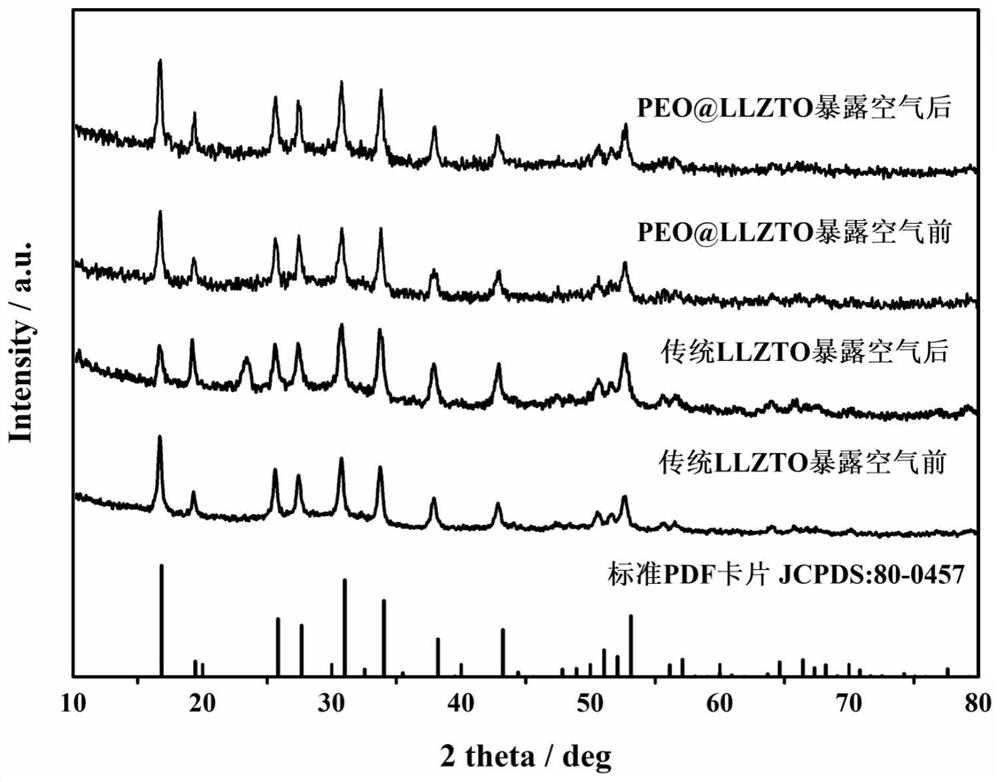

[0039] A surface treatment method of LLZO, comprising the steps:

[0040] (1) Preparation of ion-conducting polymer solution: dissolving polyoxyethylene-based polymer PEO and lithium bistrifluoromethylimide in acetonitrile, and preparing an ion-conducting polymer solution with a concentration of 1%;

[0041] (2) Pretreatment: The LLZO powder material with a particle size of 0.1 μm is treated at a high temperature of 500 °C for 2 hours in an argon atmosphere to obtain a pure LLZO powder with no impurities on the surface;

[0042] (3) Slurry preparation: Calculate and weigh the amount of pretreated LLZO powder material and ion-conducting polymer solution according to the coating thickness of 1nm, and add the pre-treated LLZO powder to the ion-conducting polymer solution In the process of ultrasonic dispersion, a uniform slurry is obtained;

[0043] (4) Finished product preparation: use a closed centrifugal spray dryer to dry the slurry, and form an ion-conducting polymer coatin...

Embodiment 2

[0046] A surface treatment method of LLZTO, comprising the steps:

[0047] (1) Preparation of ion-conducting polymer solution: dissolving polyoxyethylene-based polymer PEO and lithium bisfluorosulfonimide in acetone, and preparing an ion-conducting polymer solution with a concentration of 2%;

[0048] (2) Pretreatment: ① Treat the LLZTO powder material with a particle size of 10 μm at a high temperature of 1500 °C for 2 hours in an argon atmosphere to obtain a pure LLZTO powder with no impurities on the surface;

[0049] (3) Slurry preparation: Calculate and weigh the amount of pretreated LLZTO powder material and ion-conducting polymer solution according to the coating thickness of 50nm, and add the pre-treated LLZTO powder to the ion-conducting polymer solution In, the slurry is stirred uniformly;

[0050] (4) Finished product preparation: use a closed centrifugal spray dryer to dry the slurry, and form an ion-conductive polymer coating layer with a thickness of 50nm on the...

Embodiment 3

[0053] A surface treatment method of LLGNZO, comprising the steps:

[0054] (1) Preparation of ion-conducting polymer solution: dissolving polysiloxane-based polymer PDMS and lithium perchlorate in ethanol, and preparing an ion-conducting polymer solution with a concentration of 1.5%;

[0055] (2) Pretreatment: The LLGNZO powder material with a particle size of 1 μm is subjected to a high temperature treatment at 1000°C for 2 hours in an argon atmosphere to obtain a pure LLGNZO powder with no impurities on the surface;

[0056] (3) Slurry preparation: Calculate and weigh the amount of pretreated LLGNZO powder material and ion-conducting polymer solution according to the thickness of the coating layer of 20nm, and add the pre-treated LLGNZO powder to the ion-conducting polymer solution In the process of ball milling, a uniform slurry is obtained;

[0057] (4) Finished product preparation: Dry the slurry with a closed centrifugal spray dryer, and form an ion-conducting polymer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com