Preparation method of coated modified high-nickel ternary positive electrode material and prepared material

A cathode material and modification technology, applied in the field of prepared materials and preparation methods, can solve the problems of affecting the overall performance of the battery with interfacial stability, unable to ensure uniform and continuous coating, etc., and achieve excellent electrochemical stability and excellent elasticity. and ductility, the effect of reducing side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a coated modified high-nickel ternary positive electrode material, specifically comprising the following steps:

[0048] 1. Preparation of modified polymer emulsion

[0049] S1, the preparation steps of modified lignin amine are as follows:

[0050] Weigh lignin, diethanolamine, and deionized water at a mass ratio of 1:1.5:10, mix them evenly, and adjust the pH value to 9 with ammonia water; add formaldehyde to the above solution, heat to 60°C for 4 hours, and then add it to isopropanol A brown precipitate was obtained, and after suction filtration, it was repeatedly washed with isopropanol for 4 times, and then transferred to 60°C for 2 hours in a vacuum to obtain a modified lignin amine, which was named L-DEA; during the reaction, lignin, formaldehyde, isopropyl The mass ratio of alcohol is 1:1.5:28;

[0051] S2, the preparation steps of modified polymer emulsion are as follows:

[0052] Add trimethylolpropane-polyethylene glycol monomethyl e...

Embodiment 2

[0058] A method for preparing a coated modified high-nickel ternary positive electrode material, specifically comprising the following steps:

[0059] 1. The preparation of the modified polymer emulsion is the same as in Example 1.

[0060] 2. The preparation steps of coated modified high-nickel cathode material are as follows:

[0061] Take LiN i0.85 co 0.10 mn 0.05 o 2 The high-nickel ternary positive electrode material is added to the modified polymer emulsion, and the mass ratio of the positive electrode material to the emulsion is 5:1. It is solidified by spray drying to form a film to obtain a coated and modified high-nickel ternary positive electrode material.

[0062] Button electrical assembly, testing, and LSV testing are the same as in Example 1.

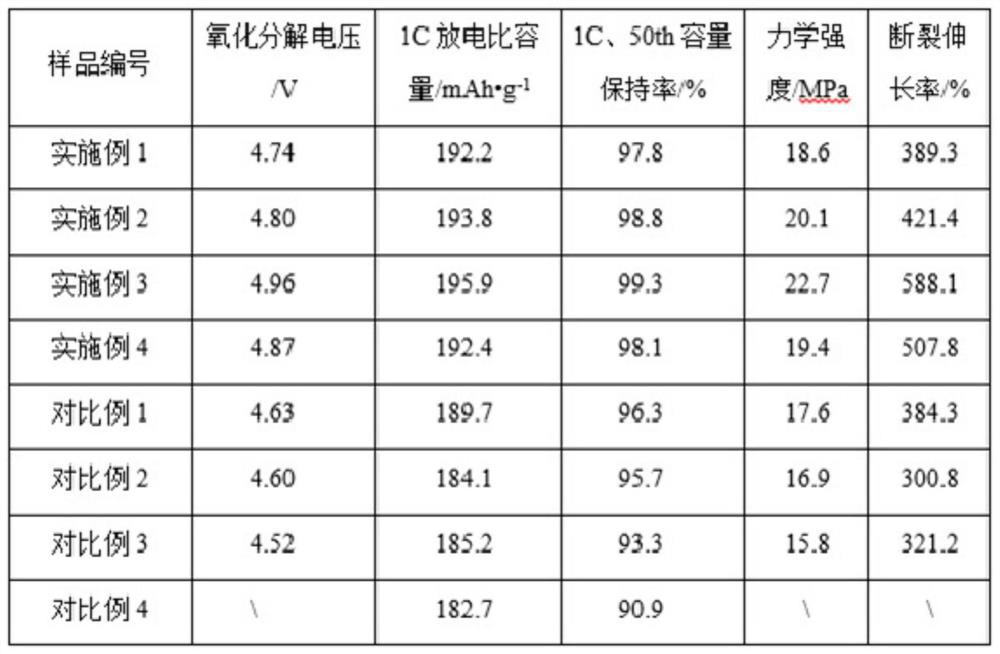

[0063] The above-mentioned positive electrode is assembled into a button battery, and the specific capacity is 193.8mAh·g when it is charged and discharged at a rate of 1C within the cut-off voltage range of 2.75-4.3...

Embodiment 3

[0065] A method for preparing a coated modified high-nickel ternary positive electrode material, specifically comprising the following steps:

[0066] 1. The preparation of the modified polymer emulsion is the same as in Example 1.

[0067] 2. The preparation steps of coated modified high-nickel cathode material are as follows:

[0068] Take LiN i0.85 co 0.10 mn 0.05 o 2 The high-nickel ternary positive electrode material is added to the modified polymer emulsion, and the mass ratio of the positive electrode material to the emulsion is 8:1. It is solidified by spray drying to form a film to obtain a coated and modified high-nickel ternary positive electrode material.

[0069] Button electrical assembly, testing, and LSV testing are the same as in Example 1.

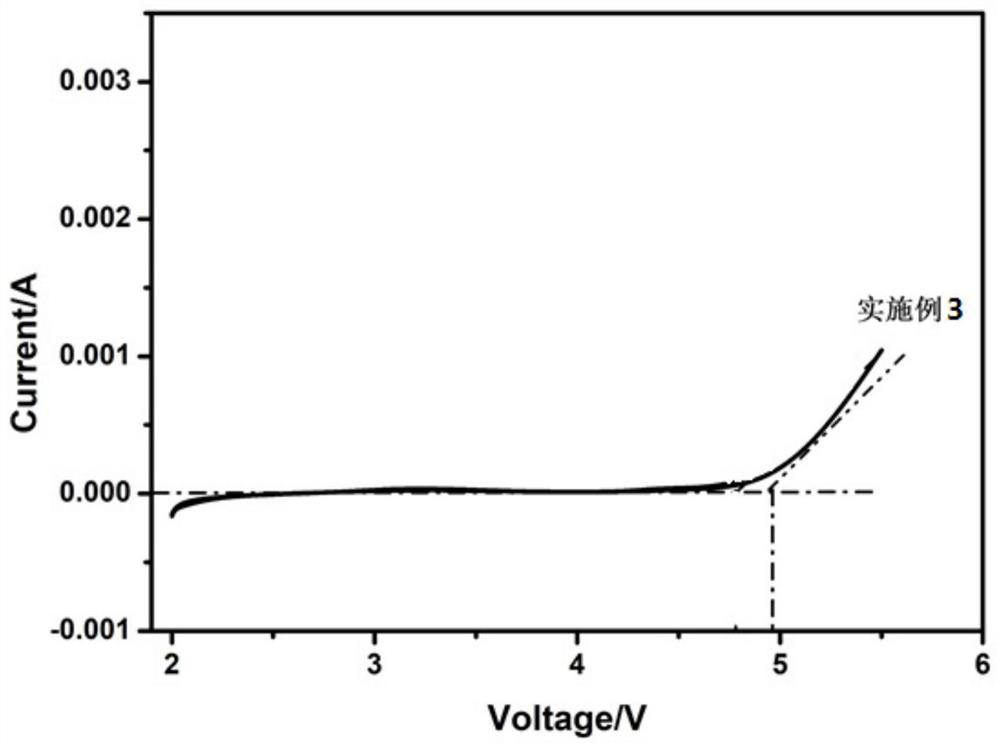

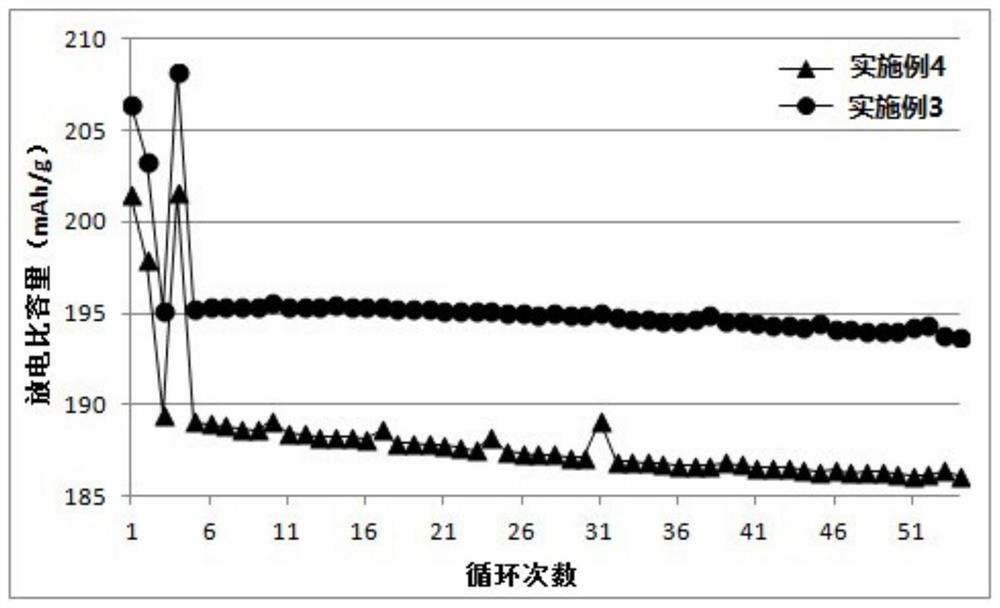

[0070] The above-mentioned positive electrode is assembled into a button battery, and the specific capacity is 195.9mAh·g when charging and discharging at a rate of 1C within the cut-off voltage range of 2.75-4.3V -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com