A kind of preparation method of strong acid and strong alkali resistant nodular cast iron pipe

A technology for ductile iron pipes and strong acid resistance, which is applied in pipeline protection, mechanical equipment, pipeline anticorrosion/rust protection, etc. Corrosion and other problems, to achieve good corrosion resistance, good protection, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Shot blasting is performed on the surface of the ductile iron pipe substrate to reach the Sa2.5 level;

[0018] (2) Spray stainless steel alloy bottom layer: purge the outer surface of the ductile iron pipe substrate with nitrogen, use 316L stainless steel wire as the two melting electrodes of the arc, and spray on the outer surface of the ductile iron pipe to form a stainless steel alloy bottom layer, the unit of the stainless steel alloy bottom layer The area weight is 130g / m 2 .

[0019] After the surface of the ductile iron pipe base is shot blasted, the stainless steel alloy bottom layer is sprayed within four hours. The diameter of the wire is 2mm. The process parameters are shown in Table 1.

[0020] Table 1 Spraying process parameters

[0021]

[0022] (3) Coating an anti-corrosion paint coating on the outer surface of the nodular cast iron pipe sprayed with a stainless steel alloy bottom layer. The layer is applied by brushing.

Embodiment 2

[0024] (1) Shot blasting is performed on the surface of the ductile iron pipe substrate to reach the Sa2.5 level.

[0025] (2) Spray stainless steel alloy bottom layer: Blow the outer surface of the ductile iron pipe base with dry and clean compressed air, use 304 stainless steel wire as the two melting electrodes of the arc, and spray on the outer surface of the ductile iron pipe to form a stainless steel alloy bottom layer, stainless steel The weight per unit area of the alloy bottom layer is 400g / m 2 .

[0026] The surface of the ductile iron pipe substrate is subjected to shot blasting treatment, and the stainless steel alloy bottom layer is sprayed within four hours. The diameter of the wire material is 4mm. The process parameters are shown in Table 2.

[0027] Table 2 Spraying process parameters

[0028]

[0029] (3) Coating an anti-corrosion paint coating on the outer surface of the nodular cast iron pipe sprayed with a stainless steel alloy bottom layer, the th...

Embodiment 3

[0031] (1) Shot blasting is performed on the surface of the ductile iron pipe substrate to reach the Sa2.5 level.

[0032] (2) Spray stainless steel alloy bottom layer: purge the outer surface of the ductile iron pipe substrate with nitrogen gas, use the nickel-based alloy stainless steel wire as the two melting electrodes of the arc, and spray on the outer surface of the ductile iron pipe to form a stainless steel alloy bottom layer, a stainless steel alloy bottom layer The weight per unit area is 200g / m 2 .

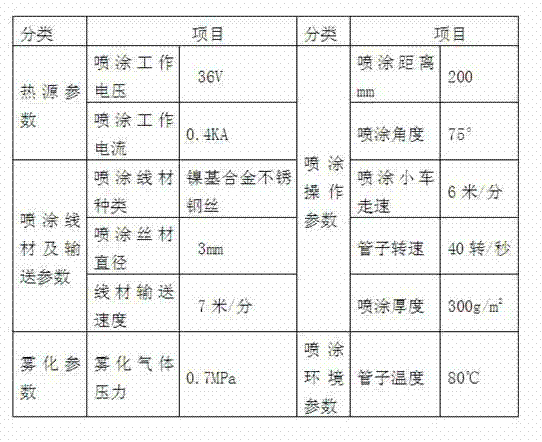

[0033] After the surface of the ductile iron pipe base is shot blasted, the stainless steel alloy bottom layer is sprayed within four hours. The diameter of the wire is 3 mm. The process parameters are shown in Table 3.

[0034] Table 3 Spraying process parameters

[0035]

[0036] (3) Coating an anti-corrosion paint coating on the outer surface of the ductile iron pipe sprayed with a stainless steel alloy bottom layer, the coating thickness is 100 microns, the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com