Magnetron sputtering cathode target for ultrahigh vacuum system

A magnetron sputtering and ultra-high vacuum technology, which is applied in sputtering coating, vacuum evaporation coating, ion implantation coating, etc., can solve the problem of restricting the electrical performance and yield of semiconductor devices and integrated circuits, and affecting the passivation film. Purity and density, sputtering equipment instability and other issues, to achieve the effect of isolating direct contact, easy maintenance and replacement, and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

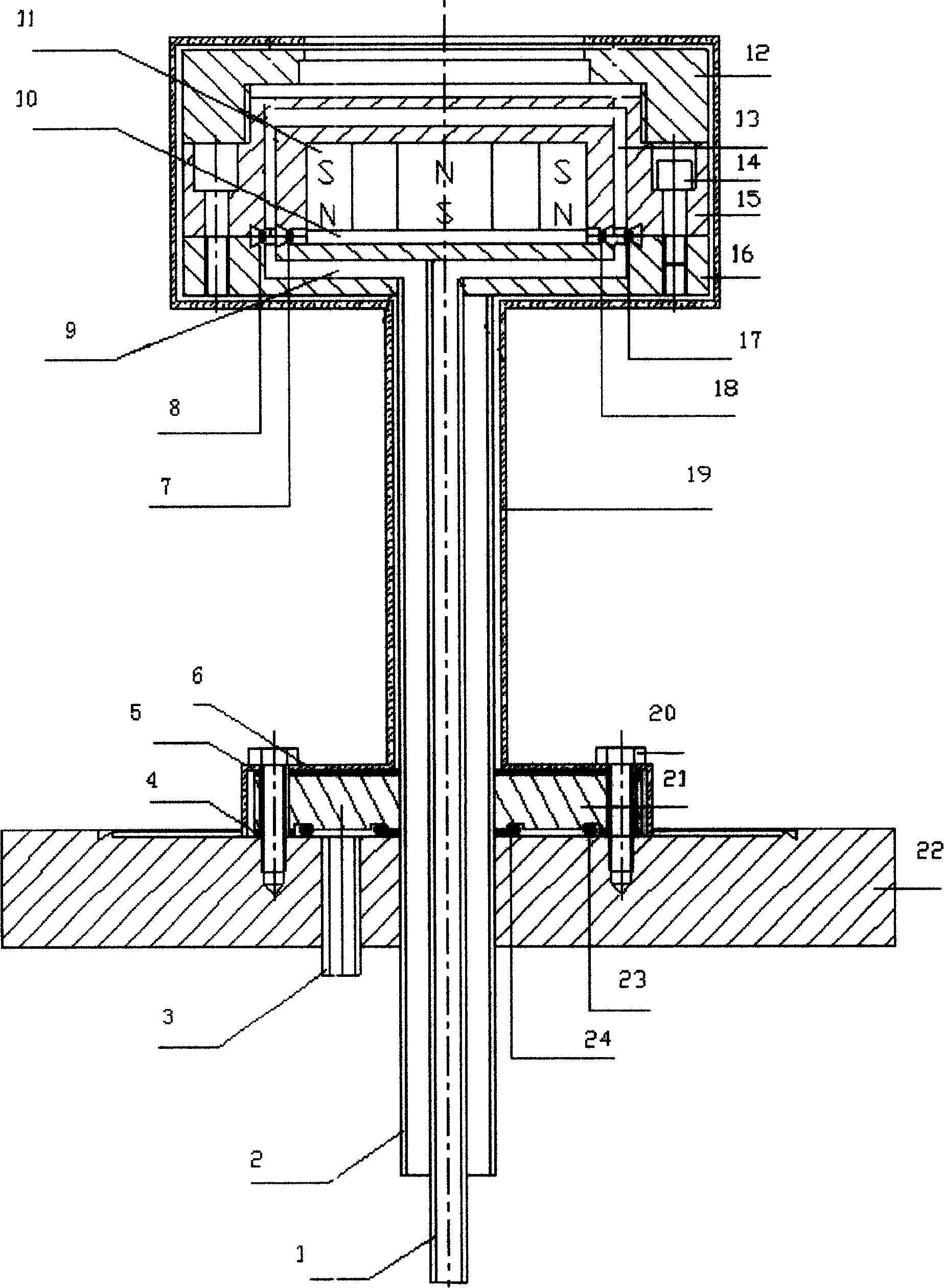

[0010] see figure 1 , the water-cooling component is composed of the covered winding cooling water tank 13 built in the connected upper flange 15, the cooling water tank 9 built in the lower flange 16, the water inlet pipe 1 and the water outlet pipe 2; wherein, the water inlet pipe 1 is set in the outlet pipe 2, and the cooling water tank 9 is cut off and welded and communicated with it, and the outlet pipe 2 is welded and communicated with the remainder of the cooling water tank 9. The cavity of the upper flange 15 is provided with a magnet holder 10 made of soft iron and a magnet 11 located on it, the upper end and the target mounting cover 12 are screwed together through their mutual threads, the lower end surface and the lower flange 16 is interposed with two metal sealing rings (17,18), and is fixedly connected through screw 14 phases. Two metal sealing rings (17, 18) are oxygen-free copper sealing rings, which are respectively located at the inner layer knife edge 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com