Design and preparation of coagulation time controllable high performance polycarboxylic acid water reducing agent

A technology of coagulation time and water reducing agent, which is applied in the design and preparation of polycarboxylate high-performance water reducing agent, can solve the problems of difficult control of water reducing agent quality, unstable polymerization, and influence of polymerization, so as to avoid difficult quality The effect of simple and environmentally friendly control and process operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

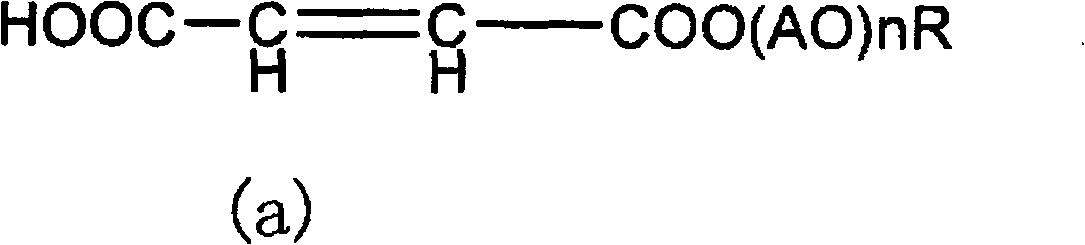

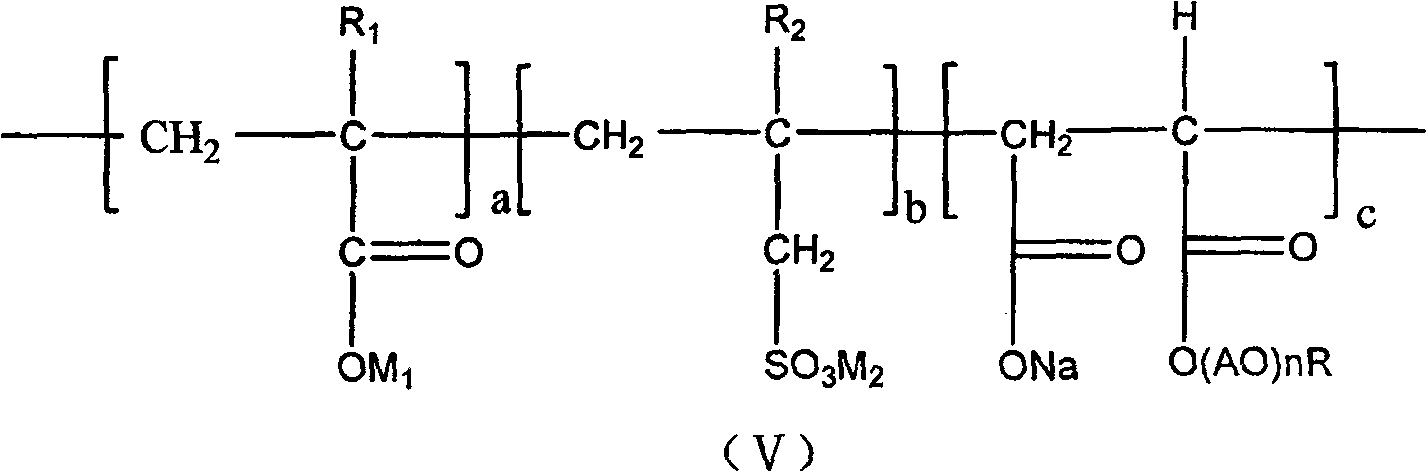

[0084] Embodiment one: in the four-neck flask that thermometer, stirring, reflux device are arranged, add 1000g (1.0mol) polyethylene glycol monomethyl ether (molecular weight is 1000), the maleic anhydride of 98g (1.0mol), 3.294g ( 0.3%, total weight ratio) of p-toluenesulfonic acid, feed nitrogen, slowly heat up to 80-90°C, and keep warm for about 5 hours to obtain a light yellow transparent liquid. Monomer (a) is obtained.

[0085] In a four-necked flask equipped with a thermometer, agitator and reflux device, add 400g of water, 480g of monomer (a), 90g of methacrylic acid, and 30g of sodium methacrylic acid sulfonate. % ammonium persulfate solution 40g, the time is controlled at 1 hour. Then keep it at 90°C for 2 hours, cool down to 30°C, add 130g of 30% NaOH solution to neutralize to Ph=7. Measure the solid content, add water, and adjust the solid content to (25±1)%. It is called polycarboxylate superplasticizer SP-1 with a molecular weight of 38,000.

[0086] Test: A...

Embodiment 2

[0089] Embodiment two: in the four-neck flask that thermometer, stirring, reflux device are arranged, add 1200g (1.0mol) polyethylene glycol monomethyl ether (molecular weight is 1200), the maleic anhydride of 98g (1.0mol), 3.894g ( 0.3%, total weight ratio) of p-toluenesulfonic acid, feed nitrogen, slowly heat up to 80-90°C, and keep warm for about 5 hours to obtain a light yellow transparent liquid. Monomer (a) is obtained.

[0090] In a four-necked flask equipped with a thermometer, agitator and reflux device, add 400g of water, 480g of monomer (a), 90g of methacrylic acid, and 30g of sodium methacrylic acid sulfonate. % ammonium persulfate solution 40g, the time is controlled at 1 hour. Then keep it at 90°C for 2 hours, cool down to 30°C, add 130g of 30% NaOH solution to neutralize to Ph=7. Measure the solid content, add water, and adjust the solid content to (25±1)%. It is called polycarboxylate superplasticizer SP-2, and its molecular weight is 41,000.

[0091] Test:...

Embodiment 3

[0094] Embodiment three: in the four-neck flask that thermometer, stirring, reflux device are arranged, add 2000g (1.0mol) polyethylene glycol monomethyl ether (molecular weight is 2000), the maleic anhydride of 98g (1.0mol), 6.294g ( 0.3%, total weight ratio) of p-toluenesulfonic acid, feed nitrogen, slowly heat up to 80-90°C, and keep warm for about 5 hours to obtain a light yellow transparent liquid. Monomer (a) is obtained.

[0095] In a four-necked flask equipped with a thermometer, agitator and reflux device, add 400g of water, 480g of monomer (a), 90g of methacrylic acid, and 30g of sodium methacrylic acid sulfonate. % ammonium persulfate solution 40g, the time is controlled at 1 hour. Then keep it at 90°C for 2 hours, cool down to 30°C, add 130g of 30% NaOH solution to neutralize to Ph=7. Measure the solid content, add water, and adjust the solid content to (25±1)%. It is called polycarboxylate superplasticizer SP-3 with a molecular weight of 44,000.

[0096] Test:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com