Hoisting construction method for fabricated overall framework cast-in-situ core tube structures

A technology of overall frame and construction method, which is applied in cranes, transportation and packaging, building construction, etc., can solve problems that limit the efficiency of tower cranes, such as the balance of hoisting work areas, and achieve the effect of high efficiency and high balance of tower cranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

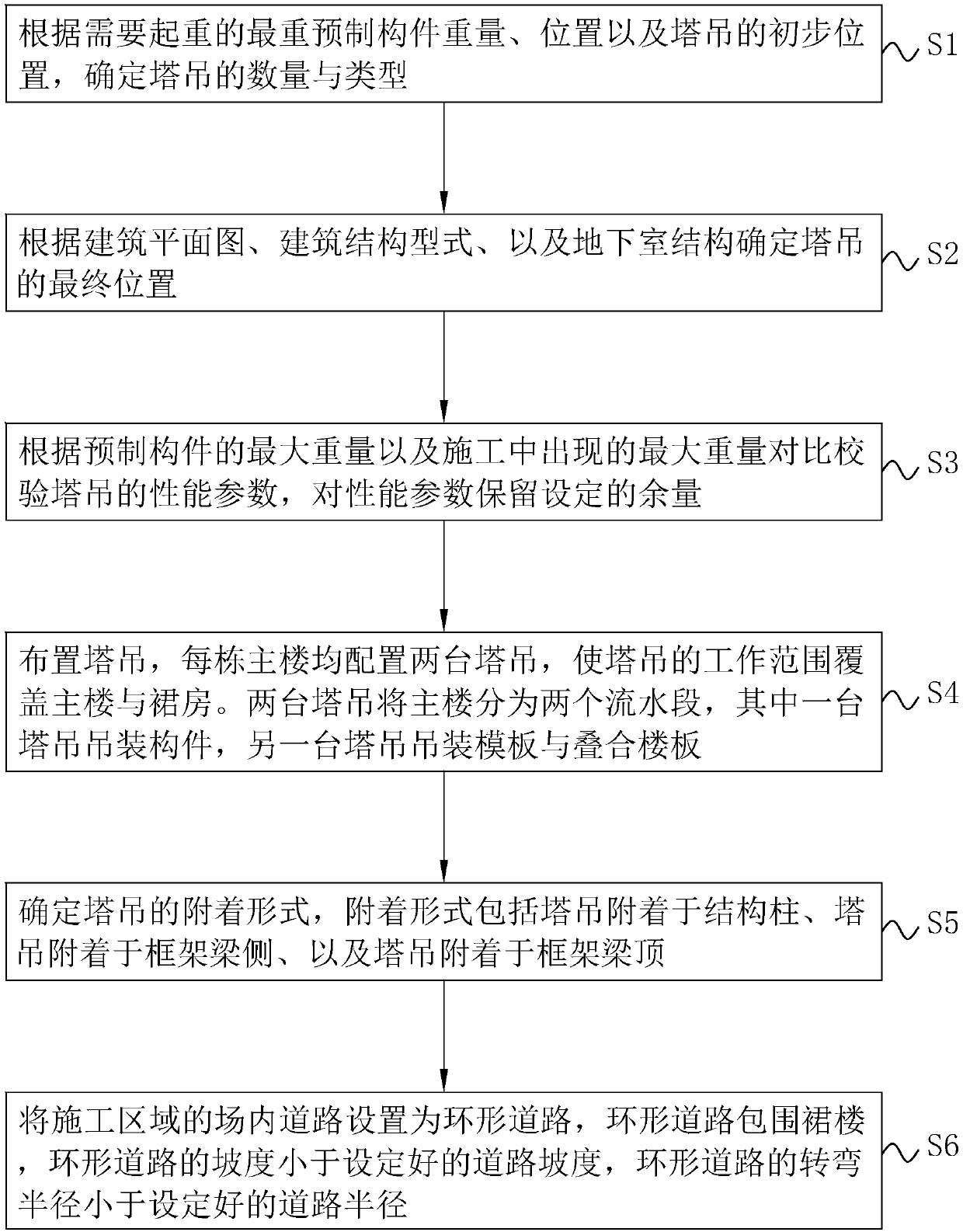

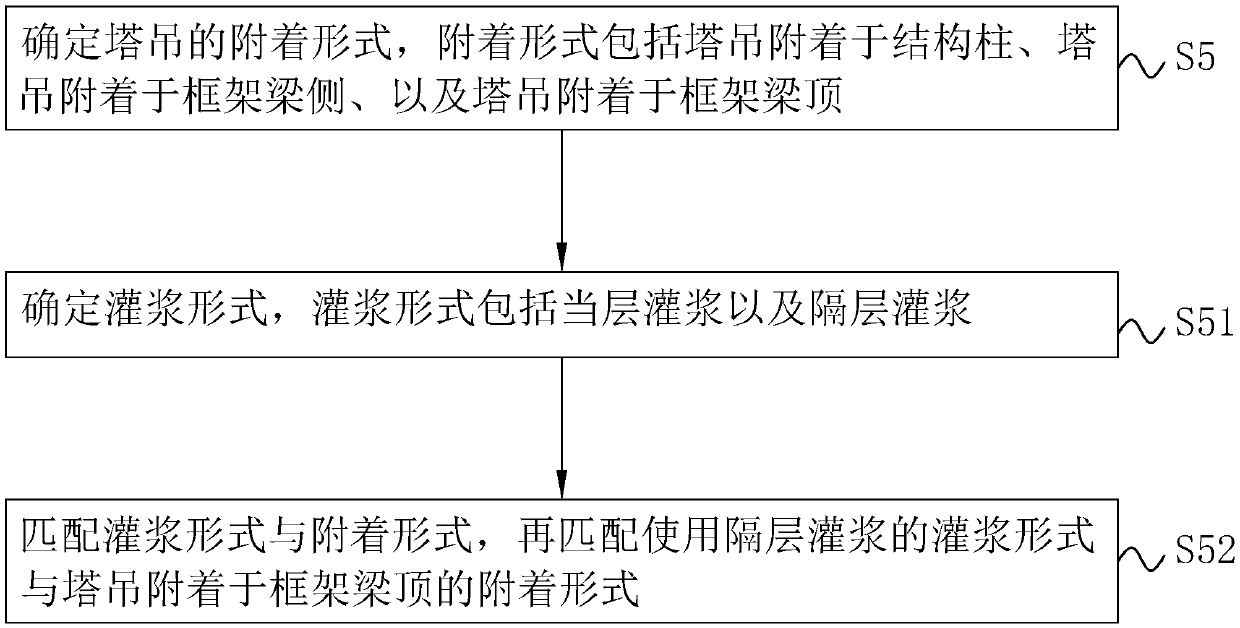

[0040] A hoisting construction method for an assembled integral frame cast-in-place core tube structure, such as figure 1 shown, including the following steps:

[0041] Step S1: Determine the number and type of tower cranes according to the weight and location of the heaviest prefabricated component to be lifted and the preliminary location of the tower cranes;

[0042] Step S2: Determine the final position of the tower crane according to the building plan, building structure type, and basement structure;

[0043] Step S3: compare and verify the performance parameters of the tower crane according to the maximum weight of the prefabricated components and the maximum weight during construction, and reserve the set margin for the performance parameters;

[0044] Step S4: Arrange tower cranes. Each main building is equipped with two tower cranes, so that the working range of the tower cranes covers the main building and the podium. Step S4 also includes: two tower cranes divide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com