Repair method of unqualified post-grouting bored concrete pile

A technology of cast-in-situ pile and post-grouting, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of affecting the construction period and loss of economic benefits, so as to achieve no influence on the construction period, simple operation, safe and reliable project quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

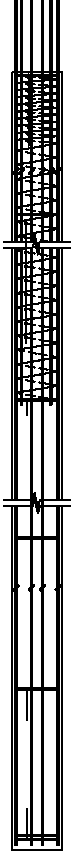

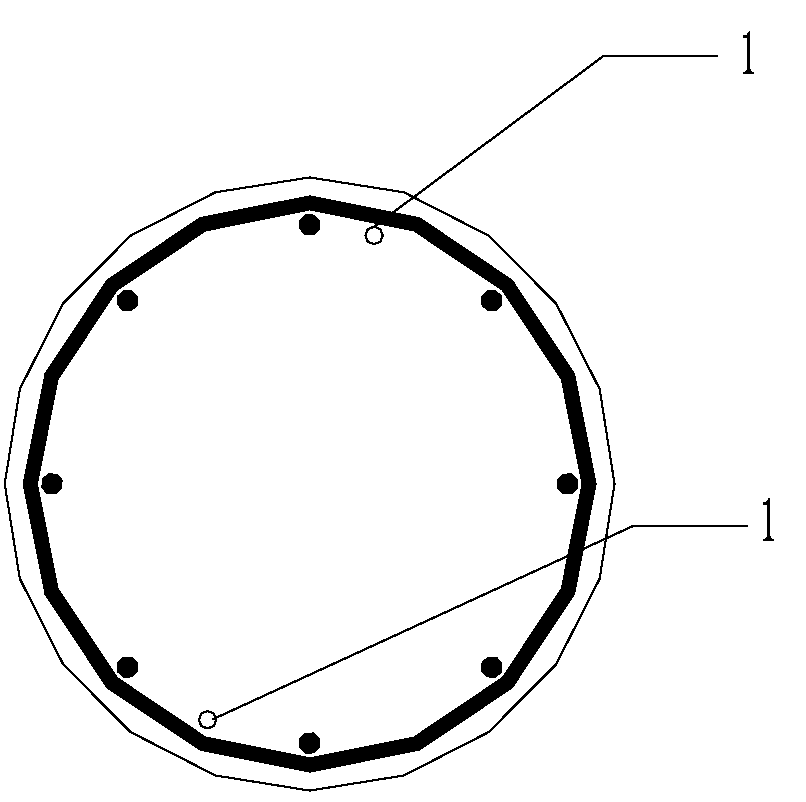

[0046] Drill two pilot holes on the outside of the cast-in-situ pile body, and set up two post-grouting pipes for construction

[0047] The method for repairing the cast-in-situ grouting pile after failing to meet the standard of the present invention is characterized in that it comprises the following steps:

[0048] a. Drill some guide holes on the outside of the cast-in-place pile body

[0049] Schematic diagram of the grouting pipe layout on the outside of the cast-in-place pile; the pilot hole, the diameter of the pilot hole is 150mm, so that the edge of the pile body reaches 300mm from the center of the pilot hole.

[0050] b. Supplementary grouting pipes on the outside of the pile, including the following steps:

[0051] (1) Investigate and analyze that the grouting pipe buried inside the original pile body can continue to be grouted;

[0052] (2) Set two pilot holes symmetrically around the outside of the cast-in-place pile body, and set a post-grouting pipe in the m...

Embodiment 2

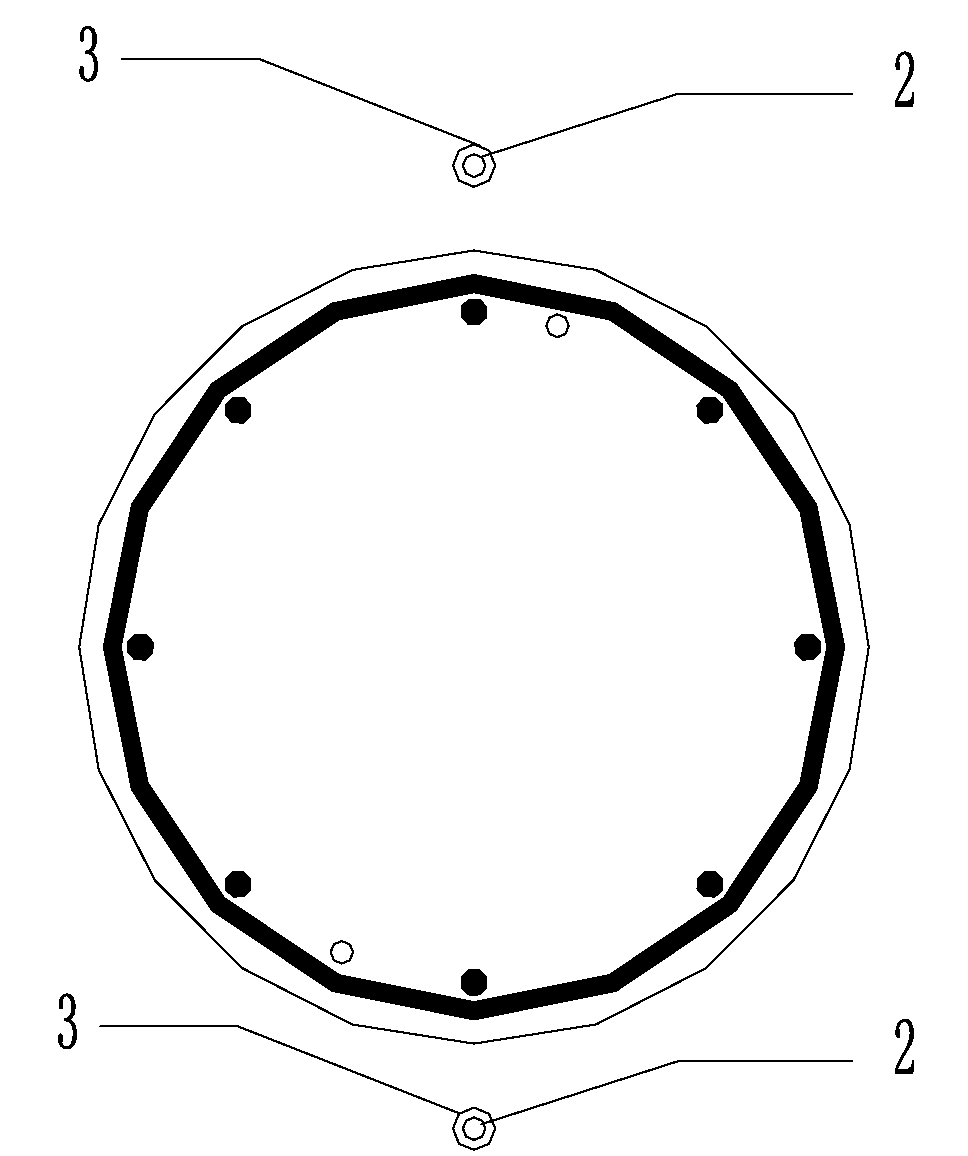

[0071] Drill four guide holes on the outside of the cast-in-situ pile body, and set up four post-grouting pipes for construction

[0072] The grouting pipe buried inside the original pile body can no longer be grouted. Four guide holes are symmetrically arranged outside the pile body of the cast-in-place pile, and a rear grouting pipe is arranged in the middle of the guide hole so that the depth of the rear grouting pipe is the same as that buried inside the original pile body. The grouting pipe is the same. The remaining steps of this embodiment are the same as in Embodiment 1.

[0073] The method for repairing cast-in-situ piles after grouting that fails to meet the standard of the present invention effectively solves the problem of how to deal with the situation that the grouting after the piles fails to meet the design requirements. Pile filling can not only guarantee the construction period, but also meet the economic benefits, and at the same time ensure the smooth impl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com