Pull rivet nut installation method capable of improving rotation-resistant capacity

A technology of blind rivet nuts and installation methods, which is applied in the field of blind rivet nuts, can solve the problems of easy rotation of round blind rivet nuts, difficulty in hexagonal holes, and easy failure of impact loads, etc., so as to improve the anti-rotation ability and processing method Variety, effect of improving seismic performance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

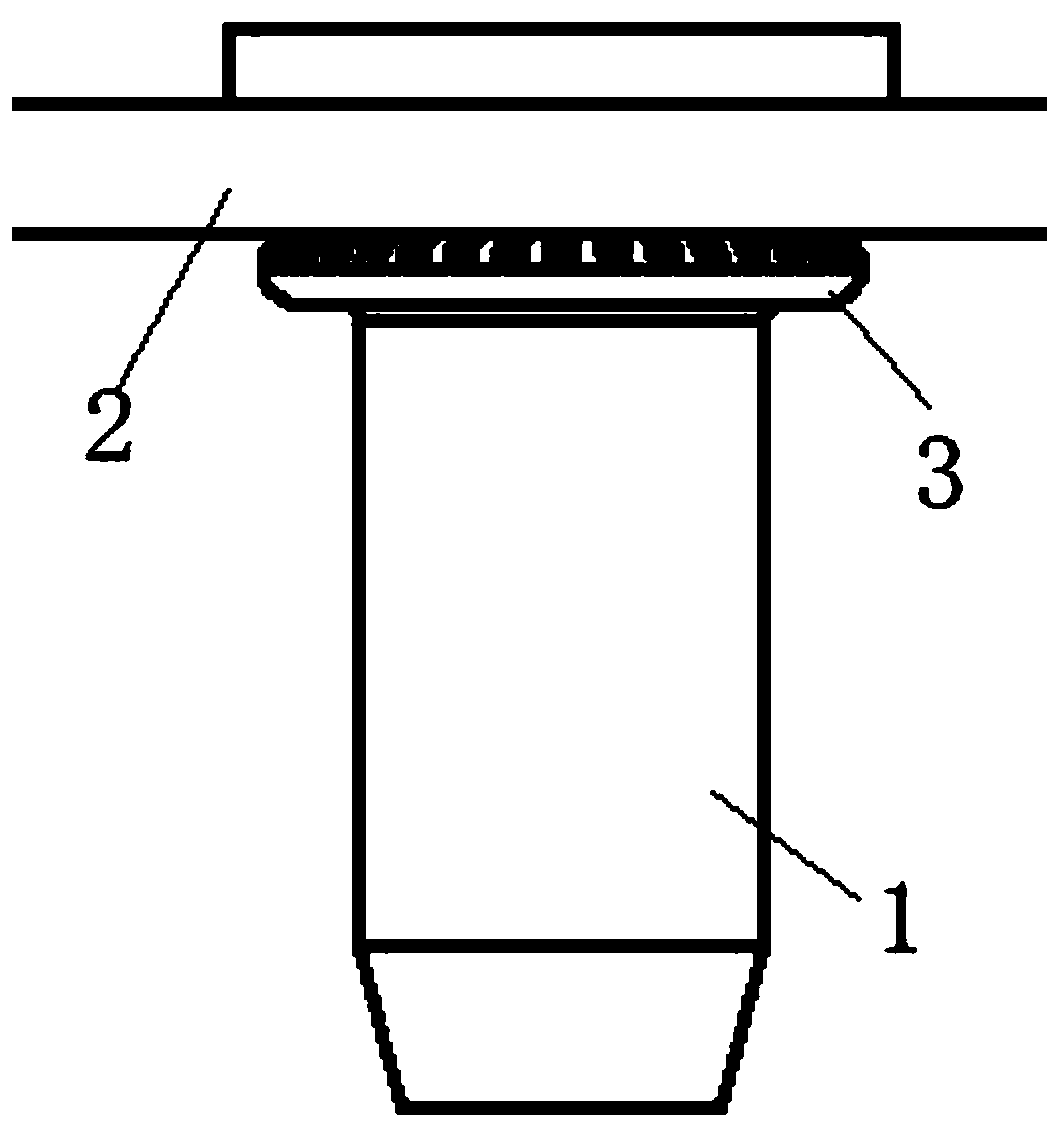

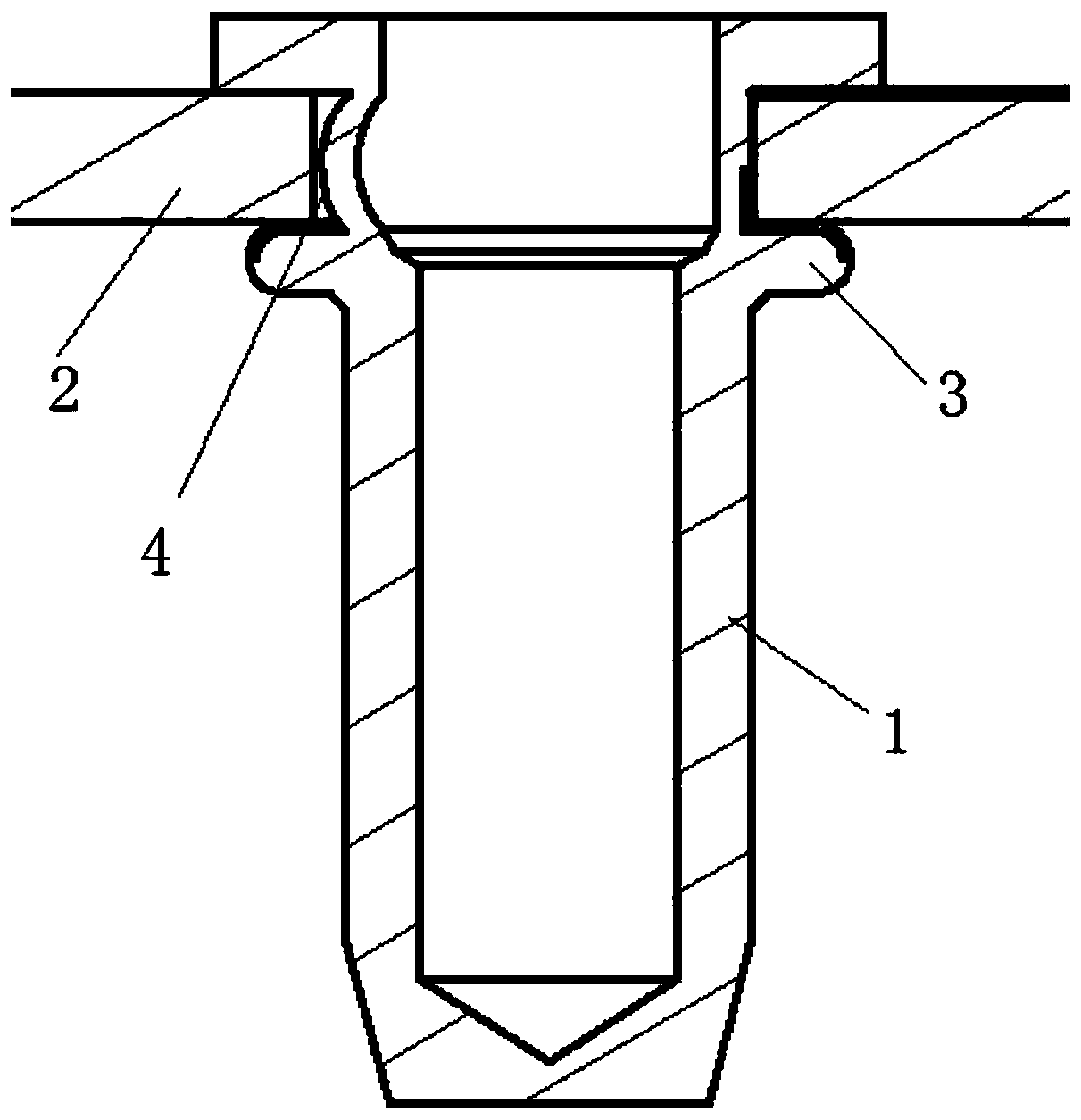

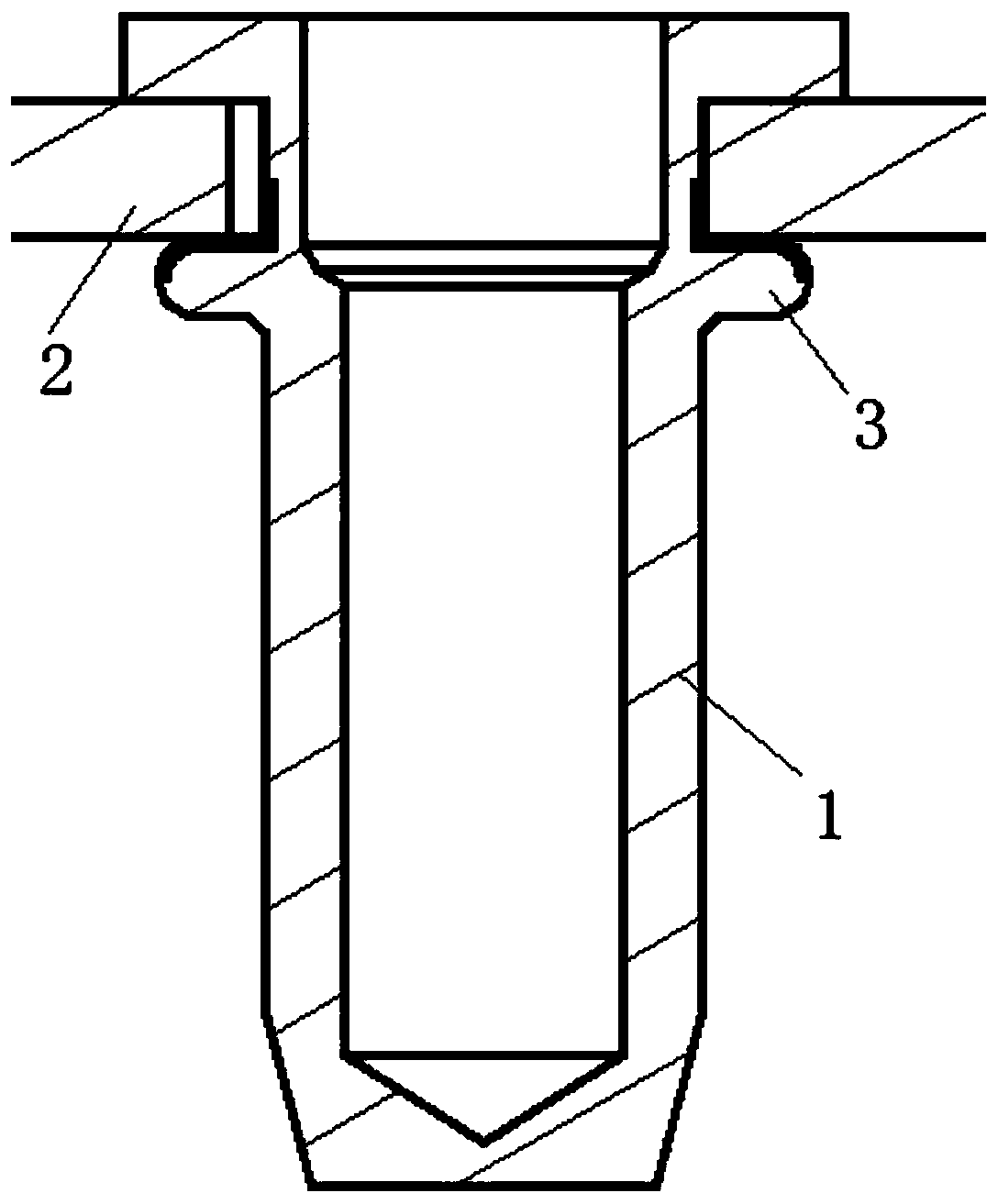

[0029] Such as figure 1 , 2 A kind of installation method that improves anti-rotation ability blind rivet nut shown in 4, comprises the following steps:

[0030] A. Open a circular installation hole 5 on the plate 2 to be installed with the blind rivet nut 1, and open a rounded gap 4 at the edge of the installation hole 5, and the radius of the rounded gap 4 is 1mm;

[0031] B. Insert the rivet gun into the inner cavity of the rivet nut 1, the rivet gun is threaded with the rivet nut 1, and the rivet gun drives the rivet nut 1 to penetrate into the installation hole 5;

[0032] C. The rivet gun pulls the rivet nut 1 to the side away from the plate 2, so that the rivet nut 1 deforms and forms a protrusion 3 on the end surface of the plate 2, and the protrusion 3 is close to the end surface of the plate and close to the position of the fillet gap 4 Expand outward, so that the contact surface between the rivet nut 1 and the plate 2 is no longer a complete cylindrical surface, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com