High-performance damping beam column mortise and tenon joint structure and manufacturing method thereof

A high-performance, damping mechanism technology, applied in the direction of building components, building structures, building types, etc., can solve the problems of instability damage, large space occupied, etc., to improve brittle damage, simple structure, and avoid damage to the damper Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

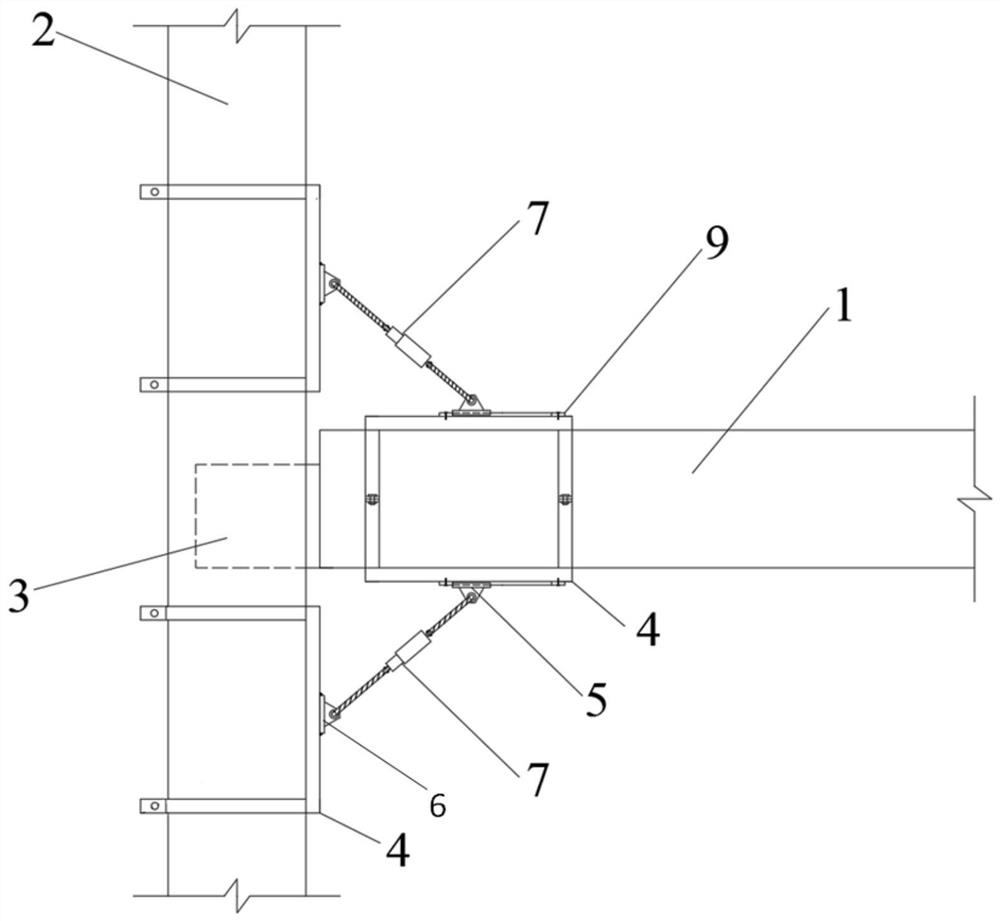

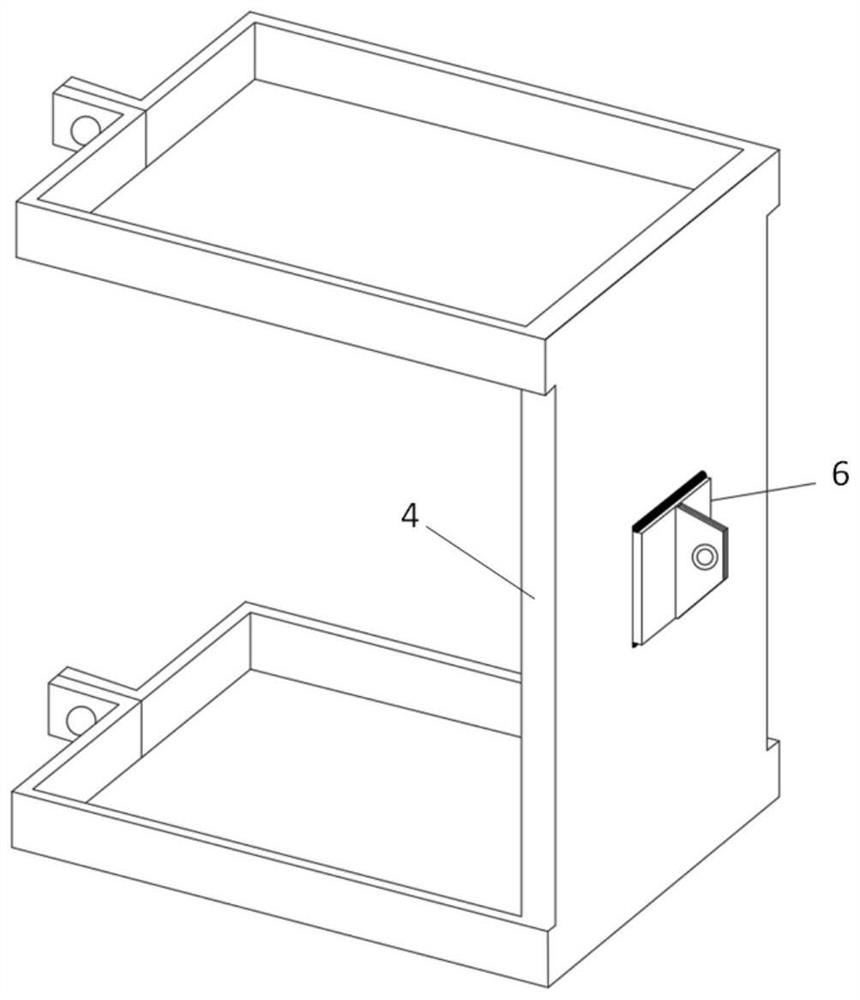

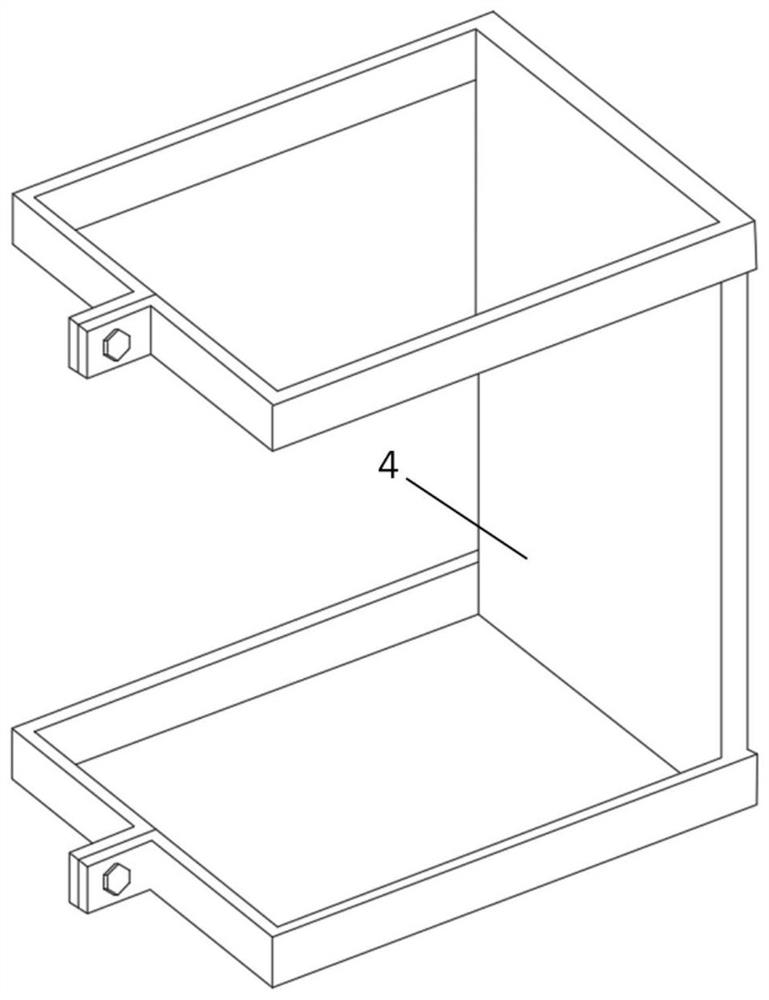

[0042] A high-performance damping beam-column mortise and tenon structure, such as figure 1 , the structure includes a wooden beam 1 and a wooden column 2 connected by tenon and tenon, and also includes a damping mechanism; the wooden beam 1 is provided with two slidable hinged supports 5, and the wooden column 2 is provided with two fixed hinged supports 6; One end of the damping mechanism is hinged with the slidable hinged support 5 , and the other end is hinged with the fixed hinged support 6 . The cross-sectional shape of the wooden beam 1 and the wooden column 2 is rectangular, and the wooden column 2 is provided with a mortise, and the wooden beam 1 is provided with a mortise, and the two are connected to the mortise and tenon joint 3 .

[0043] This structure greatly improves the pull-out resistance and rotation resistance of the beam-column mortise and tenon joints. The slidable hinged support 5 can effectively avoid the disadvantage of the damping mechanism being pron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com