Replaceable pre-embedded anchoring channel and mounting method thereof

A channel and anchoring technology, which is applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of inestimable steel corrosion and large area, and achieve the effect of meeting the needs of structural design, reducing impact, and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

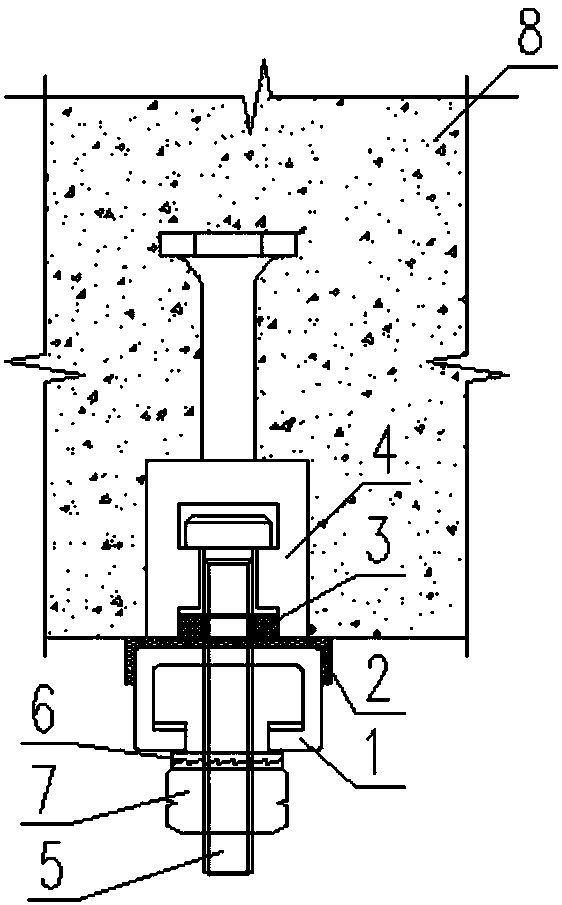

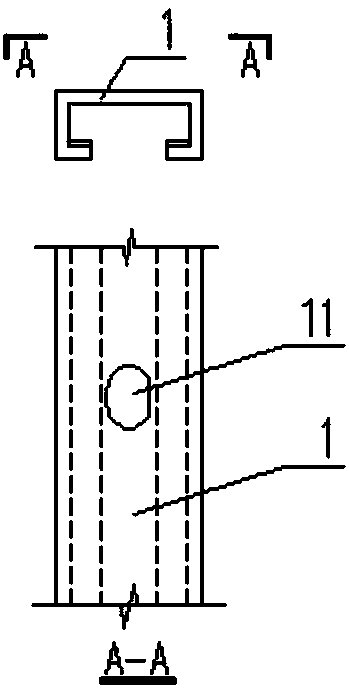

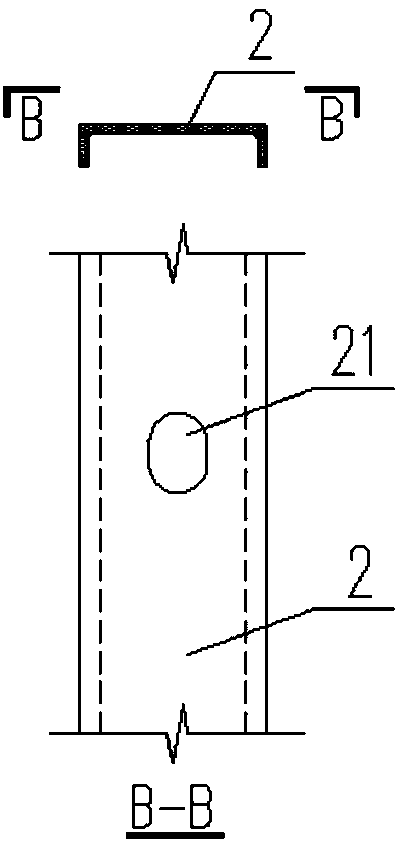

[0029] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 with Figure 12 As shown, a replaceable pre-embedded anchor channel, including channel 1, resin gasket 2, compression ring 3, anchor 4, T-bolt 5, anti-falling gasket 6, anti-falling nut 7 and Concrete segment 8. Described channel is hollow and the quadrilateral of opening is arranged at the bottom, on channel, open oblong hole 11 according to design requirement (see figure 2 ), resin gasket 2 (see image 3 ) is processed into a U-shape just to be buckled on the outside of the channel, and an oblong hole 21 is provided at the corresponding position of the oblong hole in the channel, adding a resin gasket 3 between the channel and the segment can reduce the influence of the channel on the concrete segment, thereby Protect the concrete segment; the compression ring 3 includes three parts: the ring body 31, the wrenc...

Embodiment 2

[0031] Embodiment 2: An installation method of a replaceable pre-embedded anchor channel includes the following steps:

[0032] Step 1: Select suitable anchors, compression rings and resin gaskets according to the channel and T-bolt specifications;

[0033] Step 2: According to the design requirements, install the anchors at a certain distance and embed them in the concrete segments;

[0034] Step 3: Open corresponding long round holes on the channel and resin gasket according to the corresponding spacing;

[0035] Step 4: Install T-bolts on the installed segment first, and fix it in the upper notch with a compression ring;

[0036] Step 5: Install the channel on the outside of the segment through T-bolts, and then fix it with anti-falling gaskets and anti-falling nuts;

[0037] Step 6: When replacing the channel, loosen the anti-falling nut, remove the channel for replacement, and check whether the T-bolt needs to be replaced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com