Expansion anchor

A pin and axial technology, applied in the direction of pins, connecting components, mechanical equipment, etc., can solve the problems of increasing the outer diameter of expansion pins, no longer ensuring the clamping effect of the expansion area, fixing the retention force, and increasing the difficulty of expansion pins, etc. Achieve and economical manufacturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

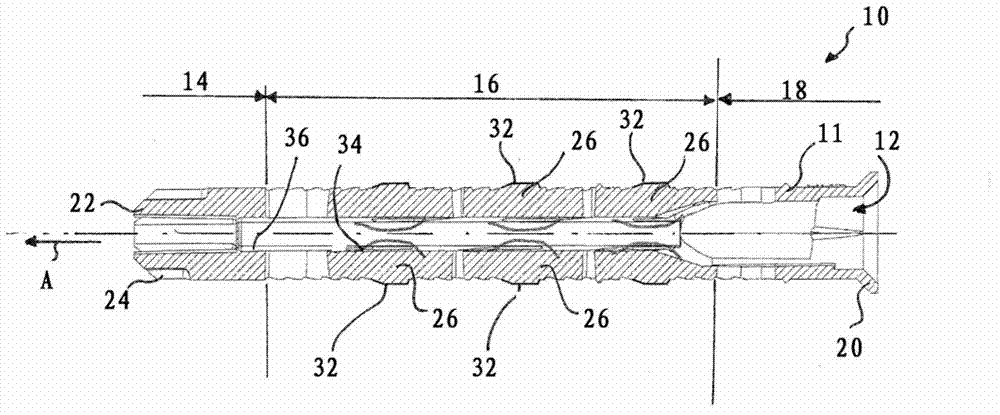

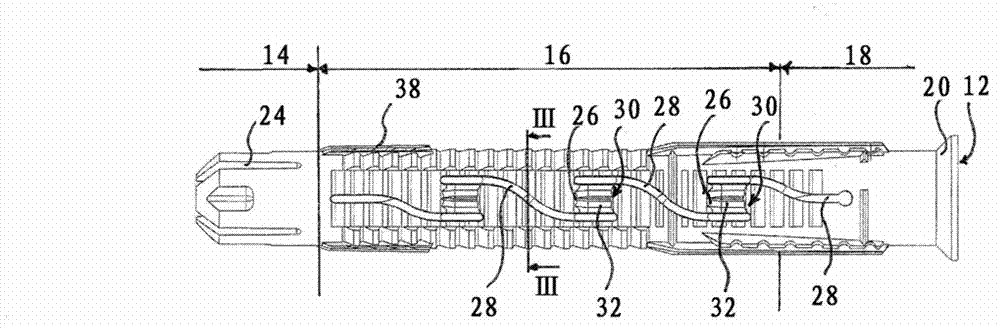

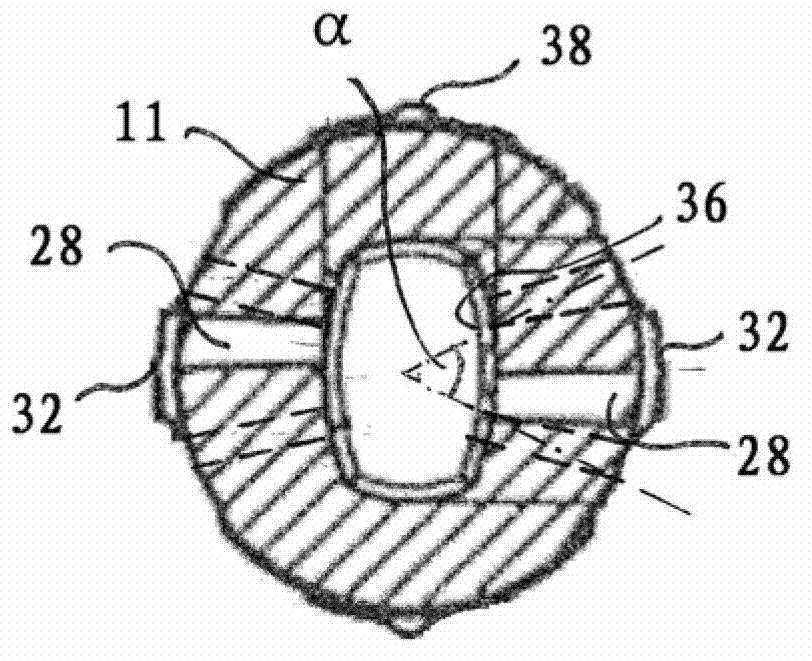

[0024] Figures 1 to 4 Expansion pins 10 shown in are used to secure the component in the substrate. The expansion pin 10 comprises a pin body 11 extending in the axial direction A and having a receptacle 12 (central bore) running in the axial direction A. For installation, the expansion pin 10 is inserted into the borehole of the substrate and is moved into the receptacle 12 through an expansion element (not shown here) in the borehole, expanded and thus clamped in the borehole. . The expansion element is preferably a screw expansion element, which is screwed into the receptacle 12 of the expansion pin 10 . Alternatively, it is also possible to use a snap-in expansion element for this purpose.

[0025] The expansion pin here extends essentially in the axial direction A and has a tip 14 , a clamping region 16 and a head 18 , wherein the receptacle 12 extends through all three regions. Tip 14 serves to center expansion pin 10 during insertion into the substrate borehole and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com