Exhaust gas turbocharger shaft having an impeller

A turbocharger shaft and exhaust turbine technology, applied to machines/engines, components of pumping devices for elastic fluids, non-variable pumps, etc., can solve the problem of limiting the diameter of the compressor wheel and limiting the maximum compressor air throughput etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

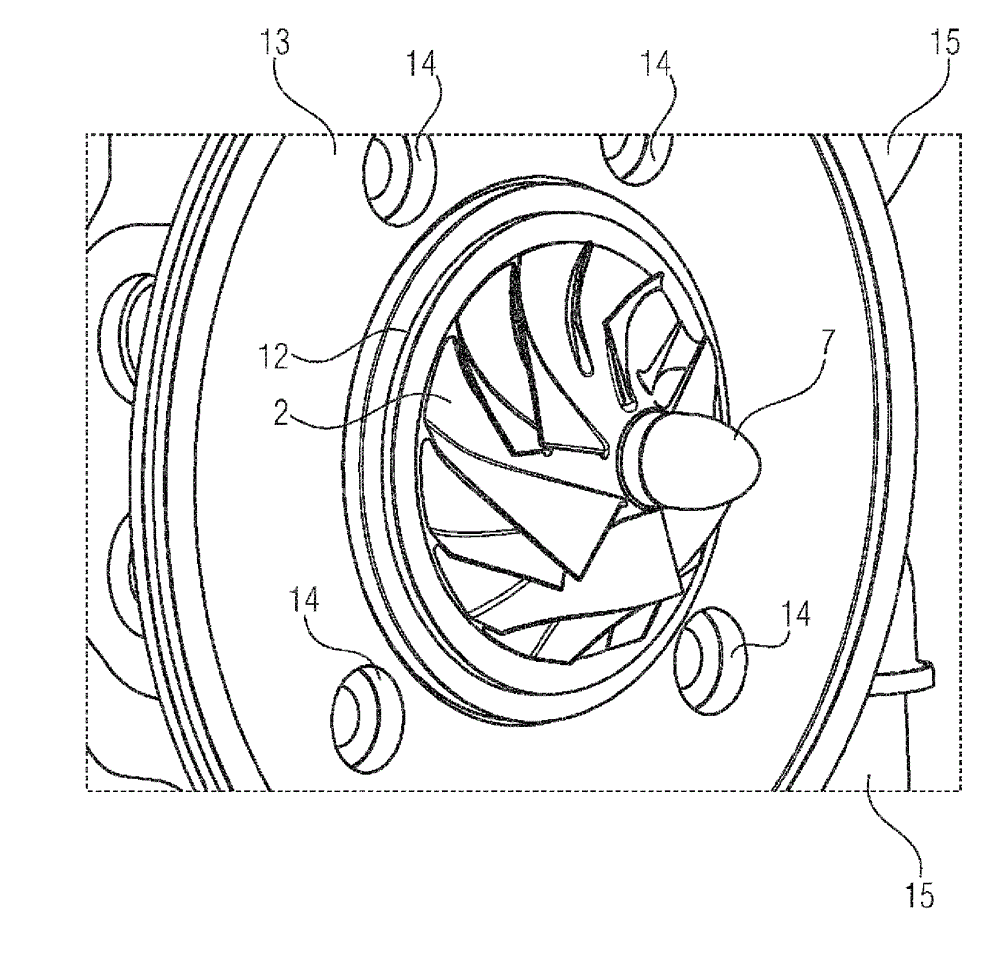

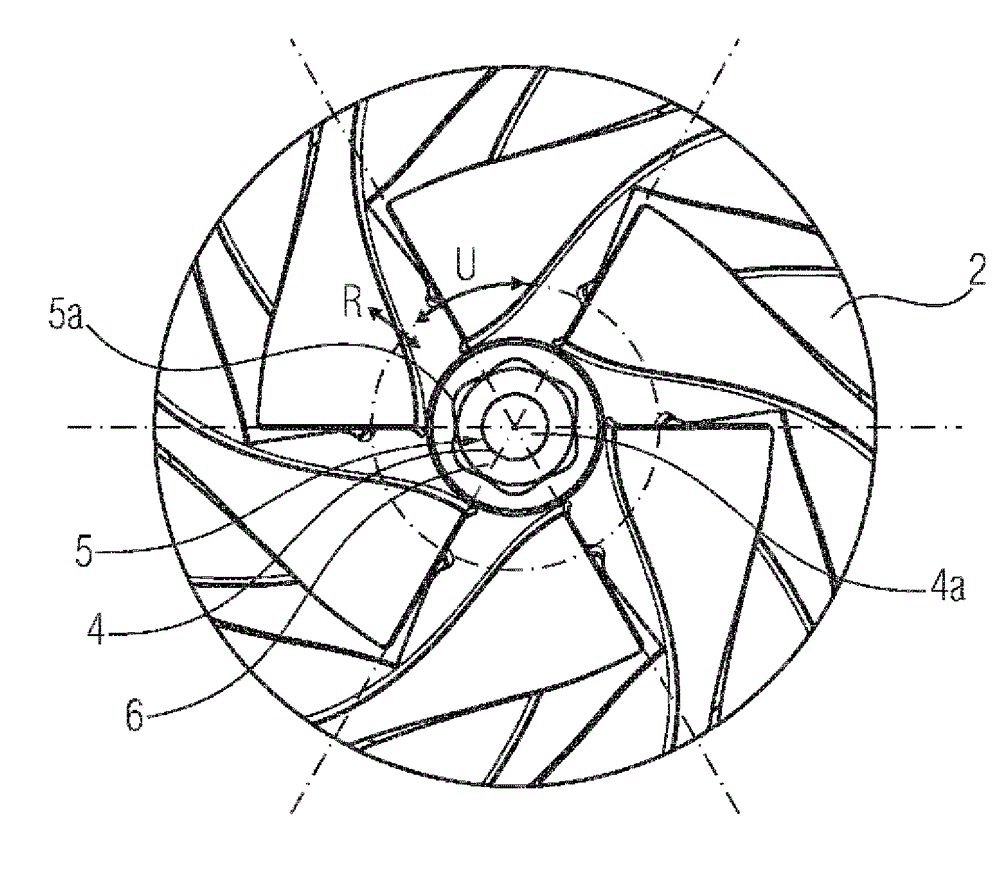

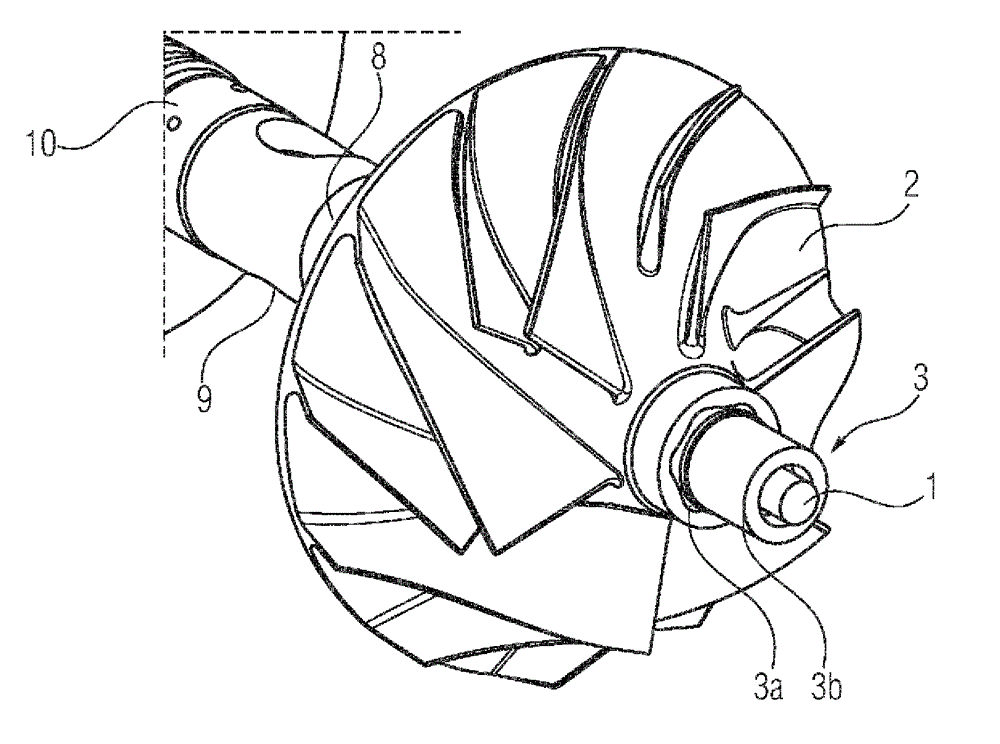

[0016] The invention relates to an exhaust-gas turbocharger shaft having an impeller connected thereto in a form-fitting manner and connected to a shaft nut provided on its outer housing, wherein the shaft nut is inserted into the central hole of the impeller such that the impeller is in contact with the The axle nut forms a form-fit connection in the radial direction and in the circumferential direction.

[0017] The following description is based on an impeller as a compressor wheel of an exhaust-gas turbocharger. However, the invention can also be used in the case of an impeller which is a turbine wheel of an exhaust-gas turbocharger.

[0018] In the present invention, the shaft nut is attached to the outer housing of the exhaust-gas turbocharger shaft. This is achieved, for example, by means of a shaft nut threaded onto its inner housing, the shaft nut being a hex nut, the exhaust-gas turbocharger shaft having an external thread on its outer housing, the hex nut being scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com