Automobile wheel cover special-grab switching plate

A technology for switching plates and wheel covers, which is applied in welding/cutting auxiliary equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of low production efficiency of production lines, low degree of automation, and many wheel covers welding points, etc. Reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

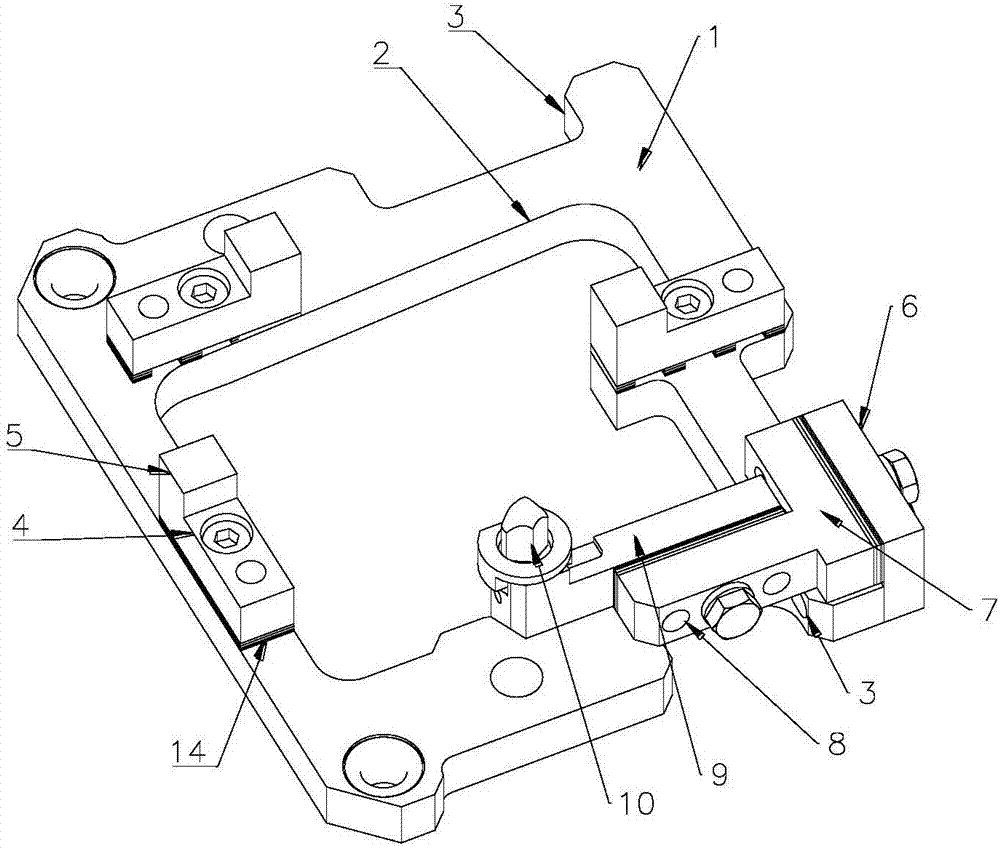

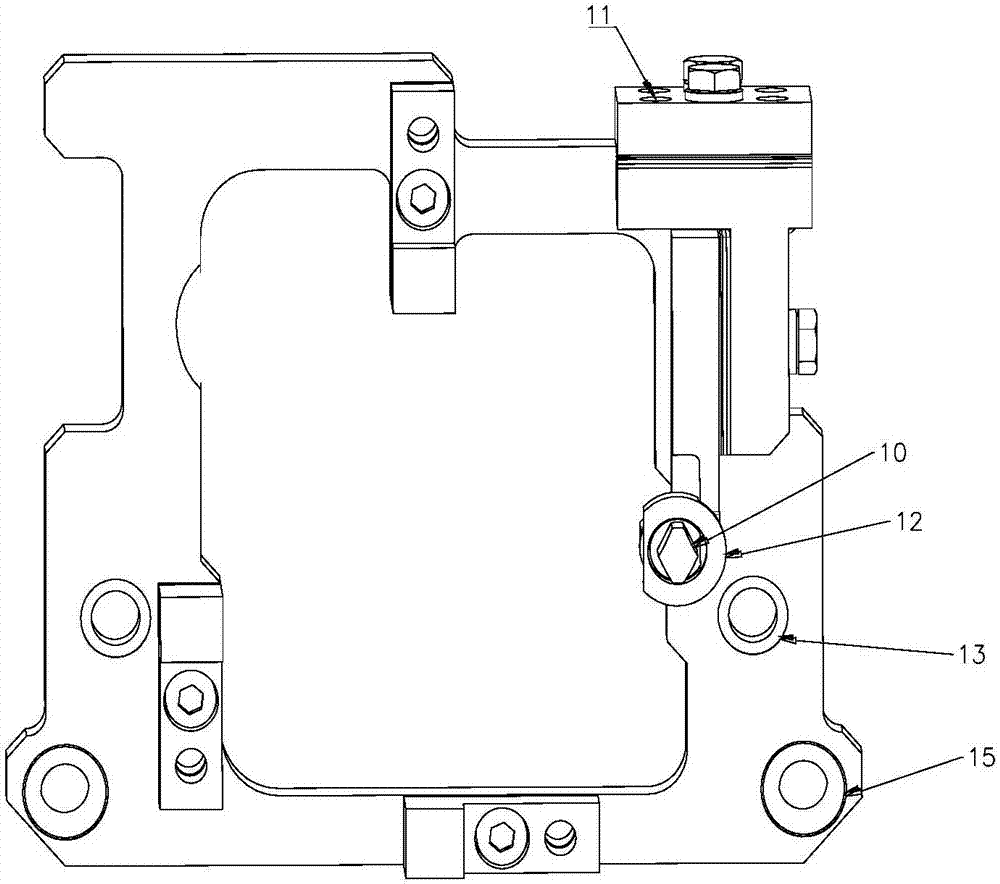

[0016] Such as figure 1 , 2 As shown, the switchboard for the special gripper of the automobile wheel cover includes a connecting plate 1, which is in the shape of a rectangular plate. The middle part of the connecting plate 1 is provided with a rectangular slot 2, and the two symmetrical edges on the outside of the connecting plate 1 are respectively provided with rectangular cutouts 3. The shapes and positions of the rectangular slotted hole 2 and the rectangular slit 3 are designed according to the structure of the wheel cover workpiece and the special gripper, and can also be designed into other shapes, or change the position.

[0017] The surface of the connecting plate 1 is provided with three workpiece supporting blocks 4, and the workpiece supporting blocks 4 are fixedly installed on the connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com