Restoration Structure and Construction Method of Sick Concrete Gravity Dam in Severe Cold Area

A technology for repairing structures and concrete, applied in gravity dams, dams, water conservancy projects, etc., can solve the problems of aging, downstream dam surface freeze-thaw damage, dam body seepage, etc., to achieve strong adaptability to deformation, convenient construction, and anti-seepage effects. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

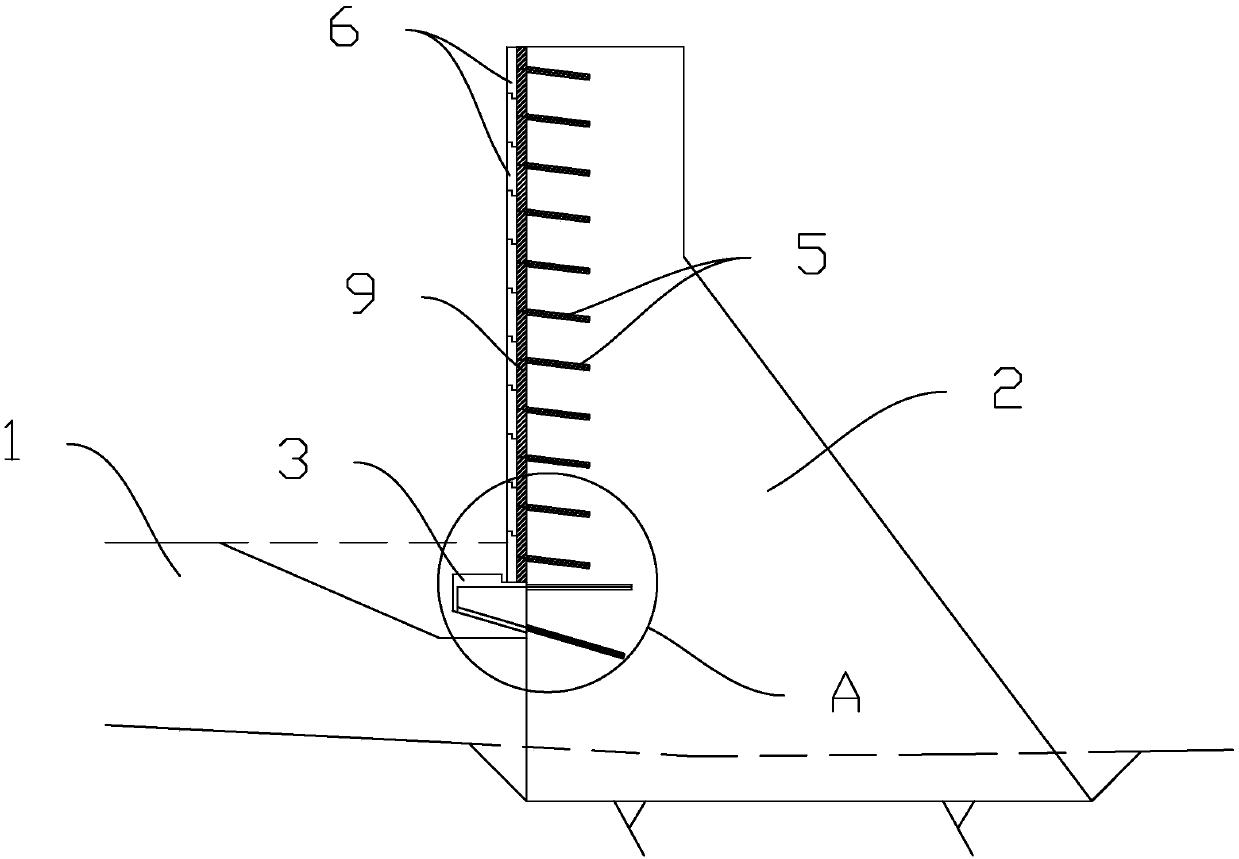

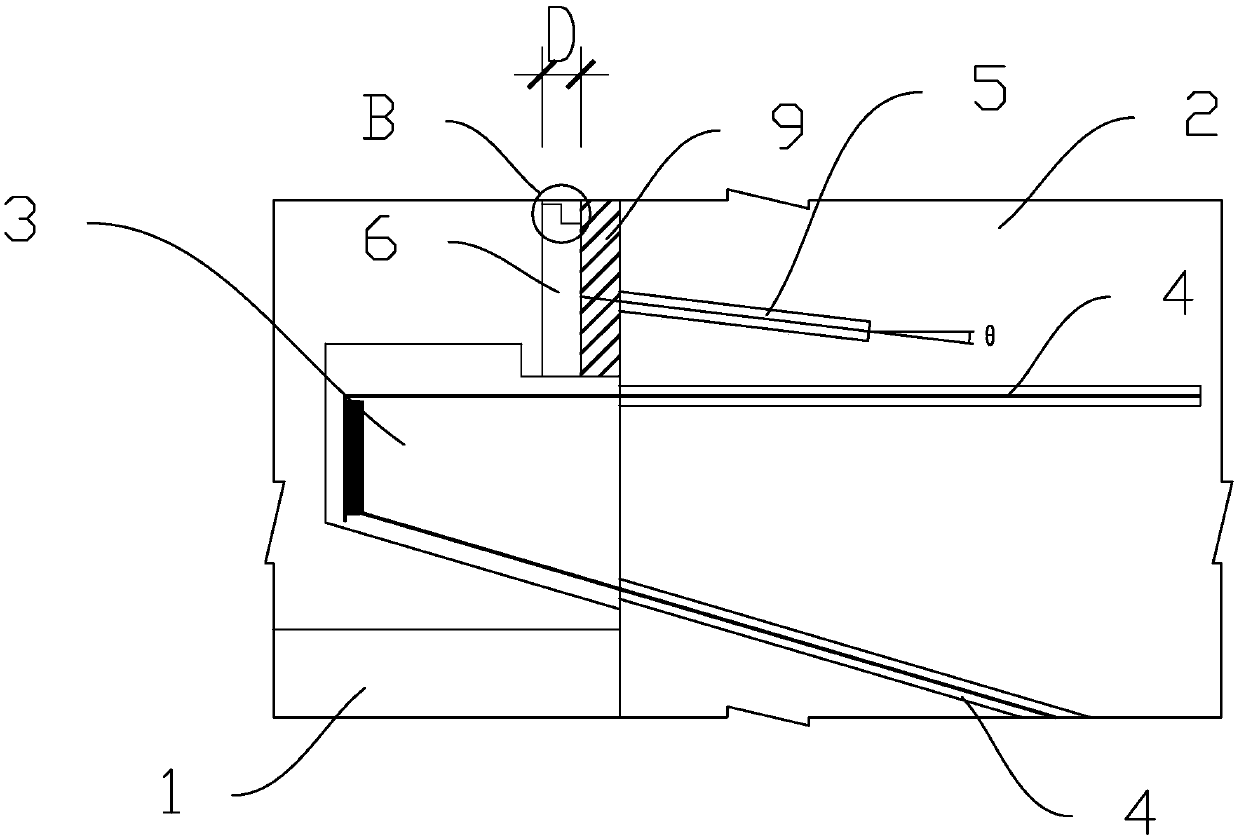

[0031] Such as Figure 1 ~ Figure 4 As shown, this embodiment is a repair structure for a sickly concrete gravity dam in a severe cold area. A corbel 3 is arranged on the upstream surface of the dam body 2 and below the part with poor anti-seepage performance. The corbel 3 is the upper concrete protection plate, asphalt The support body of the concrete anti-seepage plate 9.

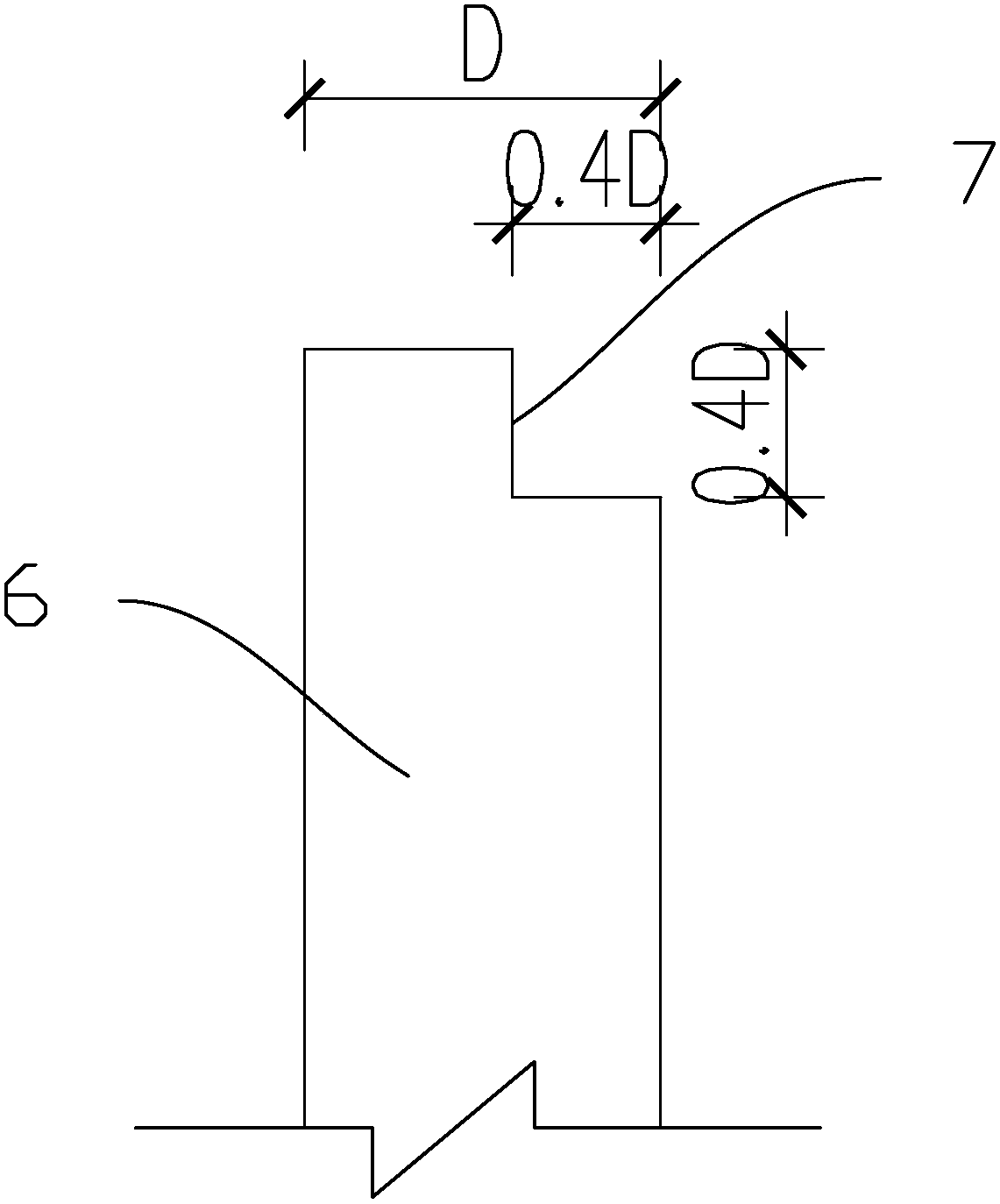

[0032] In this example, above the corbel 3 and at a certain distance (0.1m to 0.2m) away from the water-facing surface of the dam body 2, a concrete protective plate covering the water-facing surface of the dam body 2 formed by lapping and splicing of several concrete prefabricated blocks 6 is provided. Block 6 is shaped on the tongue and groove 7 that is convenient for concrete prefabricated block 6 and concrete prefabricated block 6 lap splicing, and concrete prefabricated block 6 connects dam body 2 through the dam body inserting bar 5 that is embedded in dam body 2 upstream surface. One end of the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com