A method for repairing cracks in earth-rock dam body

A repair method and technology for earth-rock dams, applied in the field of repairing cracks in earth-rock dams, can solve the problems of general repair effect, long construction period, and long setting time, and achieve shortened construction time, low construction cost, and high tensile performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

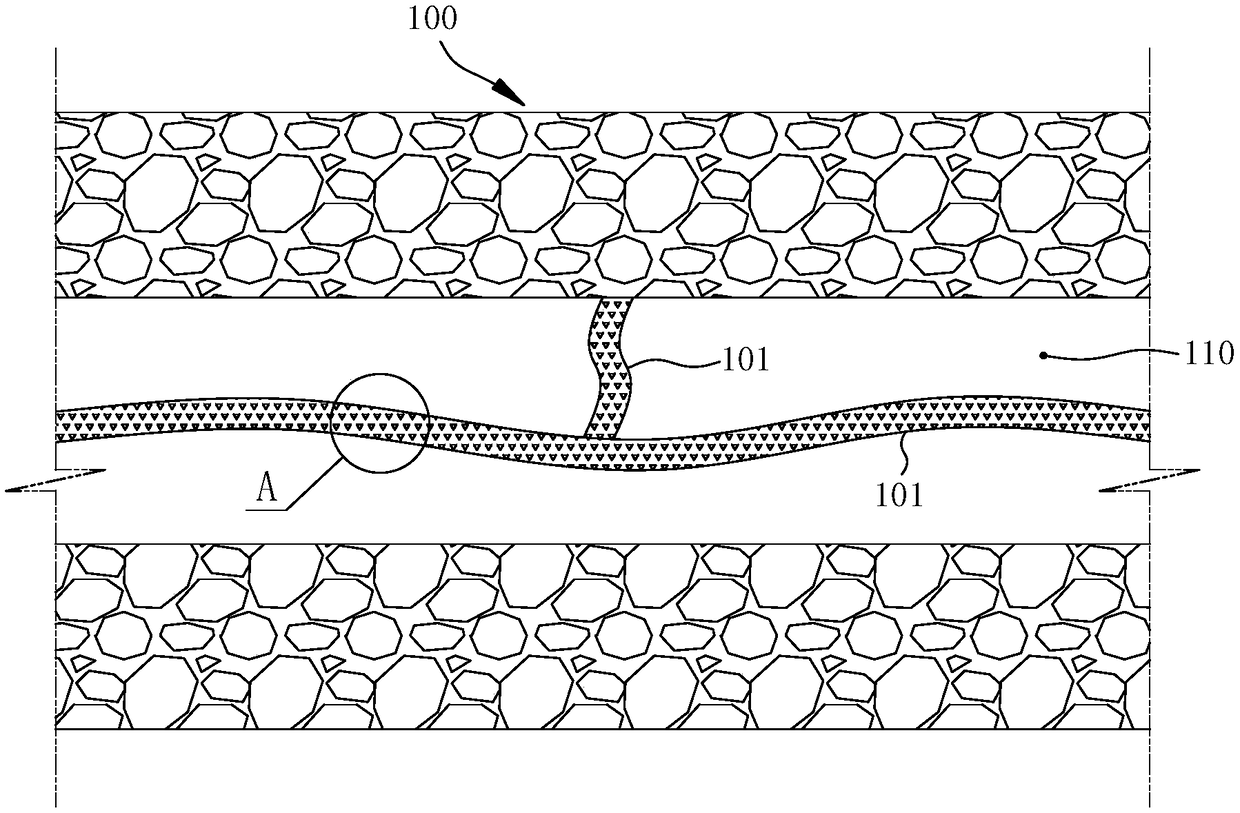

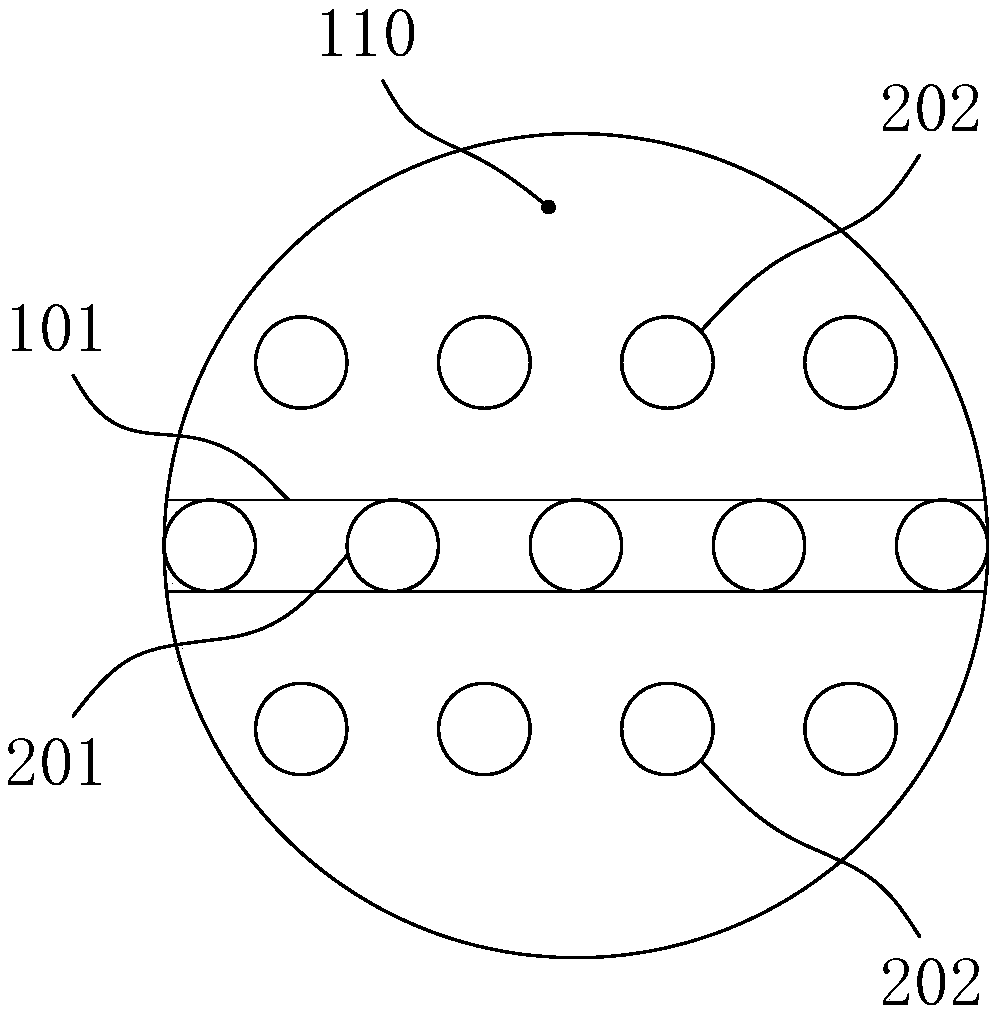

[0036] combine figure 1 and figure 2 As shown, a core rockfill dam located on a deep overburden layer with a dam height of 200m, during the operation of the dam after its completion, a number of longitudinal dam body cracks 101 approximately parallel to the dam axis and vertical dam axis cracks appeared on the dam crest. The transverse dam body crack 101 becomes a potential safety hazard of the dam.

[0037] Utilize the method of the present invention to repair the dam body crack 101 of the above-mentioned core wall rockfill dam, the steps are as follows:

[0038] a. Arrange an in-seam grouting hole 201 at an interval of 2m in the dam body 100 at the dam body crack 101 along the direction of the dam body crack 101; use a drilling tool to arrange the holes, and drill the in-seam grouting hole 201 to the dam 0.5m below the body crack 101, the diameter of the grouting hole 201 set in the crack is not less than the width of the dam body crack 101 where it is set;

[0039]b. Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com