Scour-preventing groove for chain precast block protective surface

A technology of prefabricated blocks and anti-scouring grooves, applied in coastline protection, sea area engineering, construction, etc., can solve the problems of anti-corrosion layer wear failure, easy broken wires, poor durability, etc., and achieve good overall structure durability and economic advantages Visible and durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

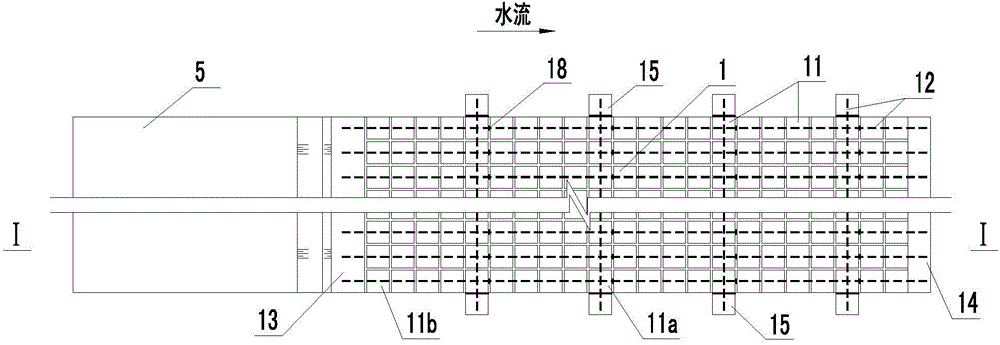

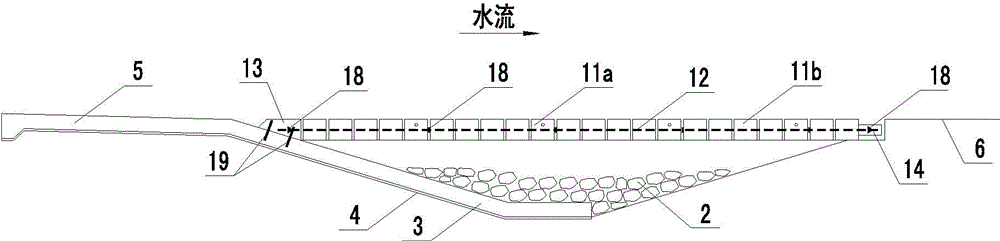

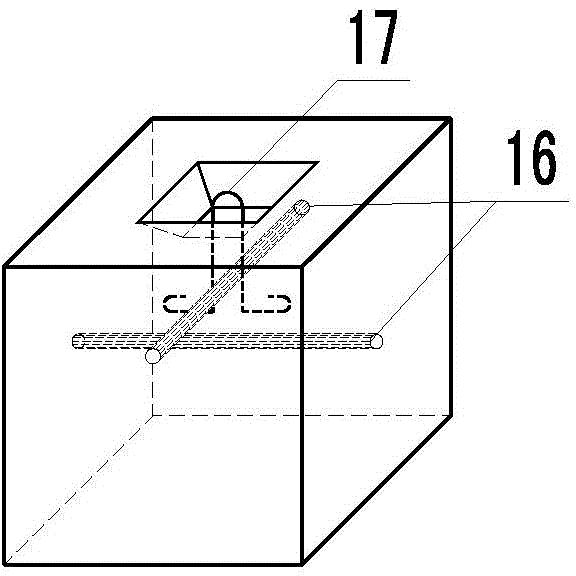

[0032] Such as Figure 1 to Figure 4 As shown, the anti-scouring groove of the interlocking prefabricated block face protection of the present invention includes the interlocking prefabricated block face protection 1, the riprap layer 2 and the bottom extension section 3 of the sea diffuse groove. The structure is poured integrally with the upstream seaman; the riprap layer 2 is thrown and filled on the extension section 3 of the bottom of the seaman trough and the river bed connected to the extension section 3 of the bottom of the trough; the interlocking prefabricated block protection surface 1 is set on the riprap layer 2 above; interlocking prefabricated block armor 1 includes prefabricated block 11, interlocking rope 12, anchor pier 13, anchor beam 14 and anchor head 15, prefabricated block 11 is a concrete cube structure, the side length of the cube is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com