Steel structure combined-type sandwich steel plate rock-fill dam

A combined, steel structure technology, applied in the field of rockfill dams, can solve the problems of large investment, large environmental impact, long construction period, etc., and achieve the effect of reducing environmental damage, low performance requirements, and reduced thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

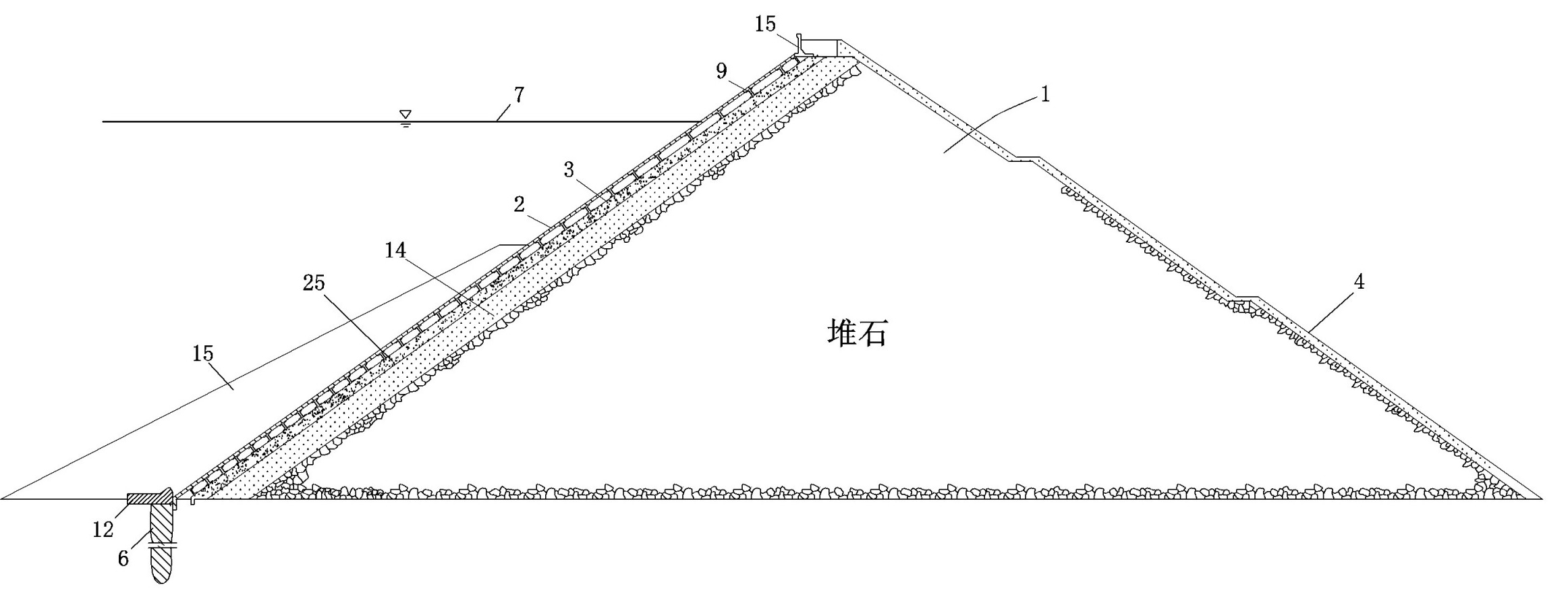

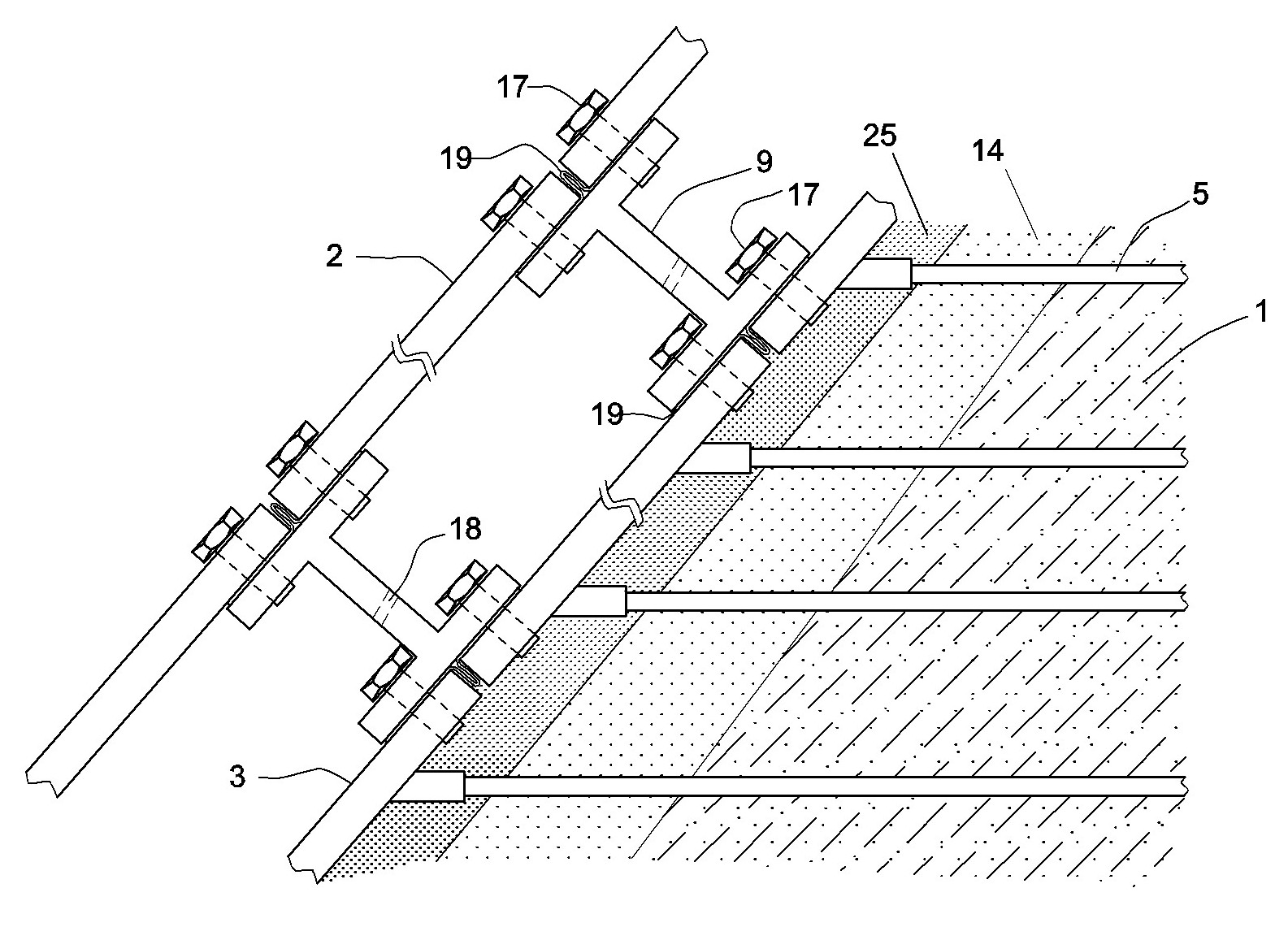

[0036] Embodiment one: see figure 1 — Figure 4 , Figure 7 , a steel structure combined sandwich steel plate rockfill dam, the dam body is a rockfill dam composed of rockfill, the rockfill dam includes cushion area, transition area, rockfill area (main rockfill area and secondary rockfill area Area), the anti-seepage structure composed of steel structure panels, toe slabs on both banks and riverbed toe slabs, as well as the wave wall at the top of the dam and downstream slope protection, and the upstream facing surface of the dam body is set as a combined sandwich steel plate.

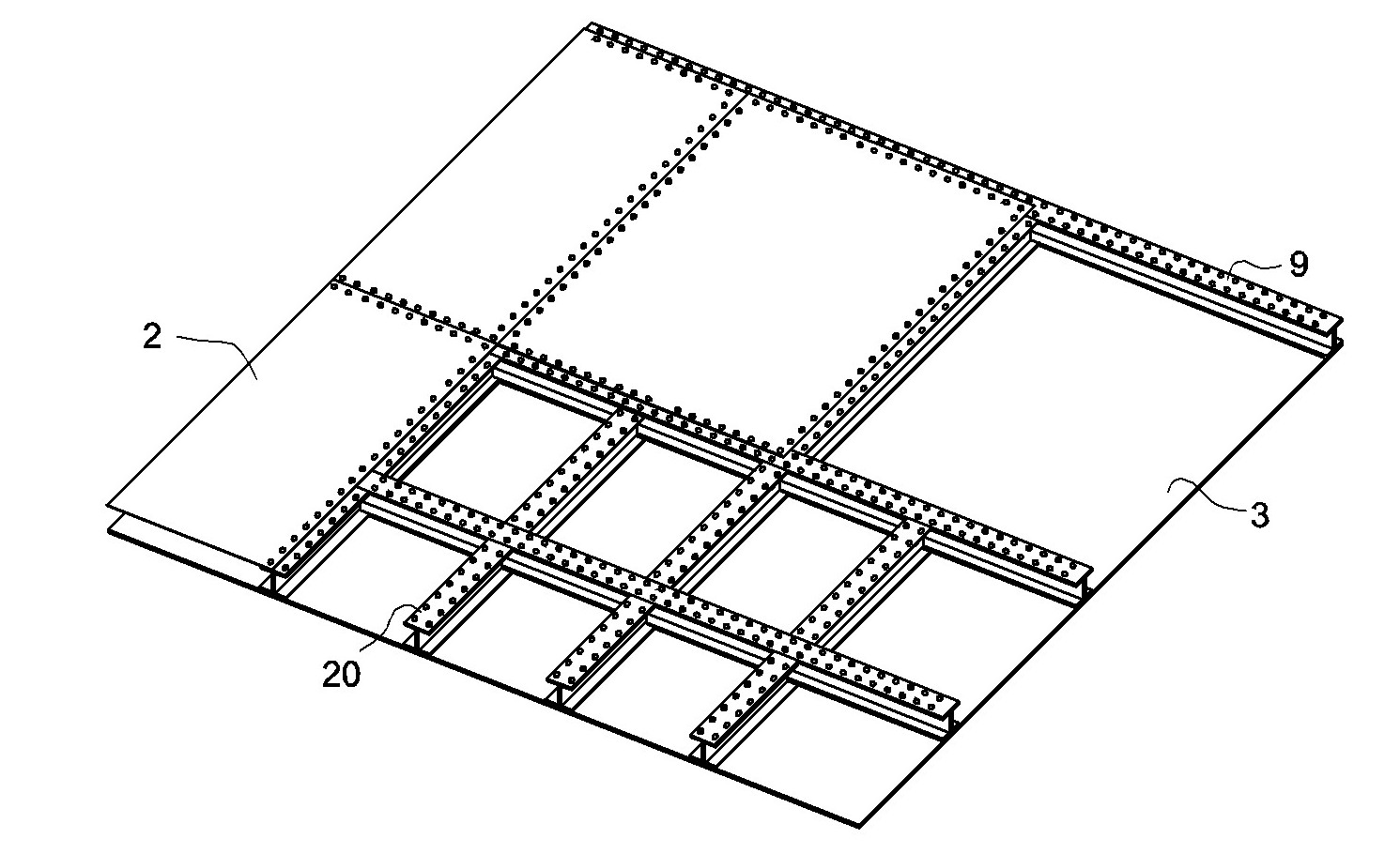

[0037] The combined sandwich steel plate includes an inner layer combined steel plate and an outer layer combined steel plate, and a supporting frame is arranged between the inner and outer layer combined steel plates.

[0038] The inner composite steel plate is attached to the water facing surface of the dam body. The inner steel plate is a plurality of weather-resistant steel sheets that meet the ...

Embodiment 2

[0044] Embodiment two: see Figure 5 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the I-shaped steel is formed by two channel steels fixed by bolts or welding.

Embodiment 3

[0045] Embodiment three: see Figure 6 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that fixed bolts are vertically fixed on the outer surface of the inner single-piece steel plate, and the lower flange of the I-shaped steel is provided with a through hole for use. , there is a layer of sealing sheet between the I-shaped steel and the inner single-piece steel plate, and the through hole is matched and set on the corresponding fixed bolt, and the end of each fixed bolt is fixed with a nut; the upper flange of the I-shaped steel is vertical Fixing bolts are fixed, the outer single-layer steel plate is provided with opposite through holes, and a layer of sealing sheet is placed between the outer single-layer steel plate and the I-shaped steel. And the through hole is set on the corresponding fixed bolt, and the end of each fixed bolt is fixed with a nut.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com