Construction method of scour-filled mortar stone dam with masonry masonry prefabricated block masonry dam shell

A construction method and prefabricated block technology, applied in dams, wall dams, coastline protection, etc., can solve the problems that prefabricated blocks are not suitable for use as gravity formwork, inconvenient for mechanized construction, and high in operation efficiency, and achieve beautiful appearance and automatic orientation. Good condition, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

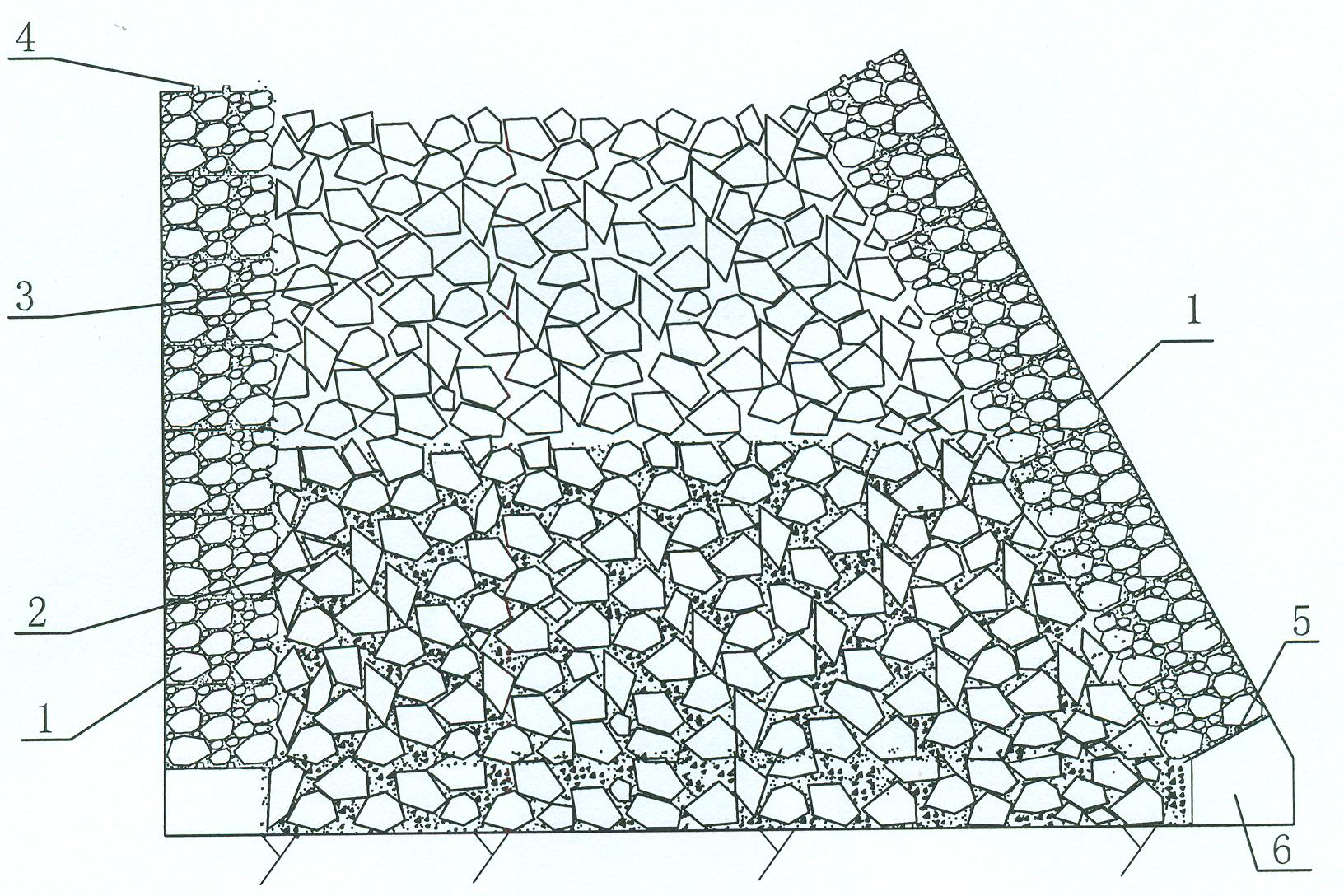

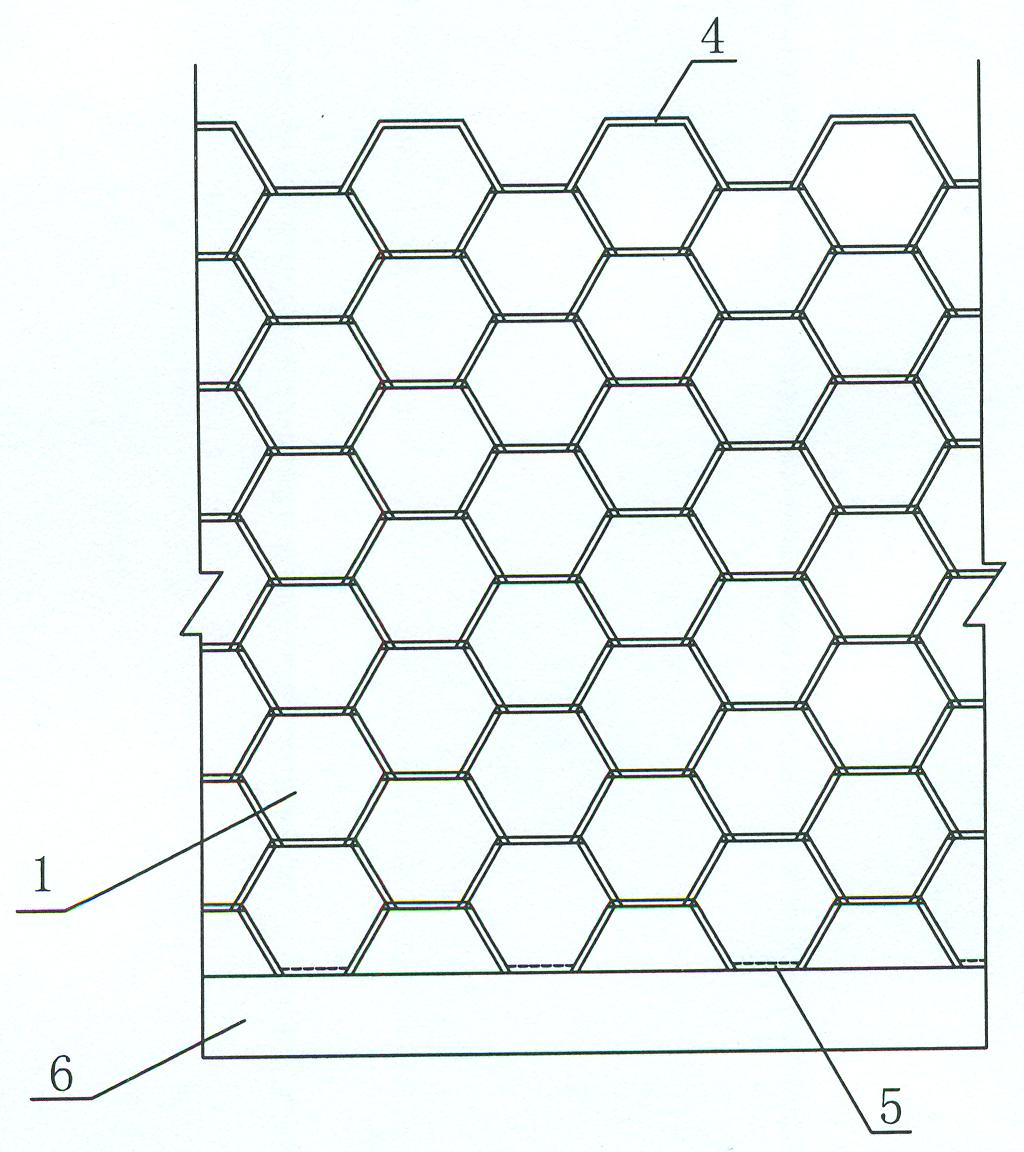

[0036] Example 1: Flush-filled stone dam shell:

[0037] Hexagonal masonry prefabricated blocks with a side length of 50cm~100cm and a thickness of 50~150cm can be used as the dam shell of the scoured stone dam. In order to ensure the effective connection between the dam shell and the dam body, at least 10cm No pulp rough surface. Combined with the gravity formwork action of the dam shell, the blocks are drawn or counter-drawn with steel bars. The dam body can adopt the construction technology of flushing and filling the stone dam, which is filled in layers with natural graded stone materials, and the sand washing process is layered with cement slurry, and the filling is carried out with the filling layer. An innovation in construction technology, maximizing the use of local materials and mechanical construction, reducing construction costs by 50-60%, shortening the construction period by 50-70%, and beautiful appearance.

Embodiment 2

[0038] Example 2: Upstream slope protection project of earth-rock dam:

[0039] The upstream slope protection of earth-rock dams mainly solves the problem of damage to the dam body caused by wind and waves, and at the same time dissipates energy from wind and waves to minimize the height of wind and waves. Conventional slope protection uses block stones, strip stones, rubble materials, and prefabricated or cast-in-place materials are also used. Concrete slab slope protection, due to the technical requirements and aesthetic needs of the upstream slope protection of the dam, dry stone slope protection is used, which has very strict requirements on stone materials. Generally, the transportation distance of stone materials is long, and the price of stone materials is relatively expensive. The cost per unit area of slope protection is close to or exceeds the cost of concrete structures. Moreover, the construction speed is slow by manual work, the quality is difficult to guarante...

Embodiment 3

[0041] Example 3: Masonry gravity retaining wall face protection project:

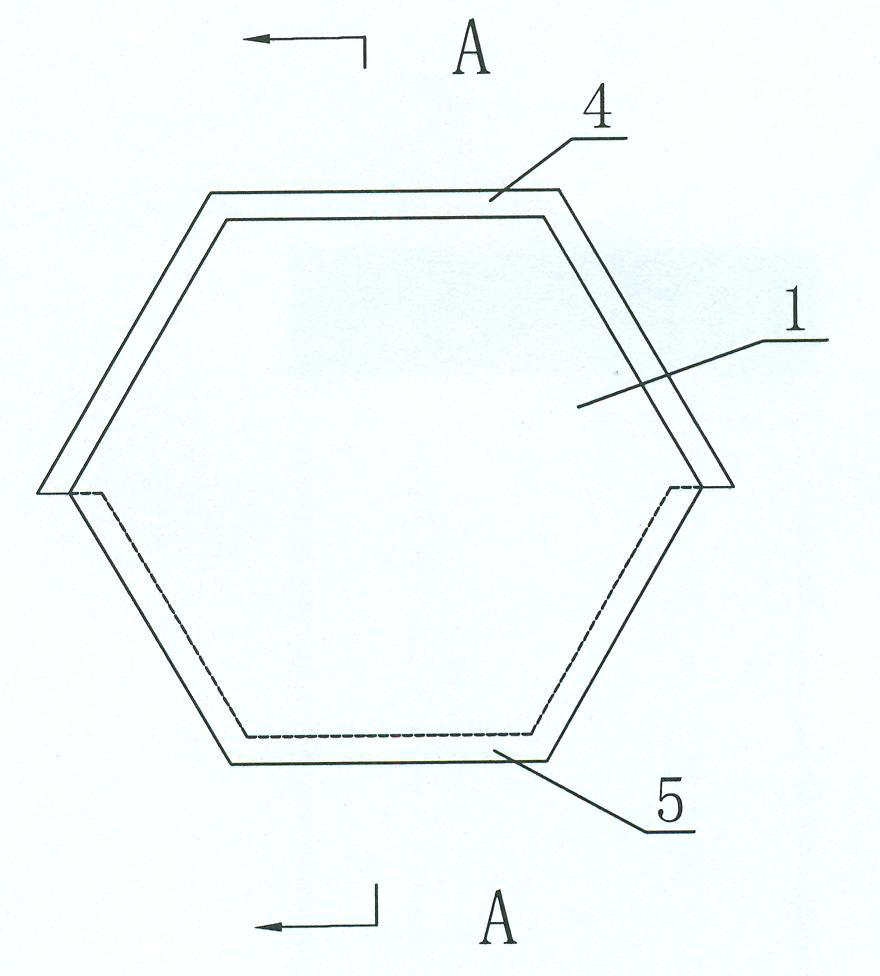

[0042] For the gravity retaining wall below 2.5m in height, the assembled hexagonal mortar masonry prefabricated block structure can be directly adopted, and the prefabricated block can be a regular hexagonal body with a parallel side distance of 80cm. When there is no other load, the thickness of the regular hexagonal body is 90cm, and the regular hexagonal body is provided with two transverse key grooves, so there is no need for a drainage structure behind the wall.

[0043] For higher retaining walls, regular hexagonal masonry prefabricated blocks of the above size can be selected as the protective surface. The inner side of the prefabricated block is rough, and if necessary, steel anchors or double pulls can be used to form a stable whole. The wall can be filled with natural graded stone in layers, and then masonry with mortar or cement mortar to form a gravity retaining wall structure.

[0044]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com