Fixing method for repairing old concrete gravity dam with cracks through FRP

A fixing method and concrete technology, applied in water conservancy projects, marine engineering, construction, etc., can solve problems such as peeling and damage, and achieve the effects of improving work performance, optimizing bonding measures, optimizing bonding measures and material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The method for pasting and fixing the old concrete gravity dam body with cracks to be repaired by FRP sheets will be described in detail below in conjunction with the accompanying drawings.

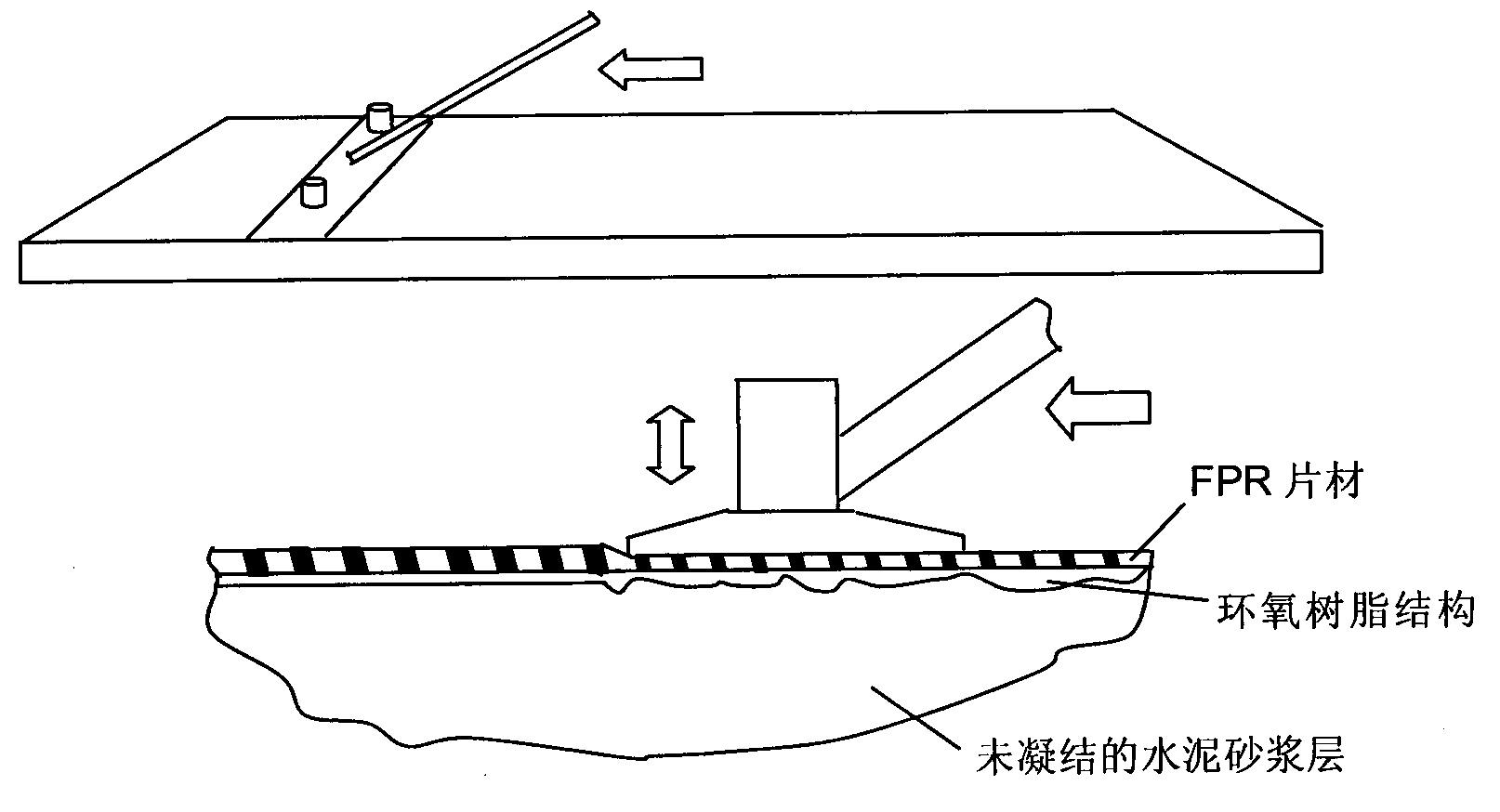

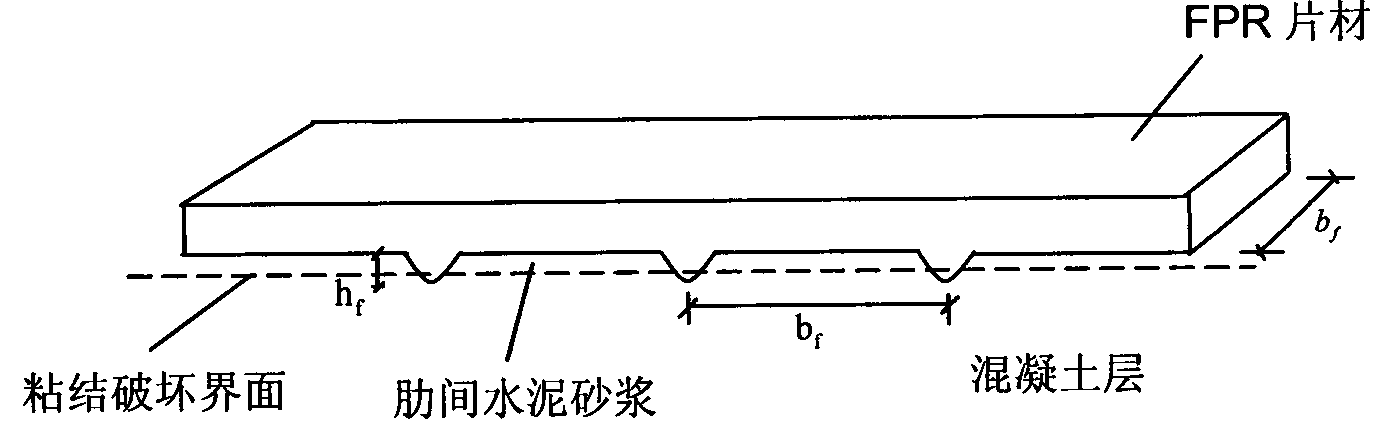

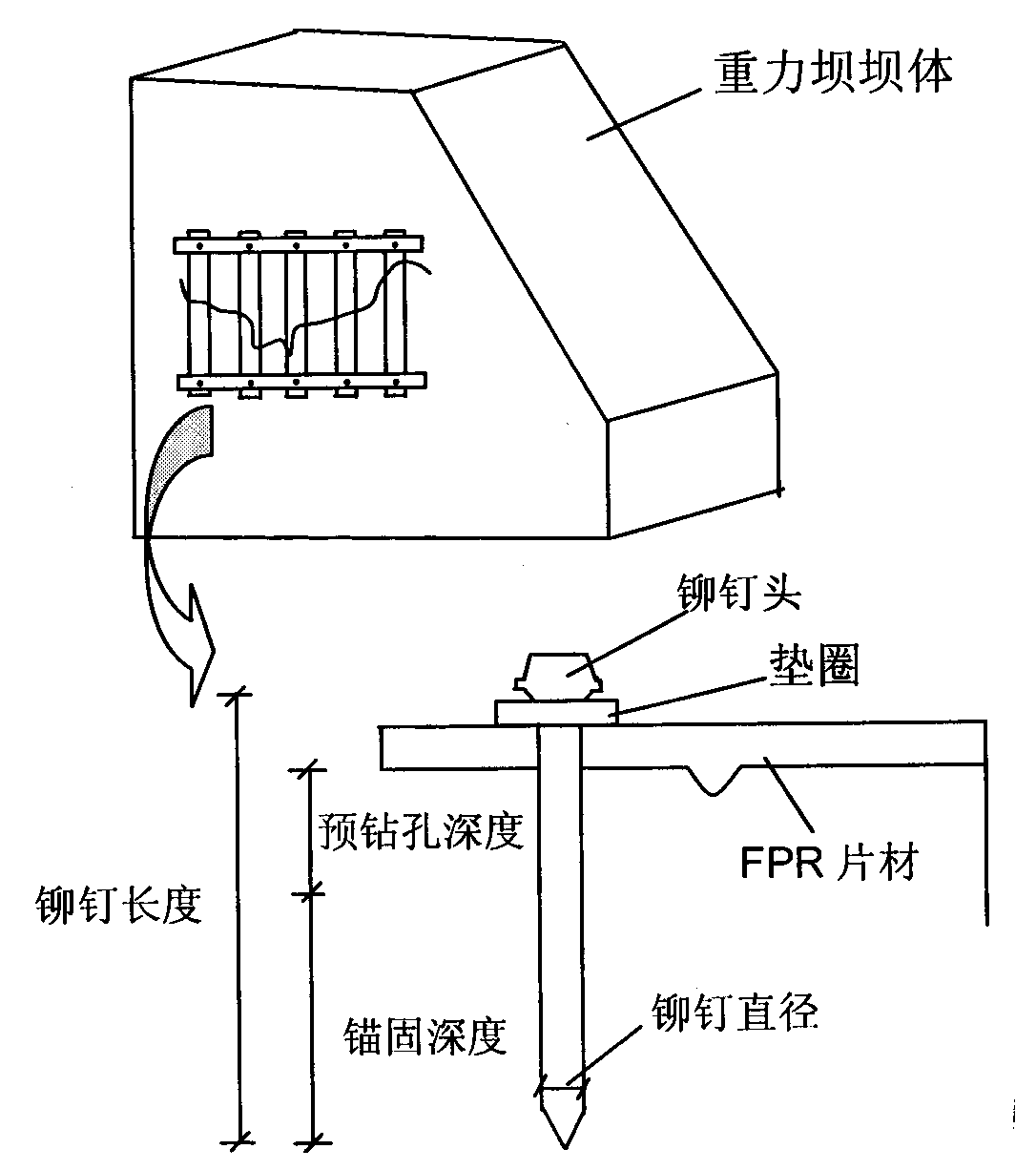

[0011] (1) Grind the concrete surface at the gate pier of the old concrete gravity dam with cracks, clean the severely carbonized concrete, clean the surface with water, and wipe the polished part with acetone, which can improve the bond strength; through the grouting process After filling the cracks with epoxy resin, cover the surface with high-grade cement mortar, trim and level it, and reinforce the dam; before the cement mortar is completely set and hardened, place the ribbed FRP sheet coated with curing agent structural adhesive vertically on the The cracks are glued to the unhardened cement mortar surface, using such as figure 1 The rolling device shown is rolling while vibrating, so that the ribbed FRP sheet and the cement mortar layer are firmly bonded together. The ribs of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com