Patents

Literature

58results about How to "Limit slip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

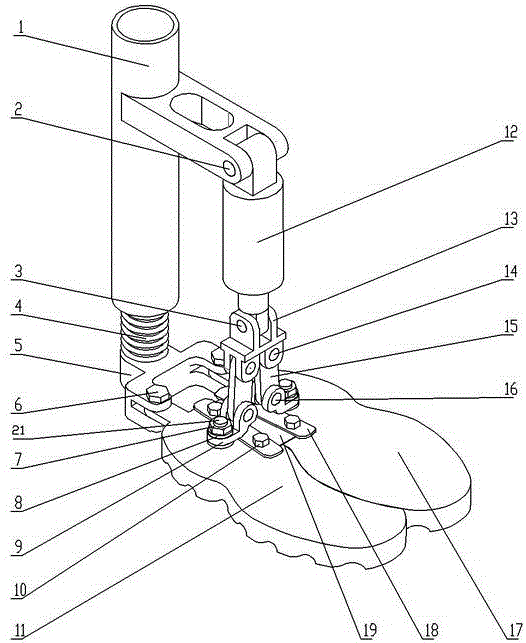

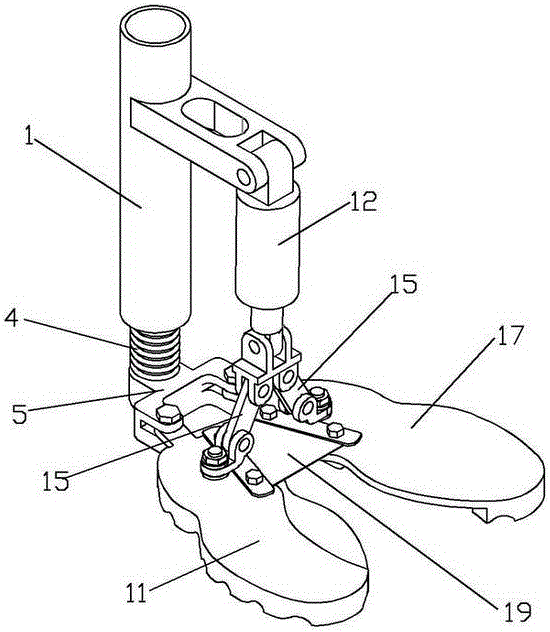

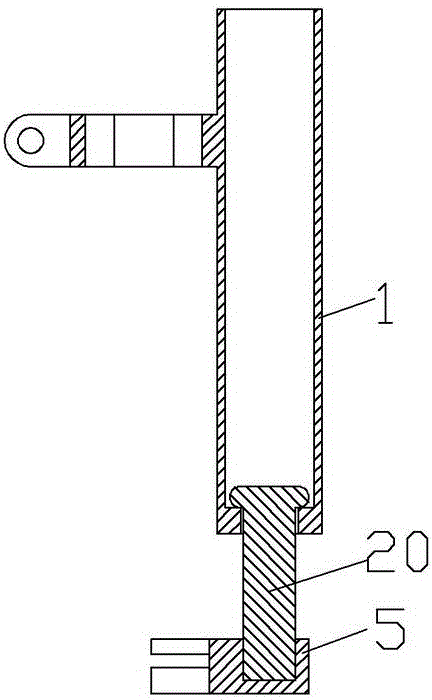

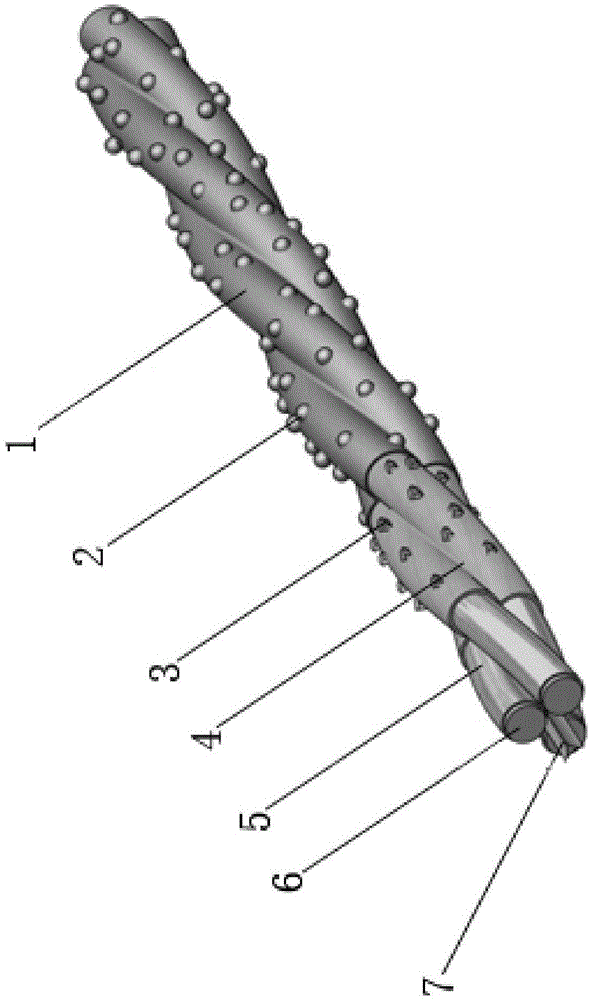

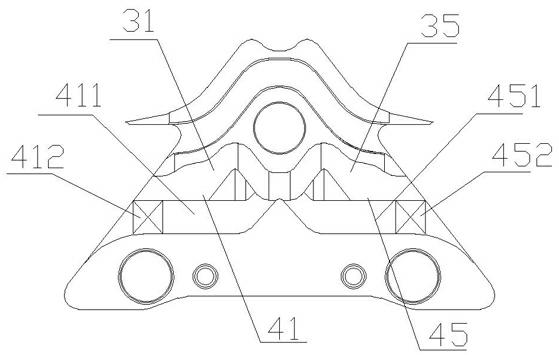

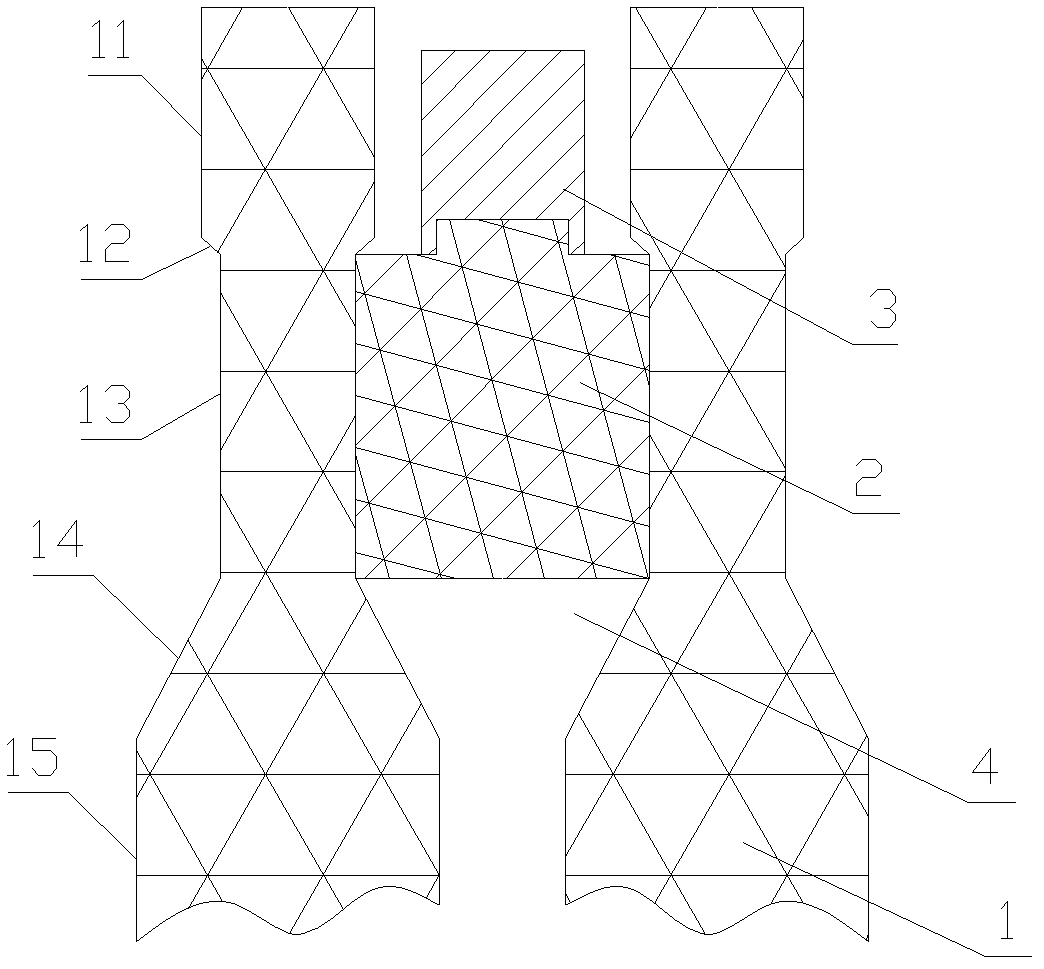

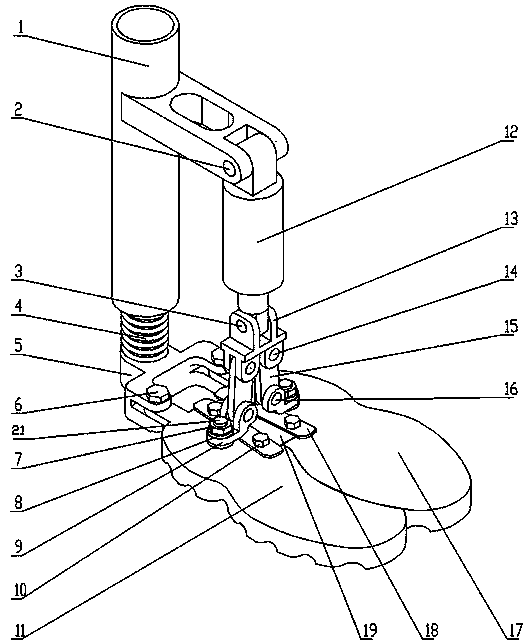

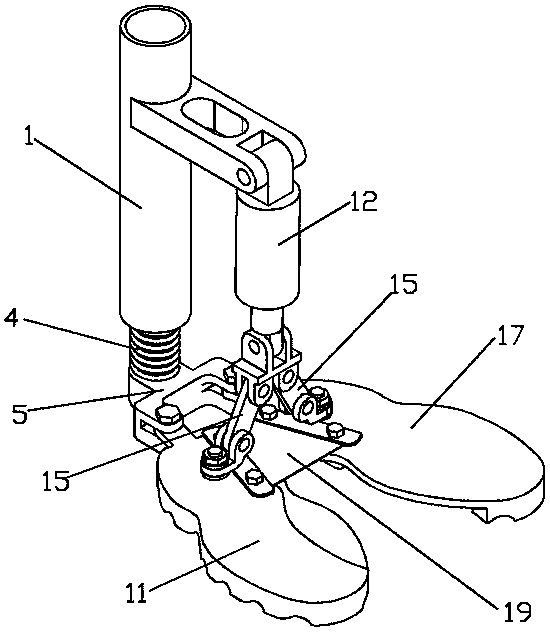

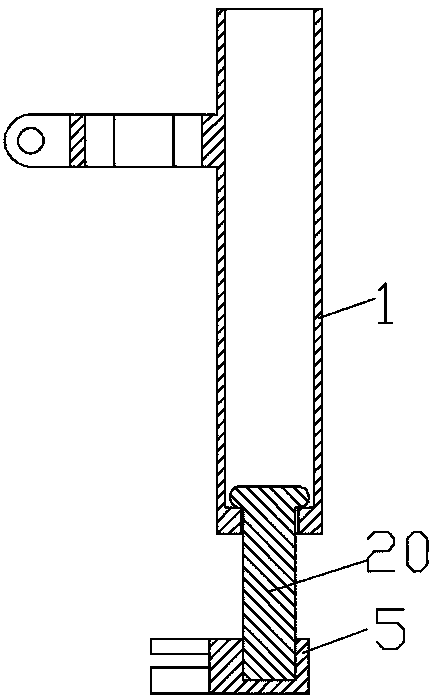

Self-adaption sand land biomimetic mechanical foot

The invention discloses a self-adaption sand ground biomimetic mechanical foot, and belongs to a foot type robot mainly applied to walking on sand ground. The self-adaption sand ground biomimetic mechanical foot consists of a support frame, a linear motor, a connecting element, a first foot toe, a second foot toe, an elastic fabric, a buffer mechanism and the like, wherein the connecting element consists of a first connecting element, a second connecting element, a pin shaft and a screw stud; the buffer mechanism consists of a support frame, a foot sole, a spring and a connecting post, and is used for simulating an ostrich tarsometatarsus joint to achieve the buffer and shock absorption effects. The self-adaption sand ground biomimetic mechanical foot can achieve the beneficial effects that when the robot walks on the sand ground, the two toes are separated when the foot touches the ground; the elastic fabric spreads, so that the ground contact area is increased; the stability of the robot is improved; when the foot is lifted up, the two toes are closed and are overlapped for a certain area; the elastic fabric contracts; the stress area in the moving process is reduced. Meanwhile, the bottom of the first foot toe and the bottom of the second foot toe are provided with groove structures matched with the elastic fabric; the sand fixing and current limiting functions can be realized; the gait stability and the traction performance of the foot type robot can be improved.

Owner:JILIN UNIV

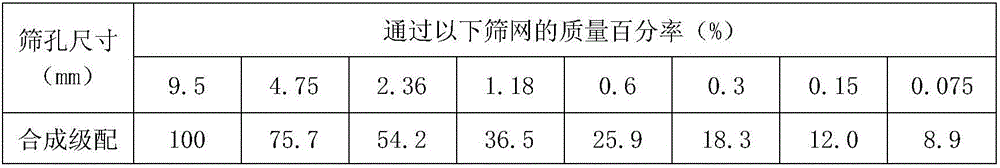

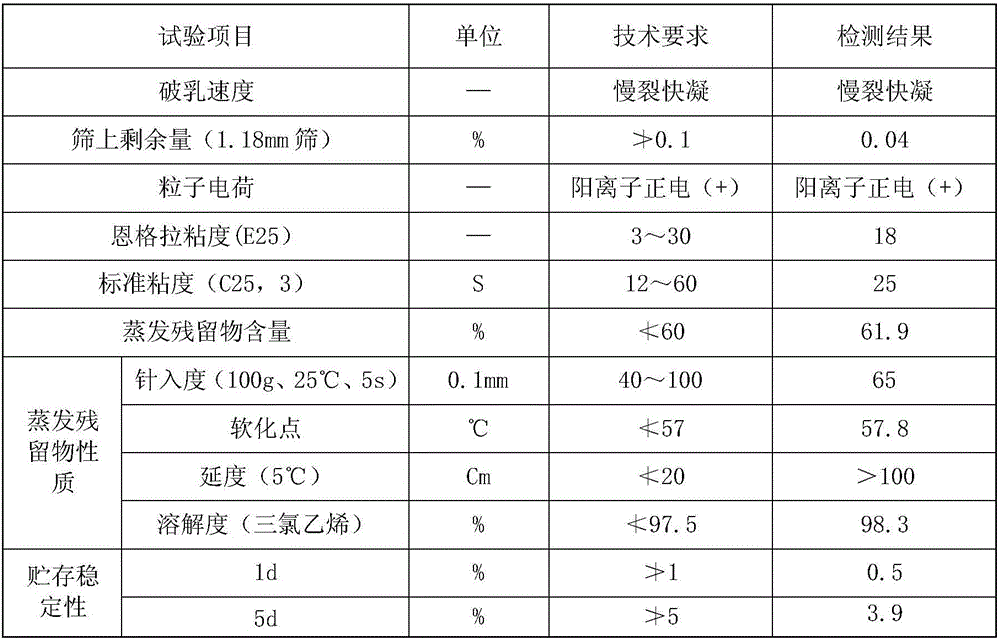

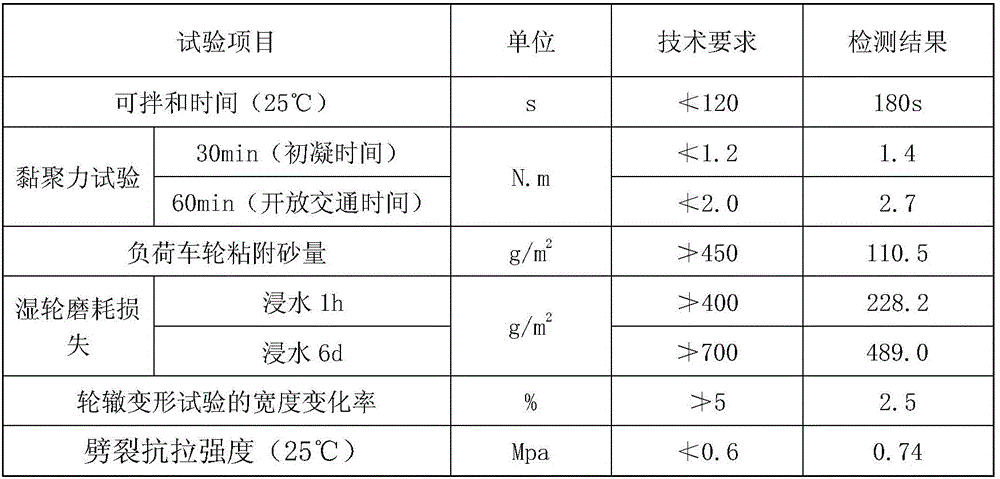

Super-viscose fiber wearing layer cold-mixed asphalt mixture and preventive maintenance method of asphalt pavement

InactiveCN106007489AReduce energy consumptionAvoid energy consumptionRoads maintainenceFiberPolymer modified

The invention relates to a pavement construction material and a pavement construction method, in particular to a cold-mixed asphalt mixture for a super-viscous fiber wear layer and a preventive maintenance method for an asphalt pavement. The composition and mass percentage of the ultra-viscosity fiber wearing layer cold mix asphalt mixture of the present invention are: polymer modified emulsified asphalt (9-15)%, aggregate (75-80)%, filler (0.5-3)% , fiber (0.1~0.3)%, rubber powder (0~3)%, water (5~10)%, the total amount is 100%. The material of the invention has good wear resistance, adhesion and water resistance, strong anti-crack ability of the construction road surface, good stability and convenient construction.

Owner:JIANGSU TIANNUO ROAD MATERIAL TECH

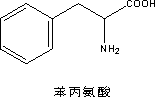

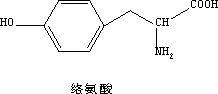

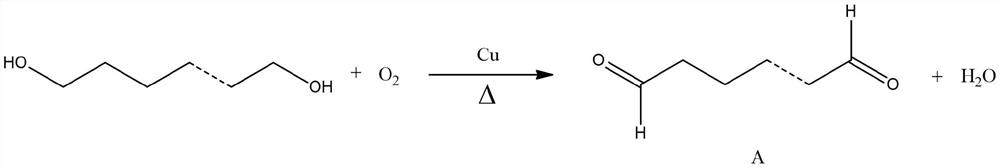

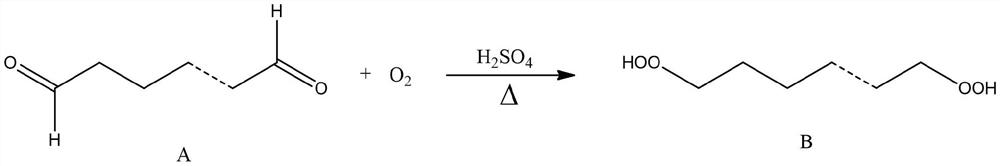

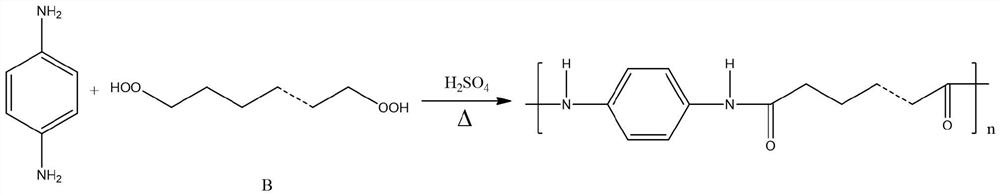

Adhesive for nano-silicon carbon anode material of lithium battery and preparation method of adhesive

InactiveCN108428895AHigh tensile strengthIncrease elasticityCell electrodesSecondary cellsSilicon electrodeCarboxylic group

The invention discloses an adhesive for a nano-silicon carbon anode material of a lithium battery. The high-molecular polymer adhesive is prepared from amino acid containing amino and polymers containing carboxyl or ester by condensation; amino in amino acid is subjected to a reaction with carboxyl in PAA (polyacrylic acid) or ester in polyacrylate and dehydrated to form an amido bond, then a high-molecular polymer with a three-dimensional network structure is formed, and synergistic effect of amino in amino acid and carboxyl is utilized sufficiently, so that the polymer has excellent mechanical property and machinability and high tensile strength and elastic restoring force. The adhesive can effectively limit change of electrode thickness in a lithium-intercalation process, an electrode also has better recovery capability in a lithium separation process, structural stability of the silicon electrode in the lithium separation / intercalation process is effectively kept, and the defect that volume of a silicon pole piece is extremely prone to expanding in a charge-discharge process is overcome.

Owner:中国东方电气集团有限公司

Textile-based enhanced degradable tube cavity support and preparation method and application thereof

The invention provides a textile-based enhanced degradable tube cavity support and a preparation method and application thereof. The textile-based enhanced degradable tube cavity support is characterized by comprising a hollow tubular fabric formed by two-dimensionally and three-directionally knitting degradable macromolecular silk yarns as knitting silk yarns, wherein axial silk yarns are introduced between two groups of knitting silk yarns in the knitting process and are not knitted, the axial silk yarns are molten through a heat treatment process, weaving points of the two groups of degradable macromolecular silk yarns are bonded and fixed through the molten axial silk yarns, and accordingly the textile-based enhanced degradable tube cavity support stable in shape is obtained. The shortcoming that the edge knitted by a machine is easy to loosen and a structure is not easy to fix can be effectively overcome, slippage of the weaving points of the support can be effectively prevented, the number of the weaving points per unit length when the support is radially compressed is increased, and the radial supporting force of the support is increased.

Owner:DONGHUA UNIV

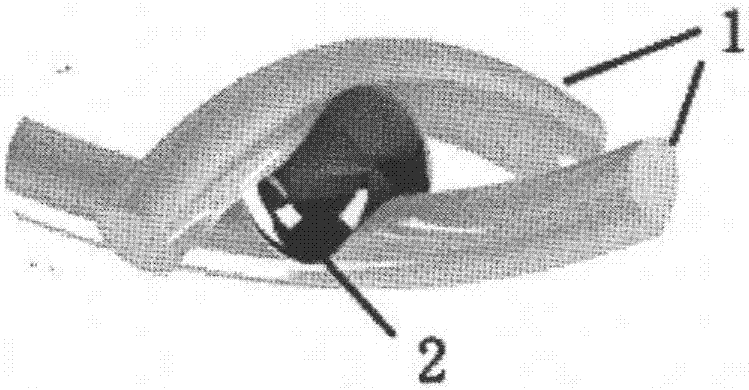

Swing self-resetting damping system for middle column of underground station and construction method of swing self-resetting damping system

ActiveCN110468986ANo plastic failureRealize self-resetting functionStrutsProtective buildings/sheltersContact typeRestoring force

The invention discloses a swing self-resetting damping system for a middle column of an underground station and a construction method of the swing self-resetting damping system. The swing self-resetting damping system is constituted by a top plate, a bottom plate, the prefabricated middle column, a pre-buried steel part and an energy dissipation steel plate; the traditional connection mode of fixed connection of the middle column, the top plate and the bottom plate is changed into the mode that the middle column, the top plate and the bottom plate are subjected to structure-contact-type hingedconnection and connected into a whole through unbonded prestressed steel strands, structure connection joints are connected in a hinged mode instead of a fixed mode, and thus the middle column becomes a controllable swing damping component; meanwhile, structural self-resetting function can be achieved under the effect of the upper structure load and elastic restoring force of the unbonded prestressed steel strands; the energy dissipation steel plate achieves an energy dissipation damping effect, stress is evenly distributed in the plates in the mode of preforming holes, multiple areas of theenergy dissipation steel plate enter into a plastic state advantageously, and the energy dissipation effect is improved; and protruded hemispherical embedded joints at the top and the bottom of the middle column can effectively achieve the effect of transmitting shearing force, column end sliding can be limited, and the unbonded prestressed steel strands can also be prevented from being subjectedto shear failure.

Owner:HENAN UNIVERSITY

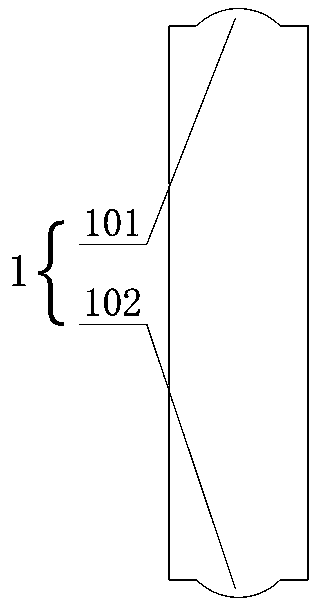

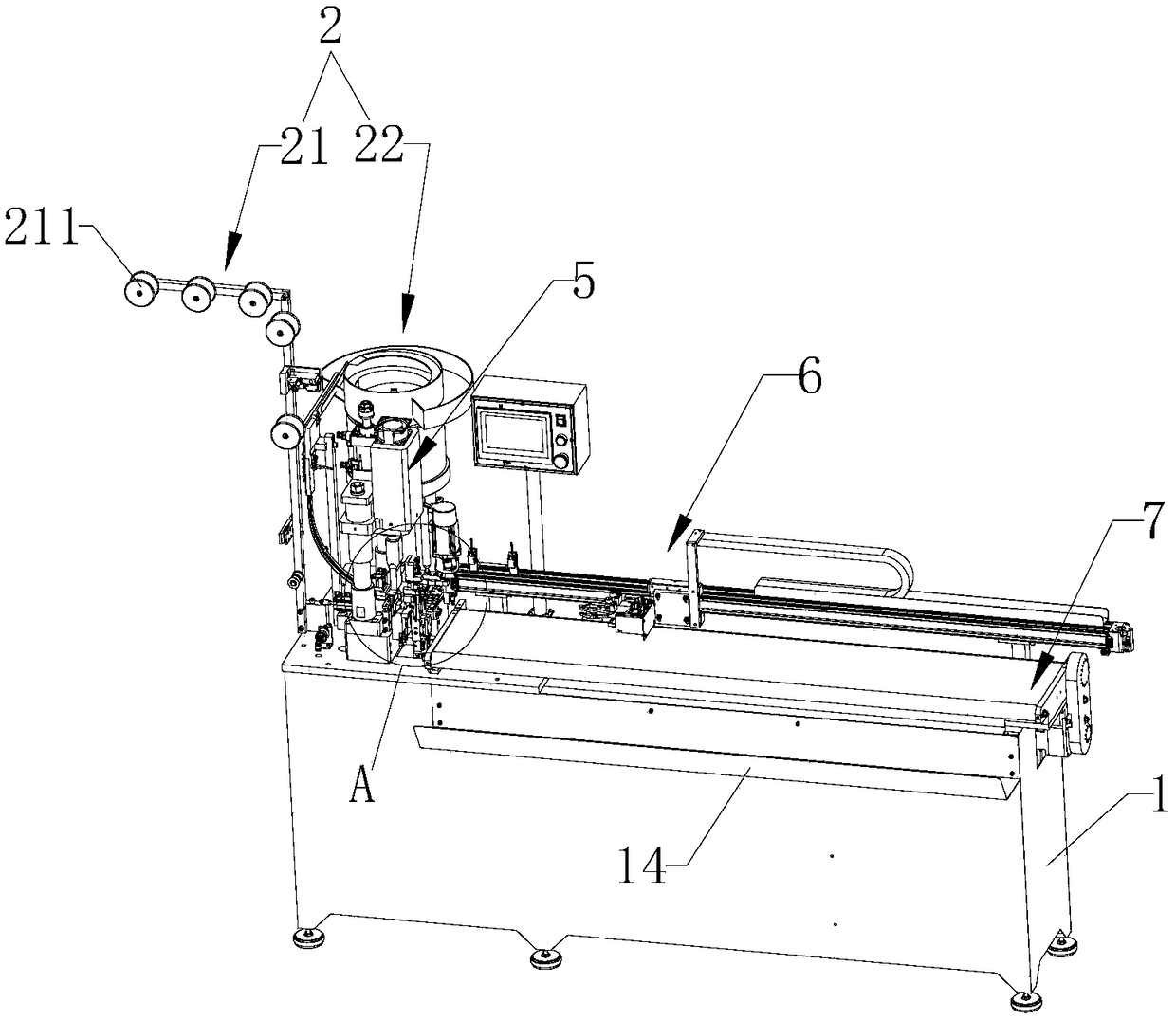

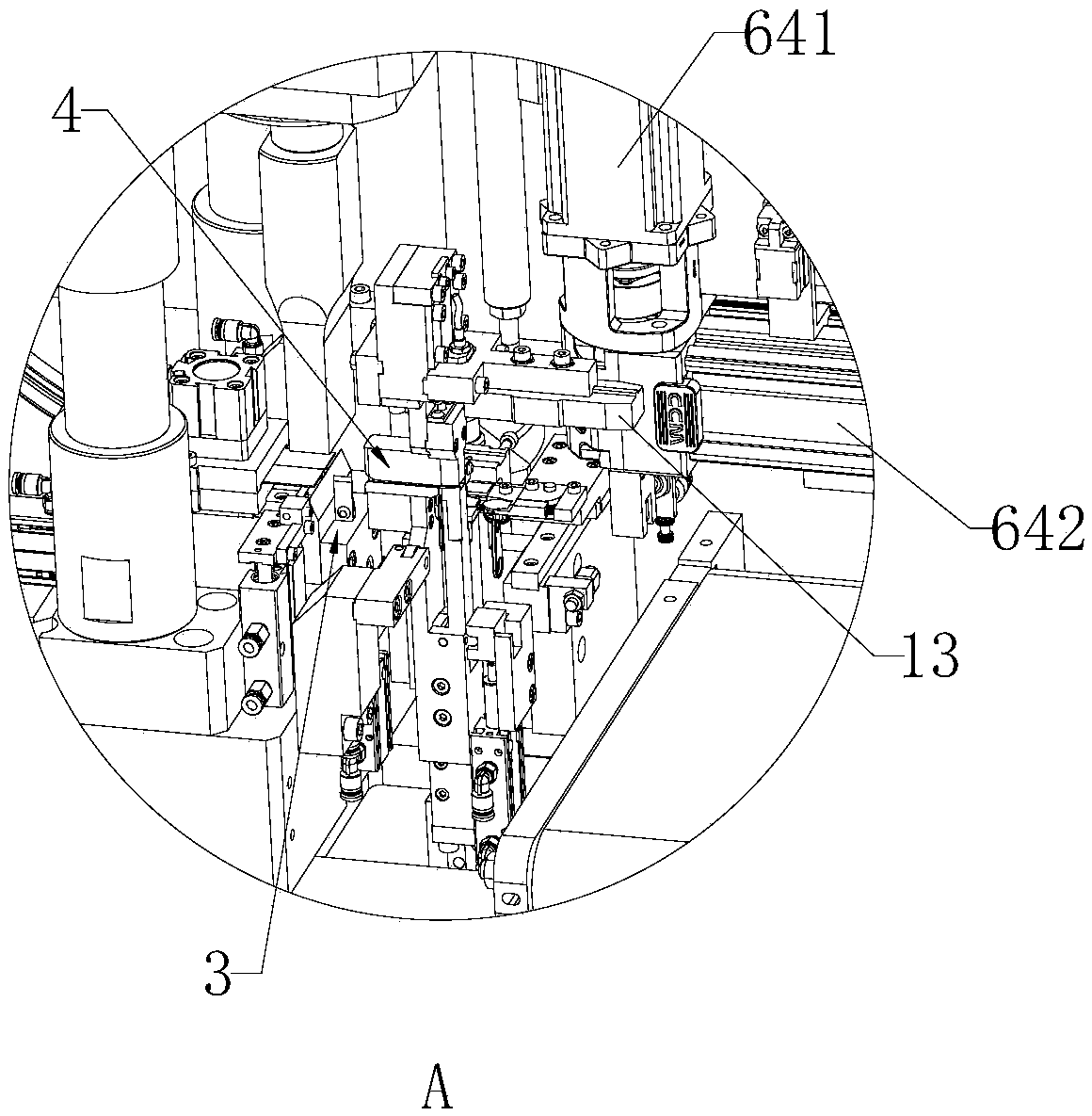

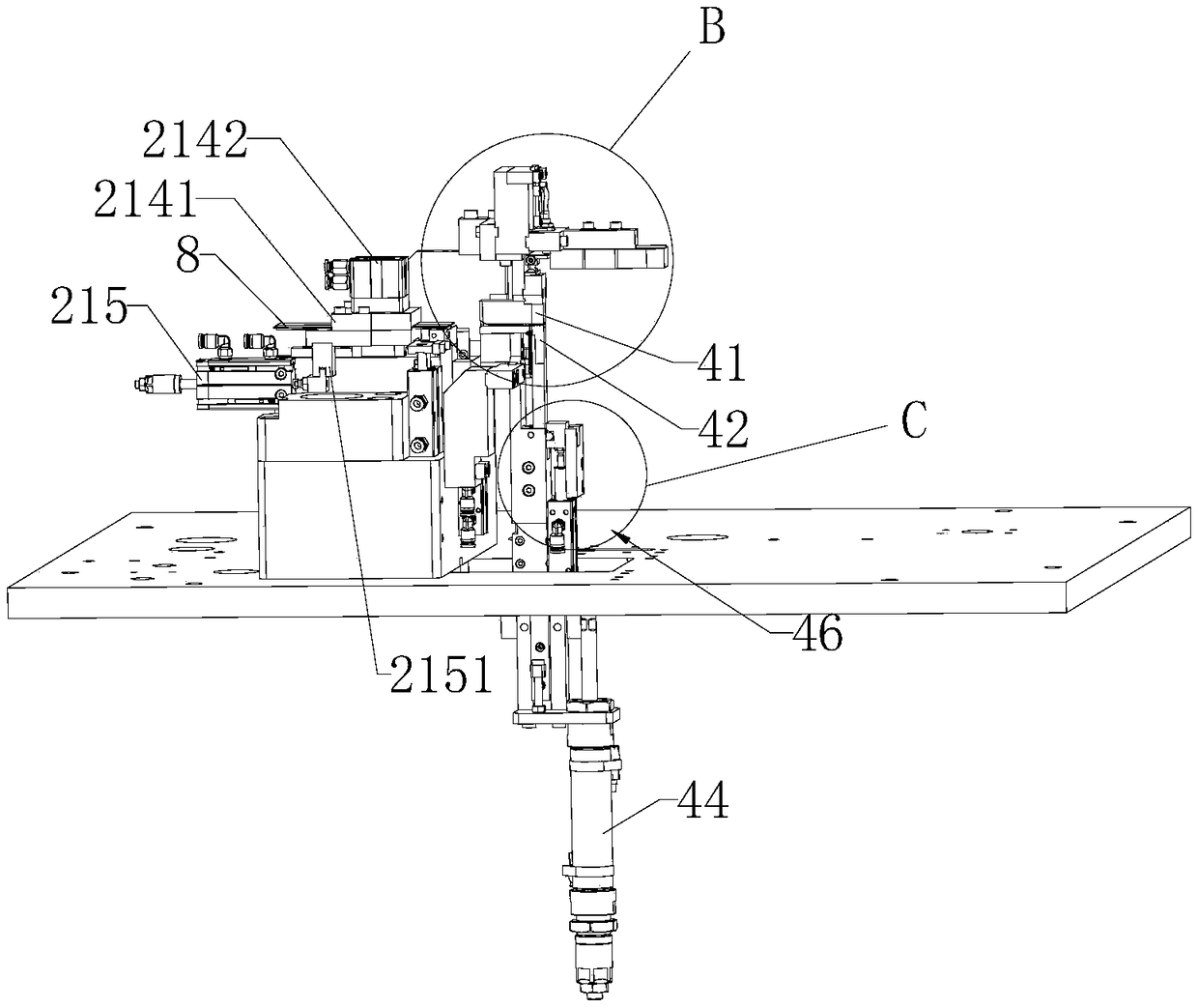

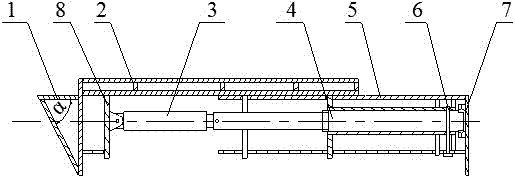

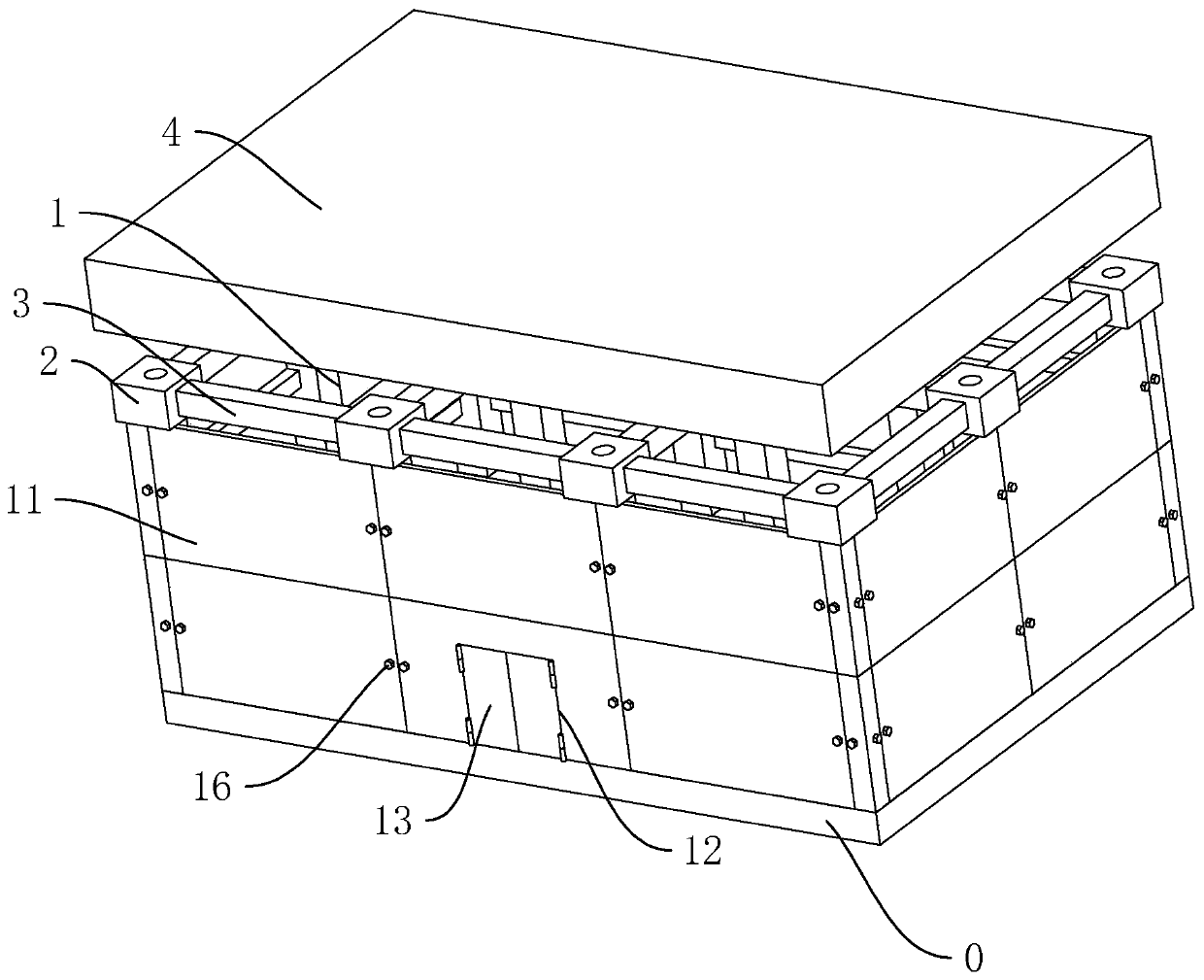

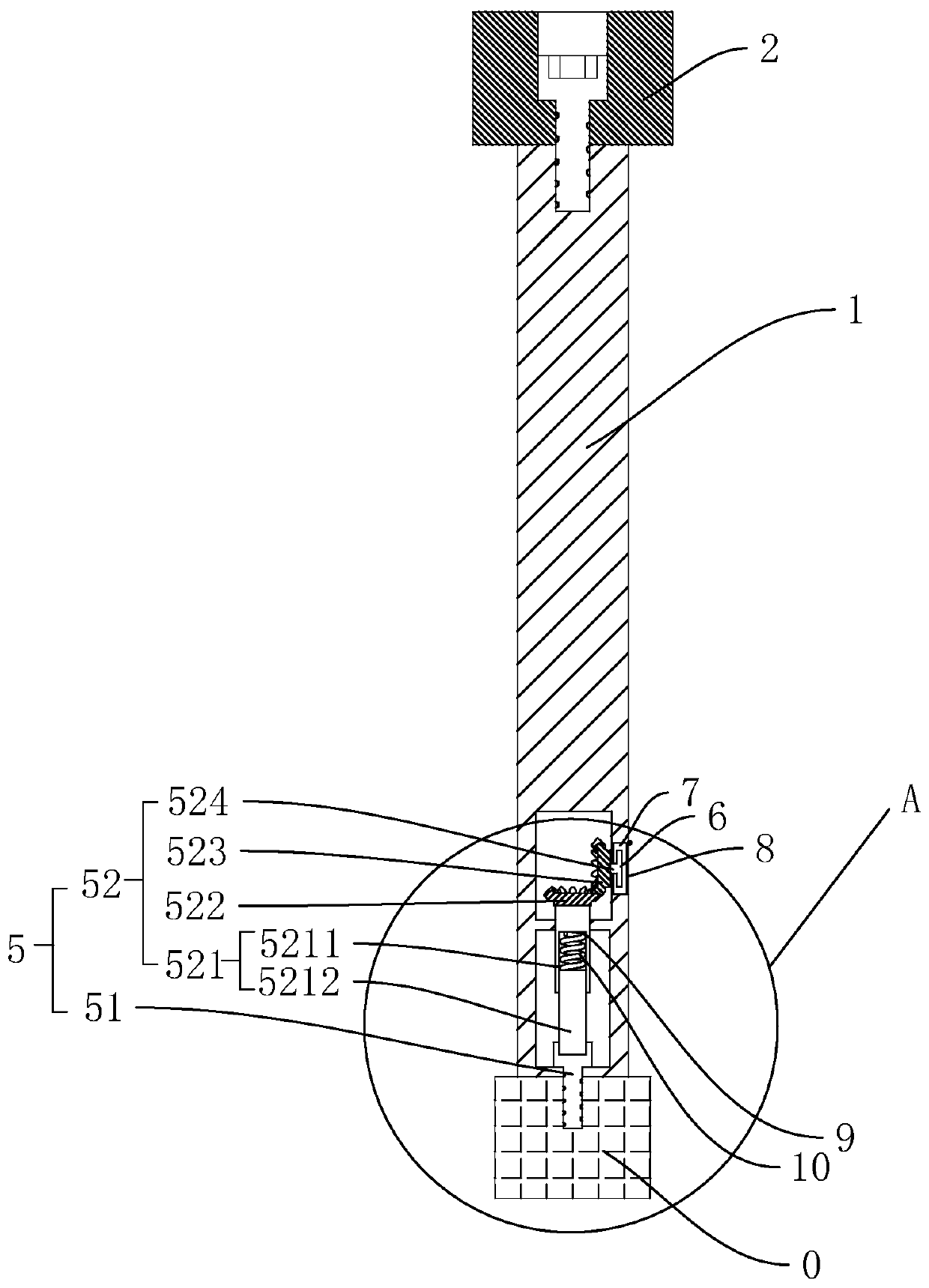

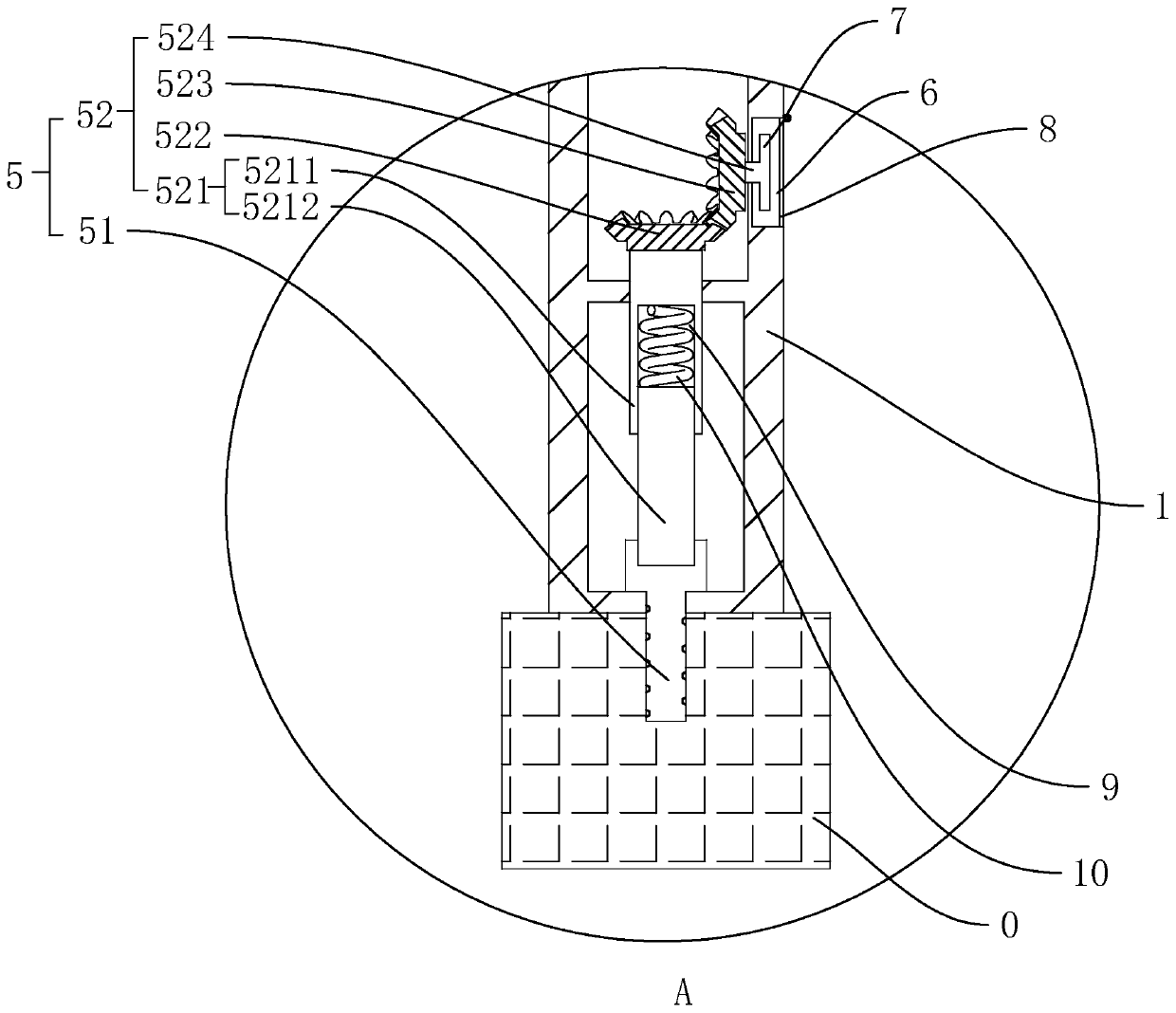

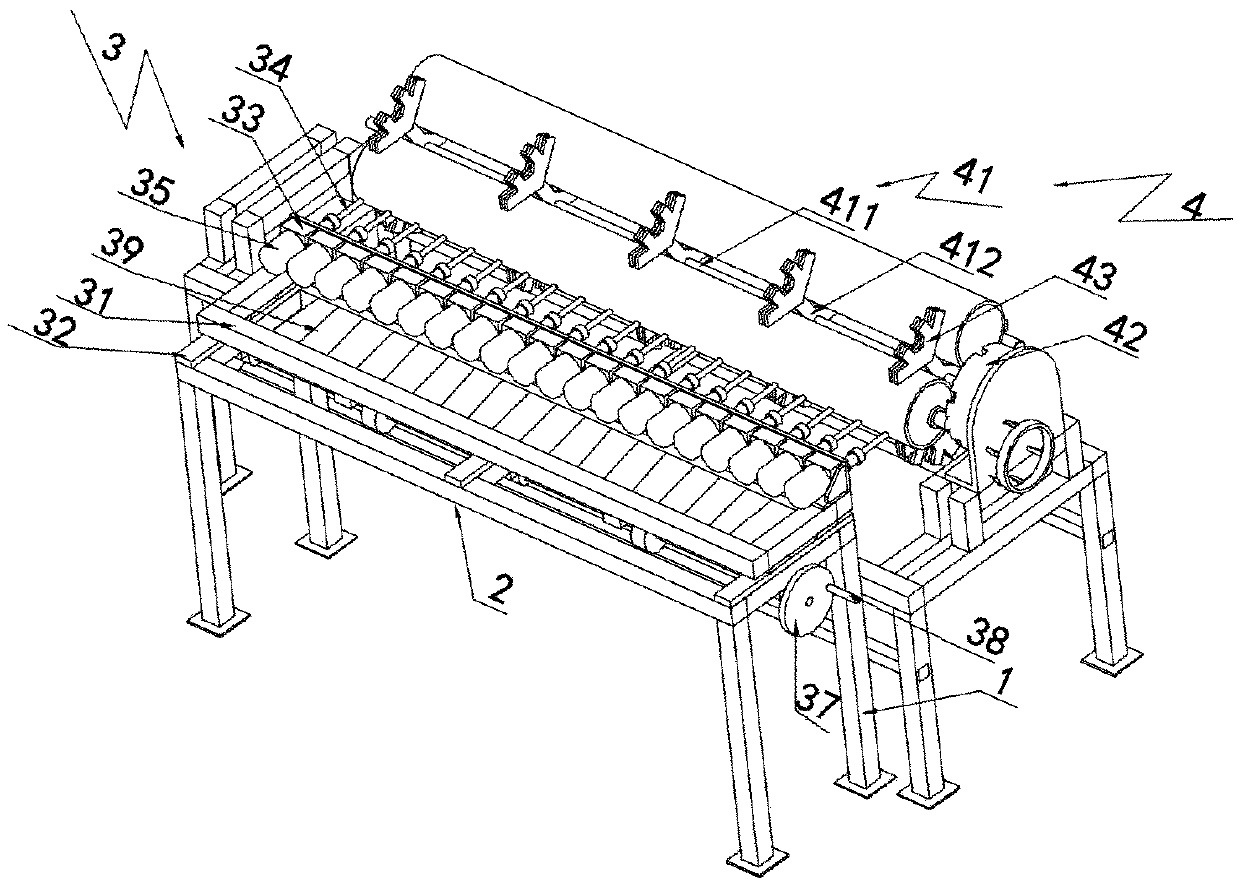

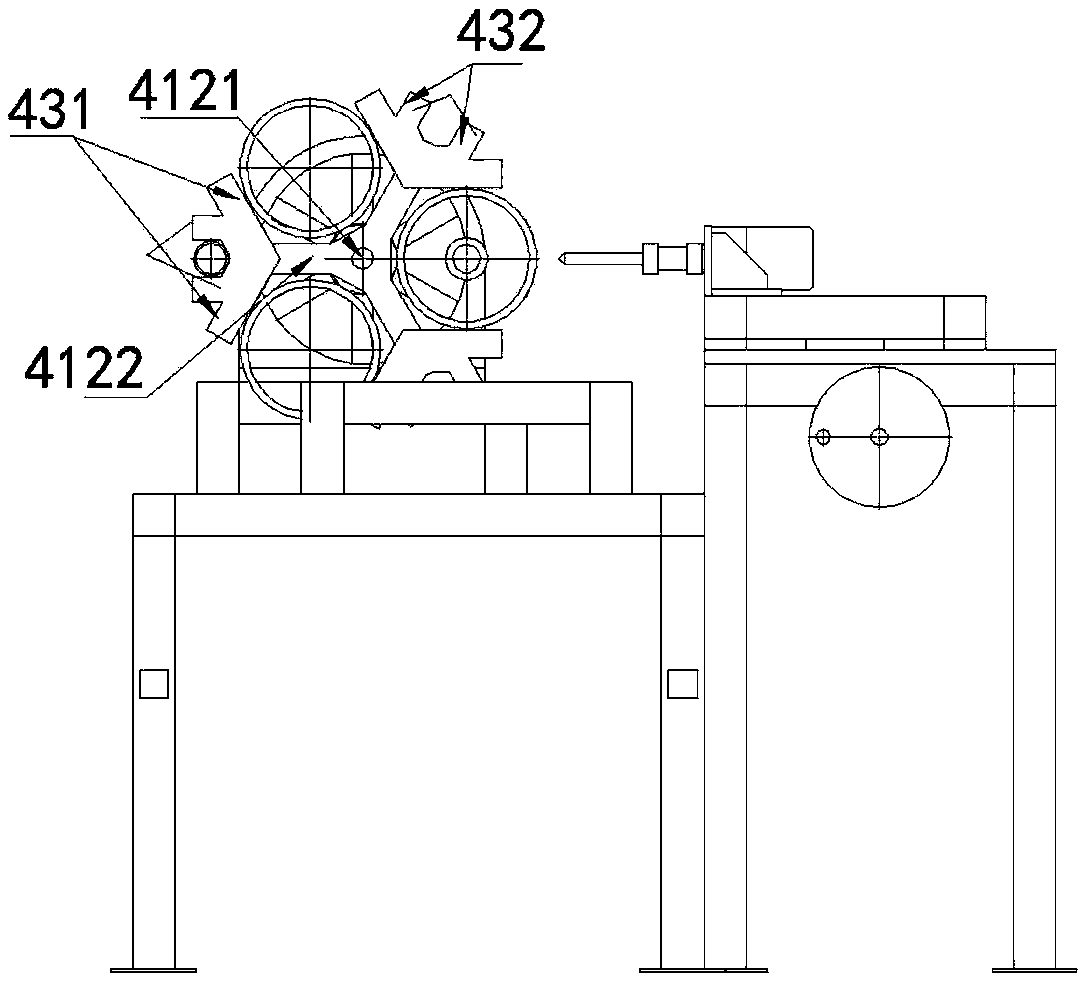

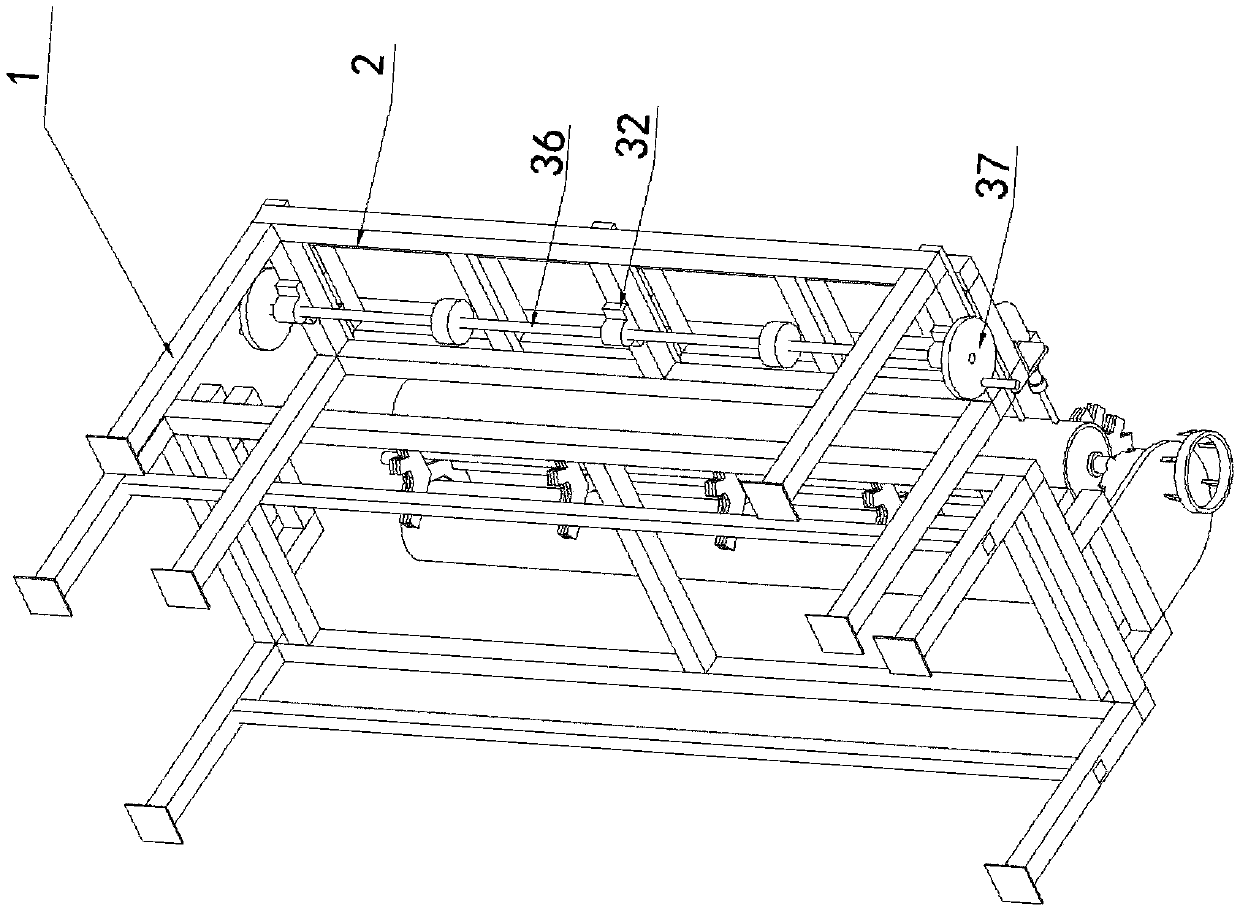

Slider penetrating device for zipper

The invention discloses a slider penetrating device for a zipper. According to the technical scheme, the slider penetrating device comprises a rack, feeding mechanisms, a slider penetrating mechanism,a cut-off mechanism and a chain dragging mechanical hand, wherein the feeding mechanisms comprise a chain belt feeding mechanism and a slider feeding mechanism, the slider feeding mechanism comprisesa vibrating plate and a feeding track, the rack is further provided with a single part pushing assembly, a horizontal conveying mechanism is arranged at the tail end of the lower end of the feeding track, the horizontal conveying mechanism comprises a horizontal sliding base, a material receiving plate and a horizontal drive mechanism, the horizontal sliding base is provided with a fixed block and a movable block, the fixed block, the movable block and the material receiving plate form a material receiving cavity for accommodating the slider, the material receiving cavity is arranged just opposite to a discharge hole of the feeding track, the slider is pushed into the material receiving cavity of the horizontal sliding base through the single part pushing assembly, the horizontal siding base is pushed towards the slider penetrating mechanism through the horizontal drive mechanism, thus the stability of the process of conveying the slider to the slider penetrating mechanism is increased, the conditions of blockage and material leak possibly caused by loading of the slider are reduced, and the use reliability of the device is improved.

Owner:广州市振宇拉链机械有限公司

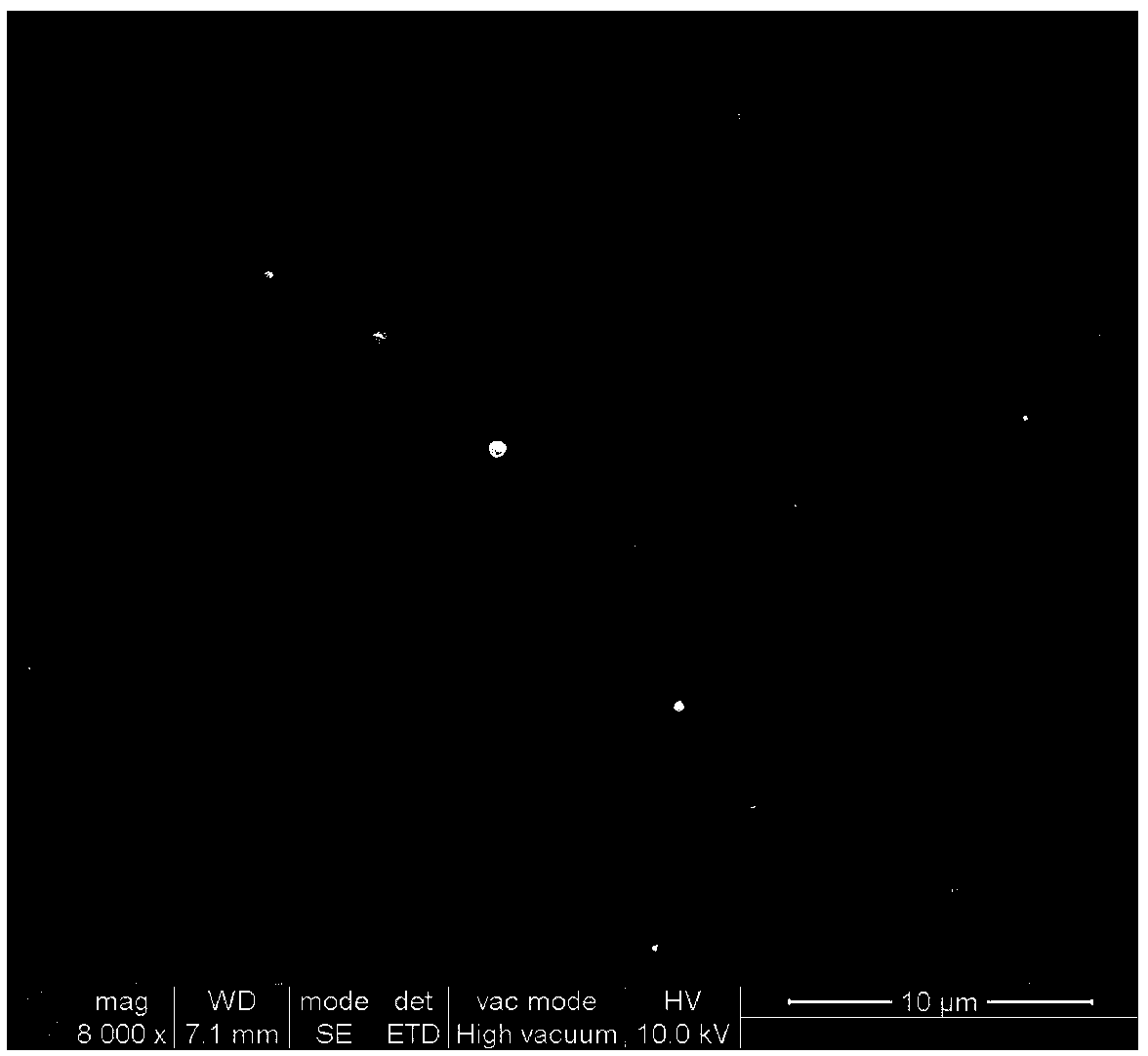

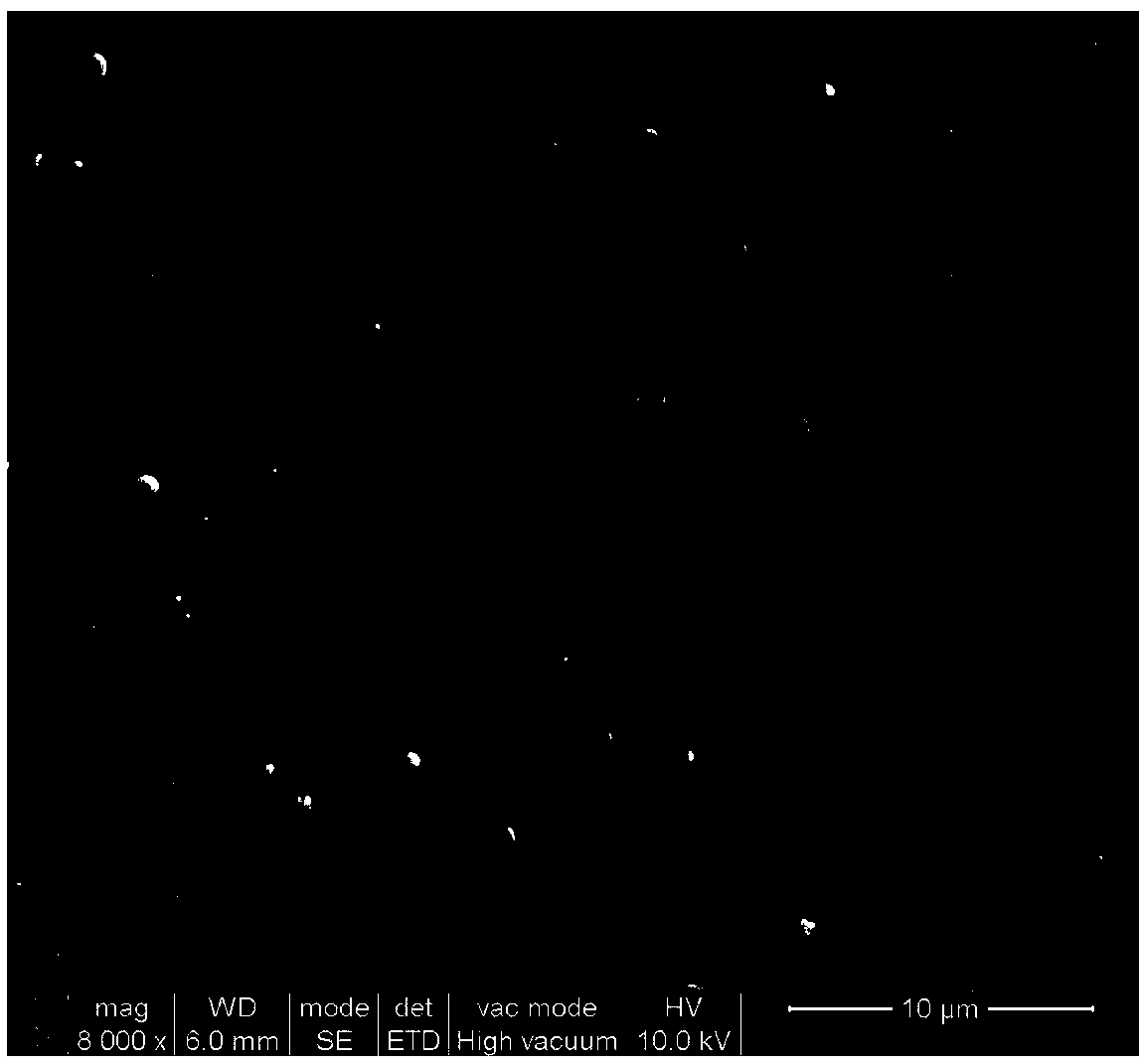

AlCrSiN nano-composite coating resistant to high temperature and abrasion and preparation method thereof

ActiveCN108796453AHigh hardnessImprove high temperature stabilityVacuum evaporation coatingSputtering coatingFilm baseUltimate tensile strength

The invention belongs to the technical field of coating preparation and particularly relates to an AlCrSiN nano-composite coating resistant to high temperature and abrasion and a preparation method thereof. According to the AlCrSiN nano-composite coating resistant to high temperature and abrasion and the preparation method thereof, a pulsed arc ion plating method is adopted; and a Cr interface implantation layer, a CrN transition layer and an AlCrSiN surface functional layer are sequentially deposited on the surface of a base body from bottom to top. Experimental results show that the AlCrSiNnano-composite coating obtained through the preparation method is excellent in high-temperature stability and abrasion resistance and has the advantages of being small in number of surface large particles, low in internal stress, high in film base bonding strength and the like; and the AlCrSiN nano-composite coating is applicable to surface protection of products such as mechanical parts, tools and molds.

Owner:GUANGDONG UNIV OF TECH

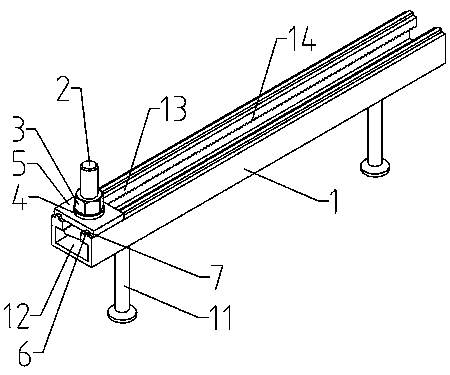

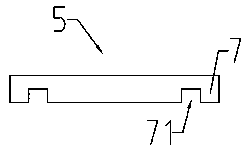

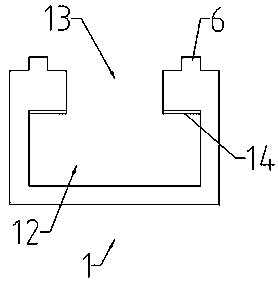

Anti-deformation pre-buried channel assembly

PendingCN111119239AImprove tensile propertiesIncreased shear capacityArtificial islandsBuilding constructionsClassical mechanicsEngineering

The invention relates to a connecting device special for being buried in concrete or masonry, in particular to an anti-deformation pre-buried channel assembly. The anti-deformation pre-buried channelassembly comprises a C-shaped pre-buried channel, a T-shaped bolt and a fastening nut, a gasket located between the fastening nut and the notch side of the C-shaped pre-buried channel is further arranged on the T-shaped bolt, first stop blocks extending towards the C-shaped pre-buried channel are arranged at the positions, corresponding to the two sides of the notch, of the side face, facing the C-shaped pre-buried channel, of the gasket, and second stop blocks extending towards the gasket are arranged at the positions, on the two sides of the notch, of the outer side face of the notch side ofthe C-shaped pre-buried channel; and the side, close to the notch, of the first stop blocks on each side is in stop fit with the side, away from the notch, of the corresponding second stop blocks, sothat the notch is prevented from deforming and opening in the directions of the two sides of the notch, the tensile and shear bearing capacity of the C-shaped pre-buried channel is enhanced, and theservice life of the C-shaped pre-buried channel is prolonged.

Owner:河南安诺尼建筑科技有限公司

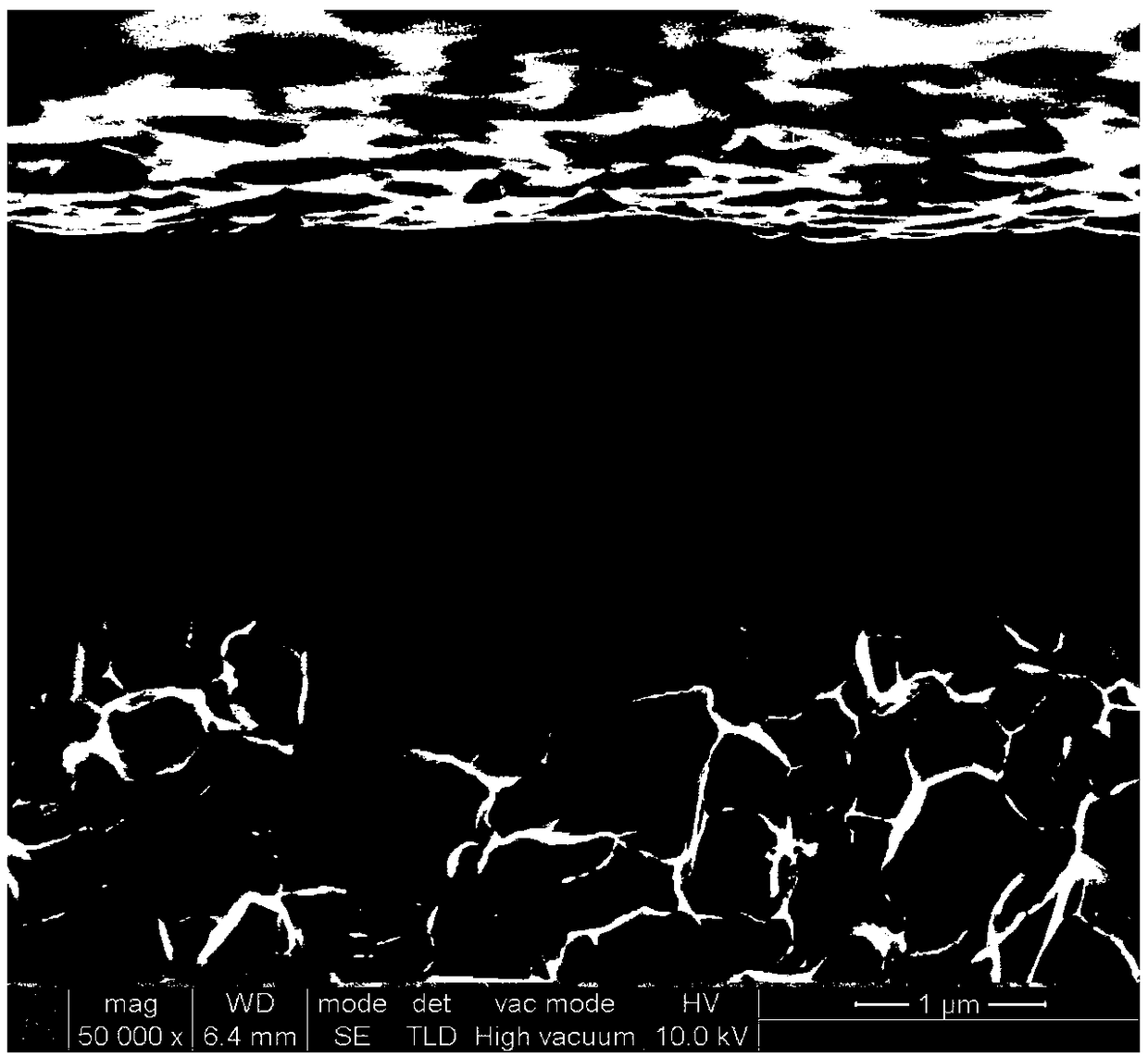

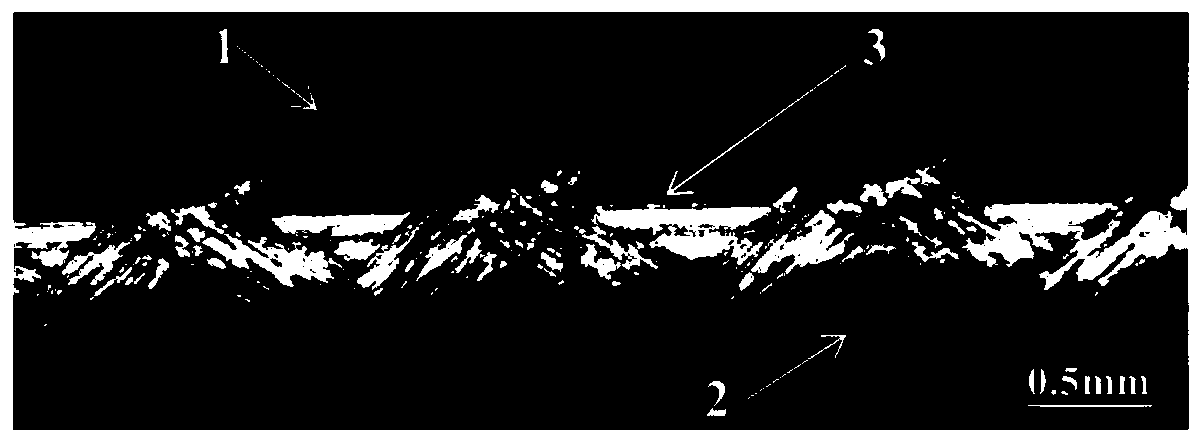

Novel composite metal fixed abrasive diamond rope and production process thereof

InactiveCN105459281AReduce mutual frictionLimit slipFine working devicesCoatingsCopper platingPre treatment

The invention relates to the technical field of diamond ropes, in particular to a novel composite metal fixed abrasive diamond rope. The novel composite metal fixed abrasive diamond rope comprises a core rope which is prepared by twisting a plurality of copper-plated steel wires and a soft polymer filling strip, wherein an attaching nickel layer for attaching diamond particles is deposited at the outer side of the core rope; the diamond particles are deposited on the attaching nickel layer on the surface of the core rope; and a packaging nickel layer for covering the diamond particles is deposited on the surfaces of the diamond particles. The invention further discloses a production process for the novel composite metal fixed abrasive diamond rope, wherein the production process comprises the following steps: compounding the core rope; carrying out surface pre-treatment; depositing the attaching nickel layer; attaching diamond; and depositing the packaging nickel layer. After the process is adopted, the core part of the core rope is free of a remarkable gap, so that a water-phase electrolyte solution is not remained in the space of the rope core, and therefore, corrosion is avoided; after the rope core is filled with soft stuffing, the diamond rope fracture risk is reduced; besides, by virtue of a buffer layer, slippage among steel wires is restricted, and coating is integrated, so that the coating fracture risk is reduced, and therefore, the line breakage risk in use is further reduced.

Owner:盛利维尔(常州)金属材料有限公司

Abrasion-resistant functional master batch for artificial yarns, method for preparing abrasion-resistant functional master batch and application thereof

ActiveCN106496911AImprove the immunityImprove plowing abilityMonocomponent polyolefin artificial filamentArtifical filament manufactureWater bathsFiber

The invention belongs to the technical field of novel materials, and particularly relates to abrasion-resistant functional master batch for artificial yarns and a method for preparing the abrasion-resistant functional master batch. The abrasion-resistant functional master batch comprises grafting materials and catalyst materials. The grafting materials comprise, by weight, 70-99 parts of polyethylene resin, 0.01-10 parts of initiators, 1-10 parts of silane coupling agents and 0.01-10 parts of antioxidants, and the catalyst materials comprise, by weight, 80-99 parts of polyethylene resin, 0.1-10 parts of catalysts and 0.1-10 parts of antioxidants. The method includes preparing the grating materials and the catalyst materials by the aid of two-step processes; proportionally granulating the grafting materials and the catalyst materials by the aid of screw extruders; soaking granules in water bath at the certain temperatures for a certain time; drying the granules to obtain the abrasion-resistant functional master batch. The abrasion-resistant functional master batch and the method have the advantages that the abrasion-resistant functional master batch prepared by the aid of the method can be added into yarn matrixes, and accordingly the abrasion resistance, the strength, the tear resistance, the fatigue resistance and the like of yarn fibers can be obviously improved.

Owner:EAST CHINA UNIV OF SCI & TECH

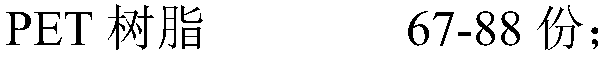

Injection molding grade glass fiber reinforced PET (Polyethylene Terephthalate) micro-foamed composite material and preparation method thereof

The invention discloses an injection molding grade glass fiber reinforced PET (Polyethylene Terephthalate) micro-foamed composite material and a preparation method thereof. The composite material comprises 96-98wt% of a PET composite material and the balance of a chemical foaming agent, wherein the PET composite material comprises PET resin, a toughening agent, a cross-linking agent, modified glass fiber, an antioxidant, a lubricant and other aids. According to the invention, carbimide propyl triethoxysilane is adopted to modify the surface of alkali short cut glass fiber strands so as to enable the surface of the glass fiber strands to be endowed with active groups, the alkali short cut glass fiber strands are added into the PET resin to implement a chemical reaction with terminal hydroxyl, then a coupling function is achieved, the glass fiber dispersion is promoted, the fibers are distributed in a staggered manner to form a three-dimension net, a chain segment physical cross-linkingfunction is enhanced, and the sliding of a molecular chain is limited, so that the melt viscosity of a PET chain segment can be increased, and the mechanical strength of the composite material can beimproved.

Owner:ORINKO NEW MATERIAL CO LTD

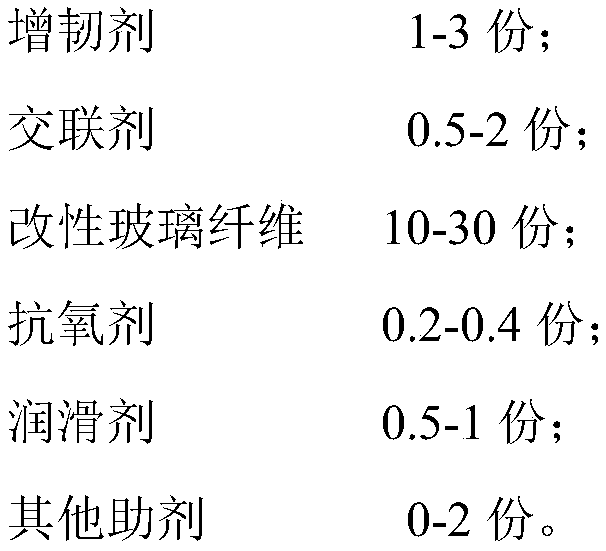

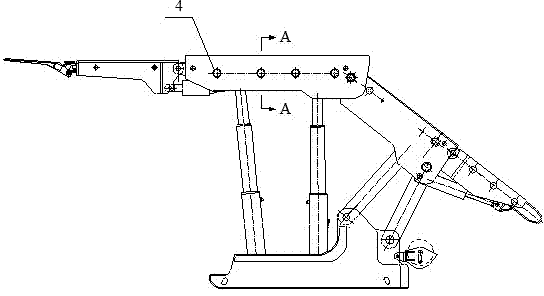

Triangular area hydraulic support top protection device on upper end of large-inclination-angle working surface

The invention discloses a triangular area hydraulic support top protection device on the upper end of a large-inclination-angle working surface. The triangular area hydraulic support top protection device comprises a triangular area hydraulic support, wherein a top beam of the triangular area hydraulic support is provided with double-action side pushing jacks at intervals, the maximum stroke of the double-action side pushing jacks is 0.3-0.5 times the width of the hydraulic support, a beam body of the top beam is provided with a side protection board, a base of each double-action side pushing jack is fixedly arranged on the side protection board, the beam body is provided with a top beam movable side protection board which is of a box body structure, the width of the top beam movable side protection board is equal to that of the hydraulic support, a push rod of each double-action side pushing jack is connected with a connecting rod, the end of each connecting rod is fixedly arranged on an inner side board of the top beam movable side protection board, the outer side of the top beam movable side protection board is provided with a triangular box body of which an top angle is alpha, and the sum of the top angle alpha and an inclination angle of a working surface is equal to 90 degrees. The triangular area hydraulic support top protection device disclosed by the invention is suitable for the supporting and protecting of a top board in a triangular area exposed on the upper end of the large-inclination-angle working surface, not only can the stability of an end support be effectively controlled, but also a person can be prevented from being damaged due to the falling off of waste rocks on the top board exposed in the triangular area, and the safety of a worker under the triangular support can be ensured.

Owner:CHINA UNIV OF MINING & TECH +2

Hollow porous absorbable suture line and preparation method

The invention provides a hollow porous absorbable suture line and a preparation method thereof. Non-absorbable woven yarn and absorbable axial yarn are prepared into the hollow porous absorbable suture line through the two-dimensional three-axial weaving technology and the thermal treatment technology. The preparation method comprises the steps that firstly, woven yarn and axial yarn are performedon the surface of a lining tube, a suture line with the porous surface is obtained, and the pore size is adjustable in the axial direction; then, due to the thermal treatment technology, the axial yarn is partially fused to fix a weaving point of the woven yarn; finally, the lining tube is removed, and the hollow porous suture line of the stable structure is obtained. The suture line is partiallyabsorbable, mechanical supporting can be ensured, and the non-absorbable ratio can be lowered; due to the hollow porous structure, tissue ingrowth is facilitated, tissue regeneration is promoted, when the suture line is in use, the stress of the suture line is in a ribbon shape, and cutting of tissue is reduced. By adopting the integrated forming technology by combining weaving and thermal setting, no welding, bonding and other post-treatment technologies are needed, the procedures are simple, and processing is convenient.

Owner:DONGHUA UNIV

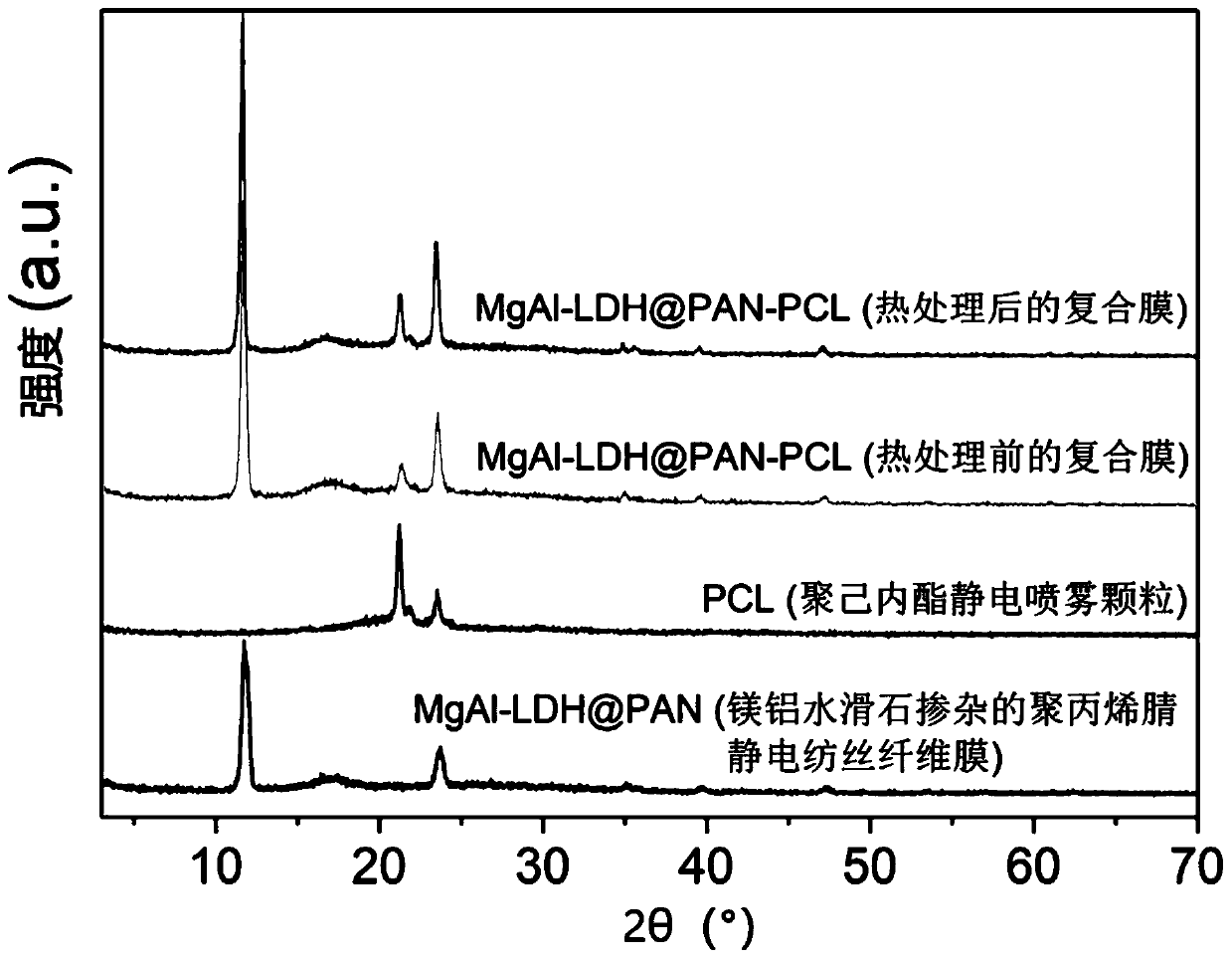

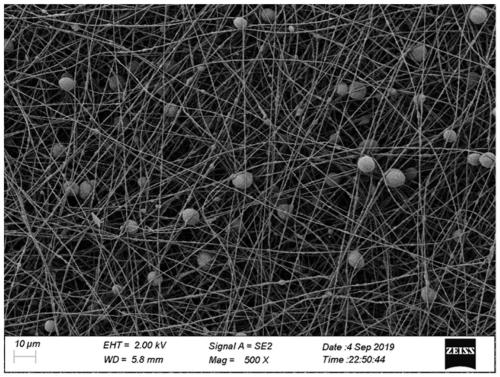

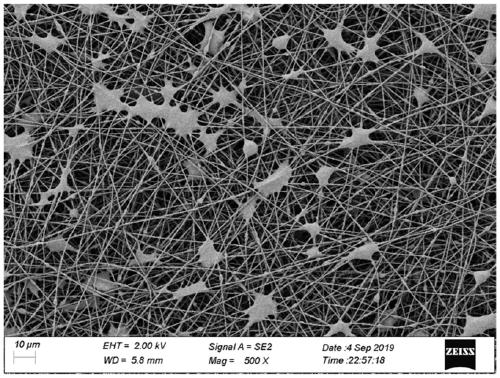

Structure-enhanced hydrotalcite-immobilized composite fiber membrane and preparation method and application thereof

The embodiment of the invention relates to the field of membrane materials, in particular to a structure-enhanced hydrotalcite-immobilized composite fiber membrane and a preparation method and application thereof. The embodiment of the invention provides the preparation method of the composite fiber membrane. The preparation method comprises the following steps: respectively preparing an electrostatic spinning solution and an electrostatic spraying solution, carrying out electrostatic spinning and electrostatic spraying at the same time, collecting electrostatic spinning fibers obtained through electrostatic spinning and electrostatic spraying particles obtained through electrostatic spraying in the same receiver so thata composite fiber membrane is obtained, drying the composite fiber membrane, and carrying out heat treatment on the dried composite fiber membrane. The electrostatic spinning technology and the electrostatic spraying technology are carried out at the same time, particles obtained through electrostatic spraying become nodes of fixed nanofibers after heat treatment so as to limit movement of the nanofibers, the integrity and the mechanical strength of the fiber membrane are improved, the wind pressure resistance is enhanced accordingly, and the application range of the fiber membrane obtained through electrostatic spinning is widened.

Owner:BEIJING UNIV OF CHEM TECH

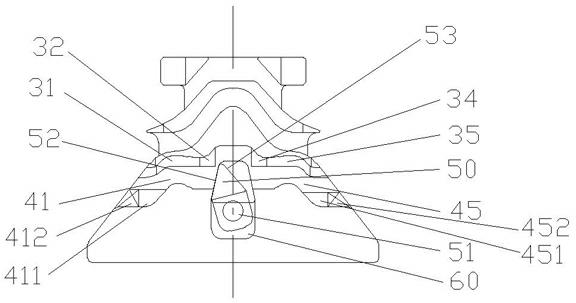

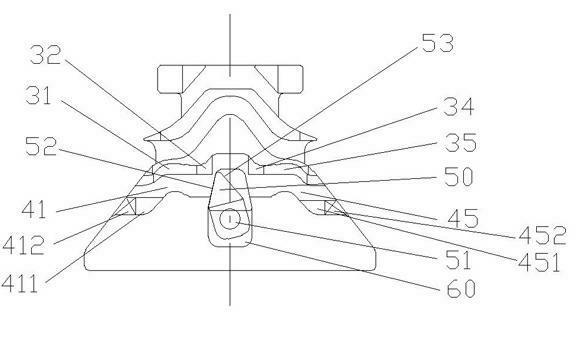

Middle cam of computerized flat knitting machine

InactiveCN102517781AImprove sliding effectPrevent Yi from slipping down from the third left and right chutesWeft knittingEngineeringCam

The invention discloses a middle cam of a computerized flat knitting machine, which comprises a third rail and a fourth rail used for tucking and receiving, wherein the third rail and the fourth rail are splayed and laterally pass through a body. Middles of the two rails form a middle groove, a limiting groove is arranged right below the middle groove, and a swing cam is arranged in the limiting groove and positioned by a center hole which is arranged on the center line of the body. A fourth left inclined groove, the left slope of the swing cam, a third right slope and a third right inclined groove form a one-way needle passing rail c, and other portions form a one-way needle passing rail d correspondingly. A step is arranged on the inner lower portion of the fourth left inclined groove so that an upper inner space of the fourth left inclined groove allows a combined needle butt to slide out, and the height of the step is smaller than the depth of the fourth left inclined groove. The step and a wide inlet of the fourth left inclined groove are in connection through a slope. Slipping of the needle butt is limited while sliding out is convenient during knitting, sliding in of the needle butt is facilitated, sliding of the needle can be more smooth, and operation of the computerized flat knitting machine can be more stable.

Owner:陶春明

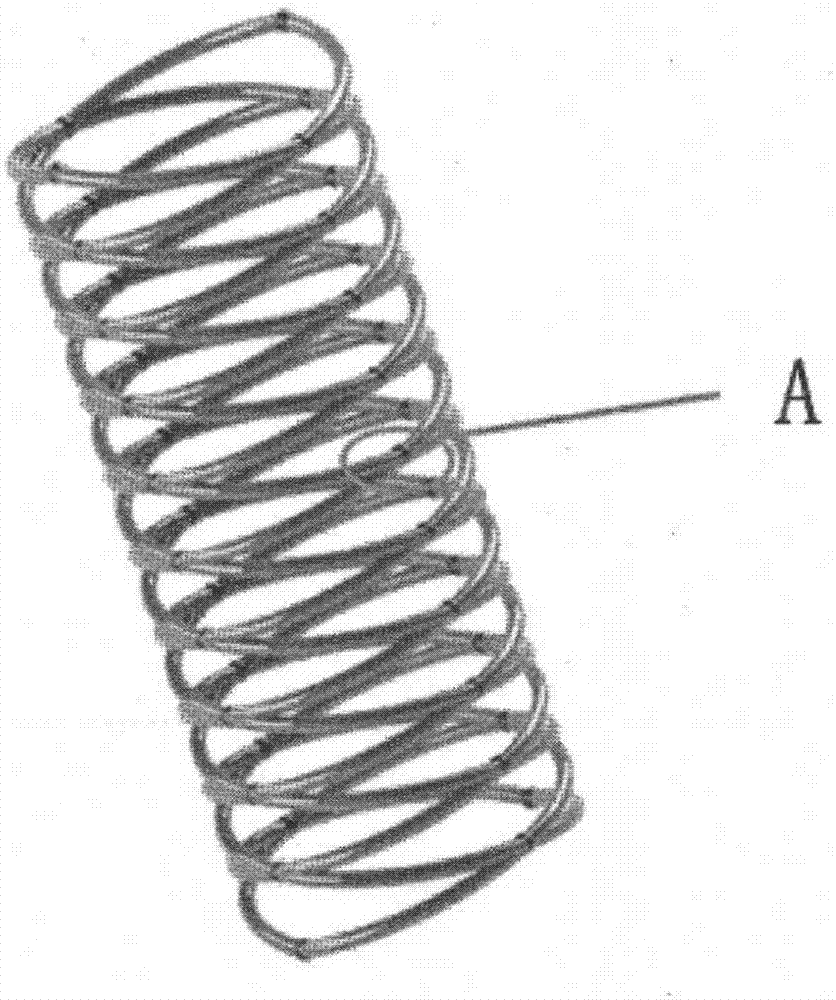

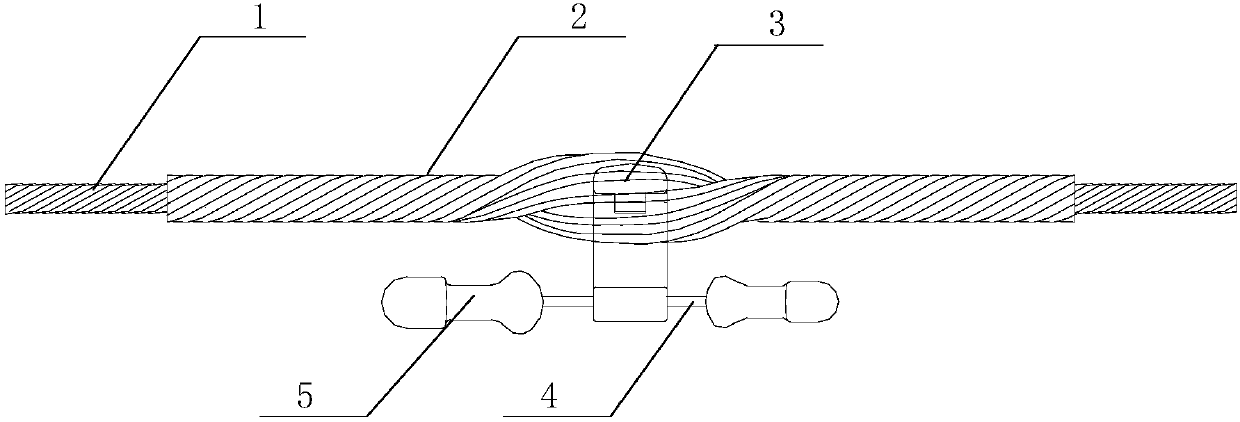

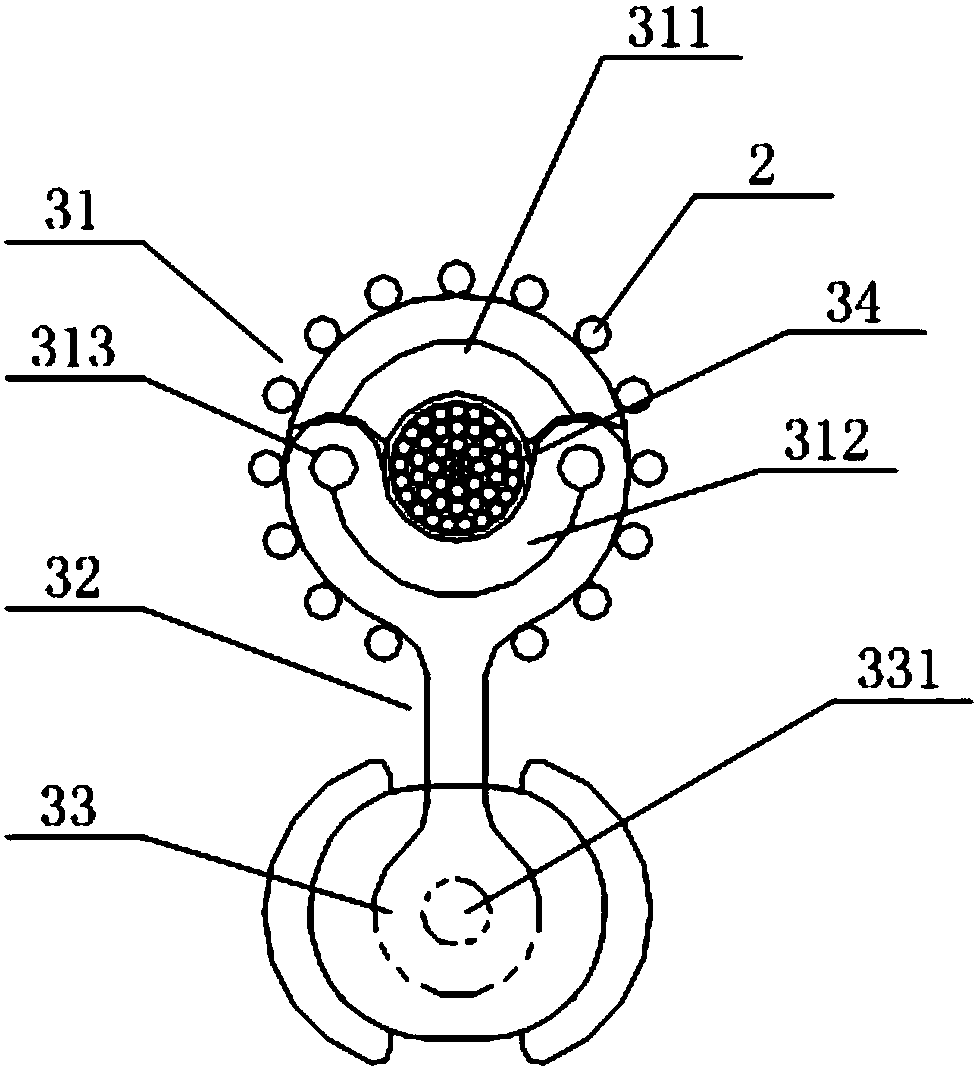

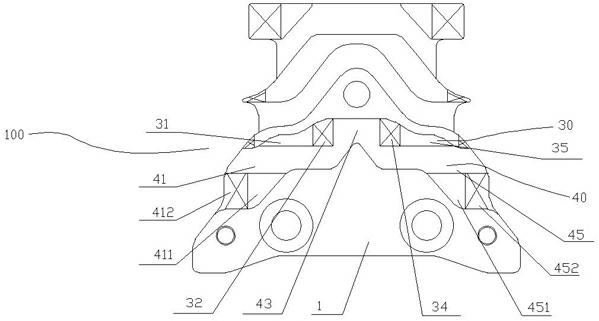

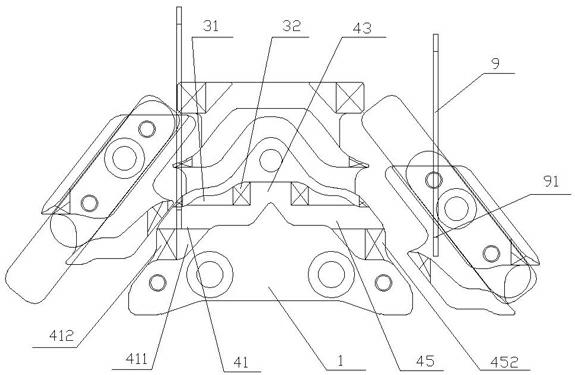

Anti-slip damper with all-clad pre-twisted wires

InactiveCN107689613AStable and effective gripSolve the phenomenon that is prone to slippageDevices for damping mechanical oscillationsEngineeringMechanical engineering

The invention provides an anti-slip damper with all-clad pre-twisted wires. The damper comprises the all-clad pre-twisted wires winding around a wire, a wire clamp mechanism connected with the wire, and a steel stranded wire with damper heads at both ends. The wire clamp mechanism comprises a clamping part for holding the wire, a fixing part for arranging the steel stranded wire, and a connectingpart for connecting the clamping part and the fixing part. The damper is fixed on the wire through the wire clamp mechanism, and the clamping part of the wire clamp mechanism is provided with the all-clad pre-twisted wires, so that slip of the damper on the wire is restricted, and it is avoided that the damper rotates and slips in the wire direction or the twisting direction of the pre-twisted wires during the long-time use process or under the action of strong vibration.

Owner:STATE GRID CORP OF CHINA +1

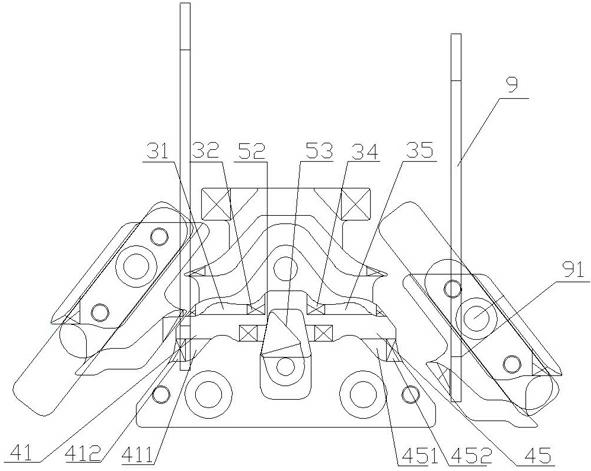

Middle guide triangular part of computerized flat knitting machine

InactiveCN102517780APrevent easy slipping from left and right upper chutePrevent problems that are not slipping outWeft knittingEngineering

The invention discloses a middle guide triangular part of a computerized flat knitting machine, which comprises a eudipleural body, a left stitch connecting track and a right stitch connecting track. The left stitch connecting track comprises a left lower chute and a right upper chute. The right stitch connecting track comprises a right lower chute and a left upper chute. A step is arranged at the lower portion in the left lower chute to enable a space of the upper portion in the left lower chute to be used for needle butts of combined needles to slip out right, and the height of the step is smaller than the depth of the left lower chute. The step and the wide inlet position of the left lower chute form slope transition. The right lower chute and the left lower chute are symmetrical bilaterally. By limiting the step of the middle guide triangular part and arranging a slope, when stitch-connecting weaving is performed, the slipping-off of the needle butts is limited so as to facilitate slipping-out, slipping-into of the needle butts is facilitated, and accordingly running of the computerized flat knitting machine is stable.

Owner:陶春明

Display shed and mounting method thereof

ActiveCN110952806AReduce the probability of accidentsEliminate potential safety hazardsTents/canopiesSpecial buildingStructural engineeringMechanical engineering

The invention relates to a display shed. The display shed comprises a plurality of stand columns, wherein the stand columns are arranged in a rectangular shape and placed on the ground; connecting blocks are mounted on the sides, away from the ground, of the stand columns; connecting rods are mounted between the connecting blocks of the adjacent stand columns; shed cloth fixedly covers the sides,away from the stand columns, of the connecting blocks; fixing mechanisms are arranged between the stand columns and the ground; each fixing mechanism comprises a fixing bolt and a driving assembly; the fixing bolts are mounted on the stand columns and are in threaded connection with the interior of the ground; and the driving assemblies are mounted on the stand columns and used for driving the fixing bolts to rotate, and therefore the fixing bolts are disassembled and assembled on the ground, and the stand columns are disassembled and assembled. The display shed has the advantages that the stand columns can be fixed, the display shed is prevented from being scraped when strong wind blows, the accident occurrence probability is reduced, and potential safety hazards are eliminated.

Owner:上海满江洪会展服务有限公司

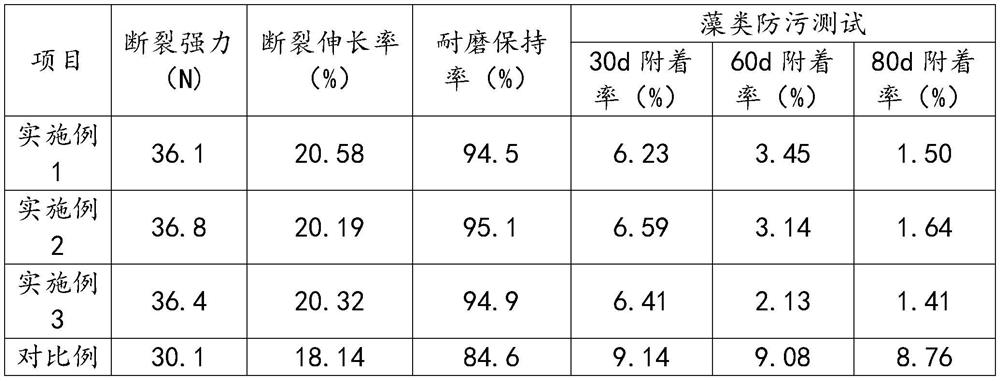

Polyvinyl fishing net composite material and preparation method thereof

PendingCN112341805AImprove anti-aging propertiesImprove mechanical propertiesMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberHalloysite

The invention discloses a polyvinyl fishing net composite material, which is prepared from the following raw materials in parts by weight: 200-300 parts of polyamide slices, 20-30 parts of modified polyethylene fibers, 10-15 parts of dicumyl peroxide, 5-10 parts of antifouling filler, 1-3 parts of compatilizer and 0.5-1 part of anti-aging agent. The invention also discloses a preparation method ofthe polyethylene-based fishing net composite material, which comprises the following steps: uniformly mixing and stirring the raw materials in a reaction kettle, and carrying out extrusion granulation in a double-screw extruder to obtain the polyethylene-based fishing net composite material. By utilizing the special physical and chemical properties of graphene and halloysite, the composite material has the characteristics of favorable mechanical properties, high stain resistance and aging resistance.

Owner:JIESHOU XINGLONG FISHING TACKLE

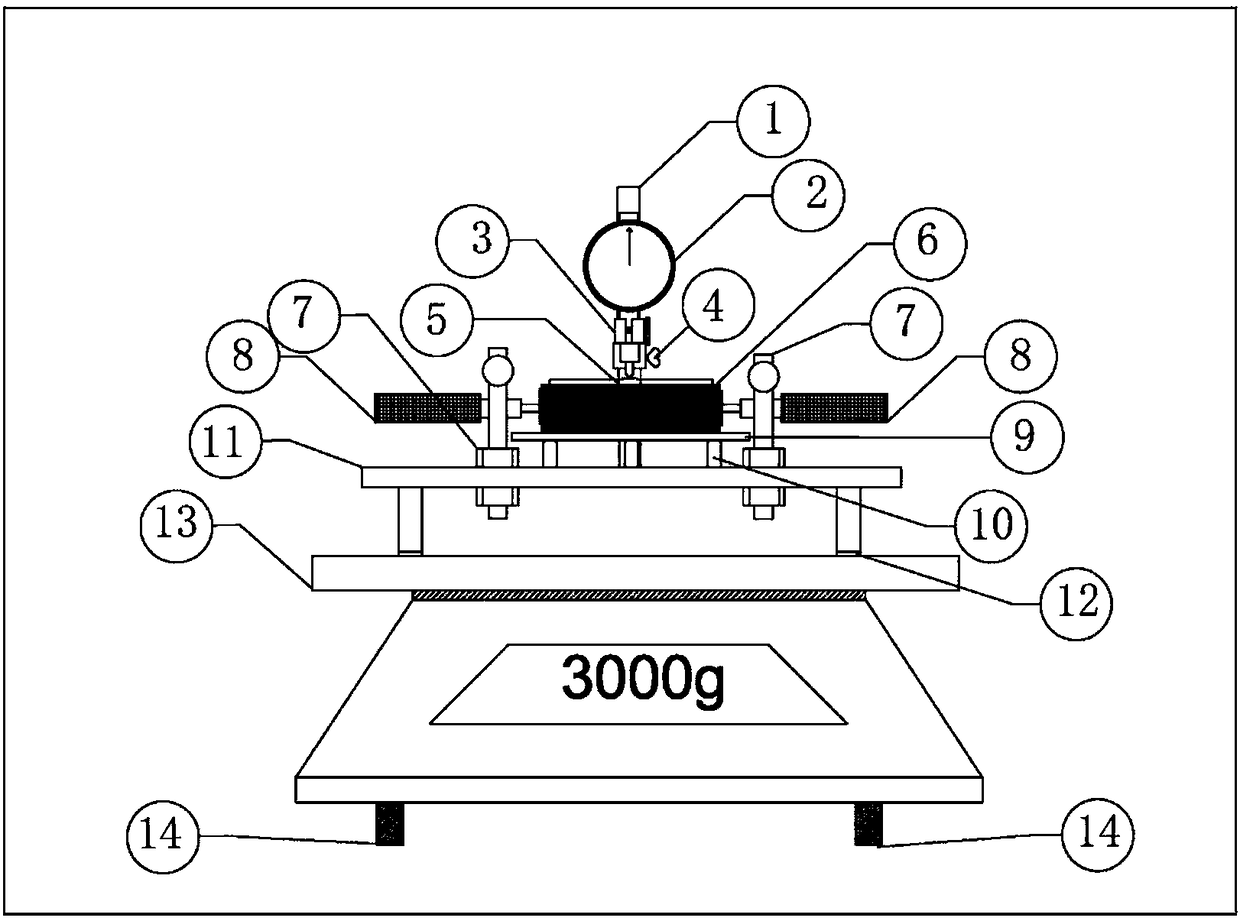

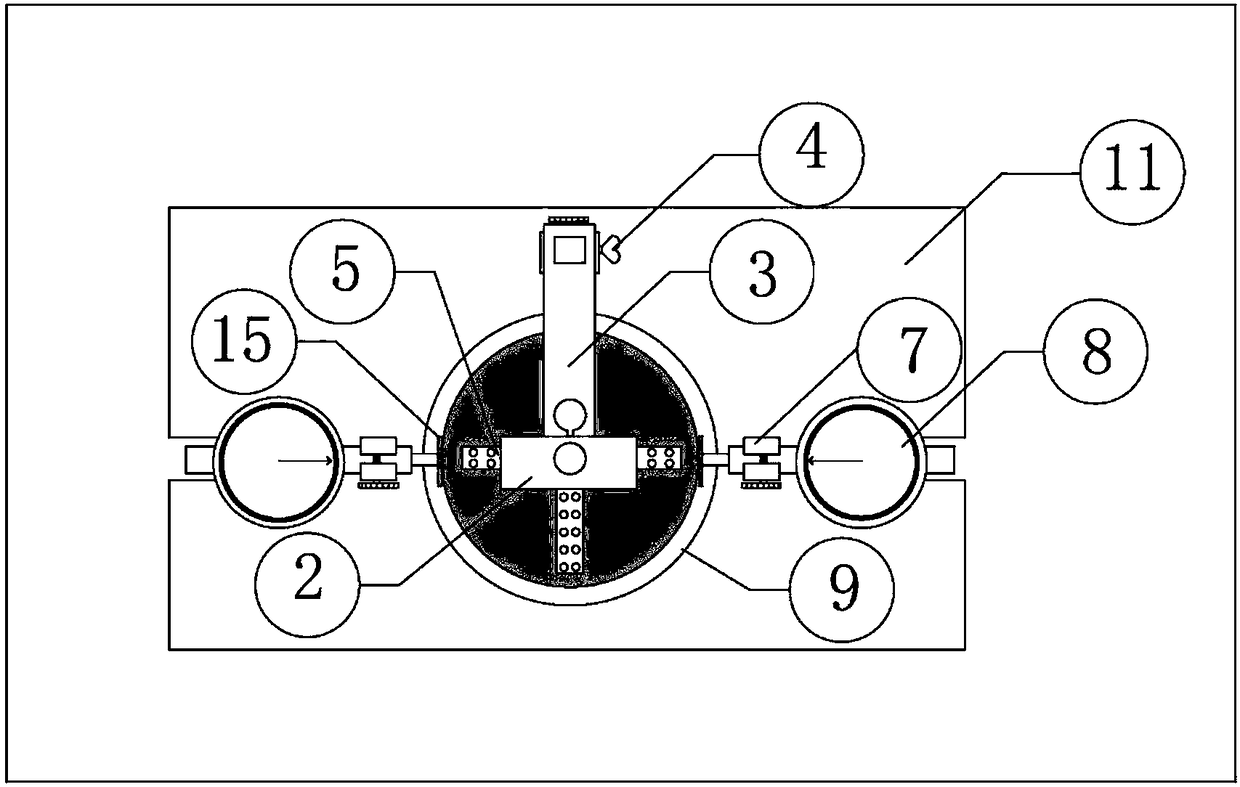

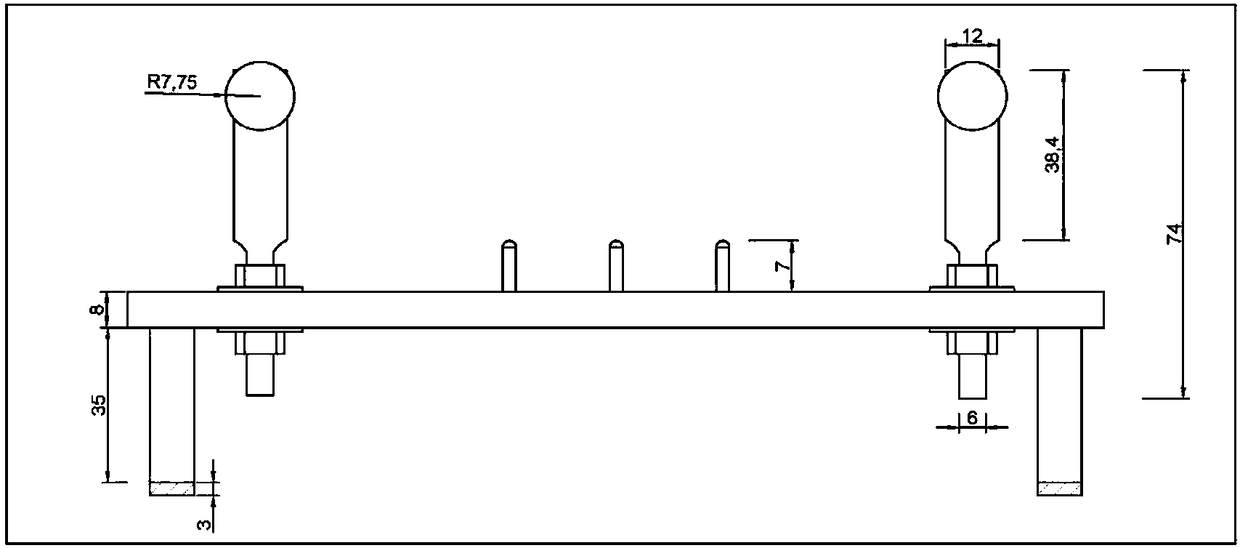

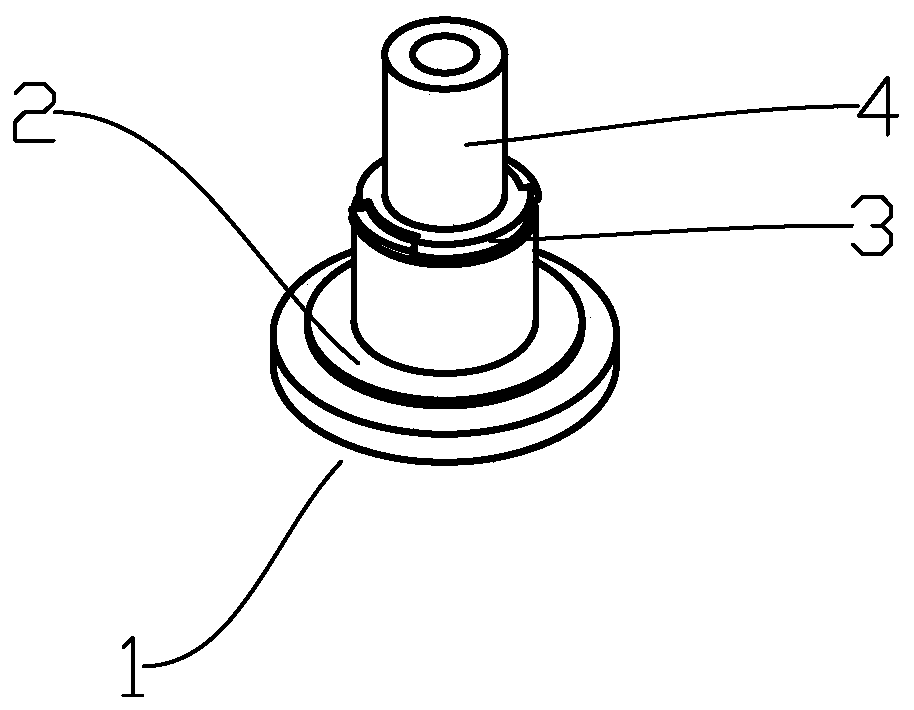

Novel anti-disturbance shrinkage test device

PendingCN108508188AGuaranteed accuracyGuaranteed reliabilityEarth material testingTest sampleMoisture

The invention discloses a novel anti-disturbance shrinkage test device. The device comprises a mass measuring device and a deformation measuring device; the deformation measuring device is composed ofthree gauges, a perforated plate, a bracket, a measuring plate, spacers and a base, wherein two gauges are fixed on the base, and the other one gauge is mounted on the bracket; the mass measuring device is a flat electronic scale the precision of which reaches 0.01 g, and the deformation measuring device is placed on the mass measuring device. The novel anti-disturbance shrinkage test device cancollect the moisture content and volume parameters of a test sample in a shrinkage test in real time; the effect of resisting external-force disturbance is achieved through the anti-vibration rubber spacers, the perforated plate with a groove and the novel connection bracket, and therefore the test has high measuring precision. The device is simple in structure, easy to operate and very convenientto assemble and disassemble.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

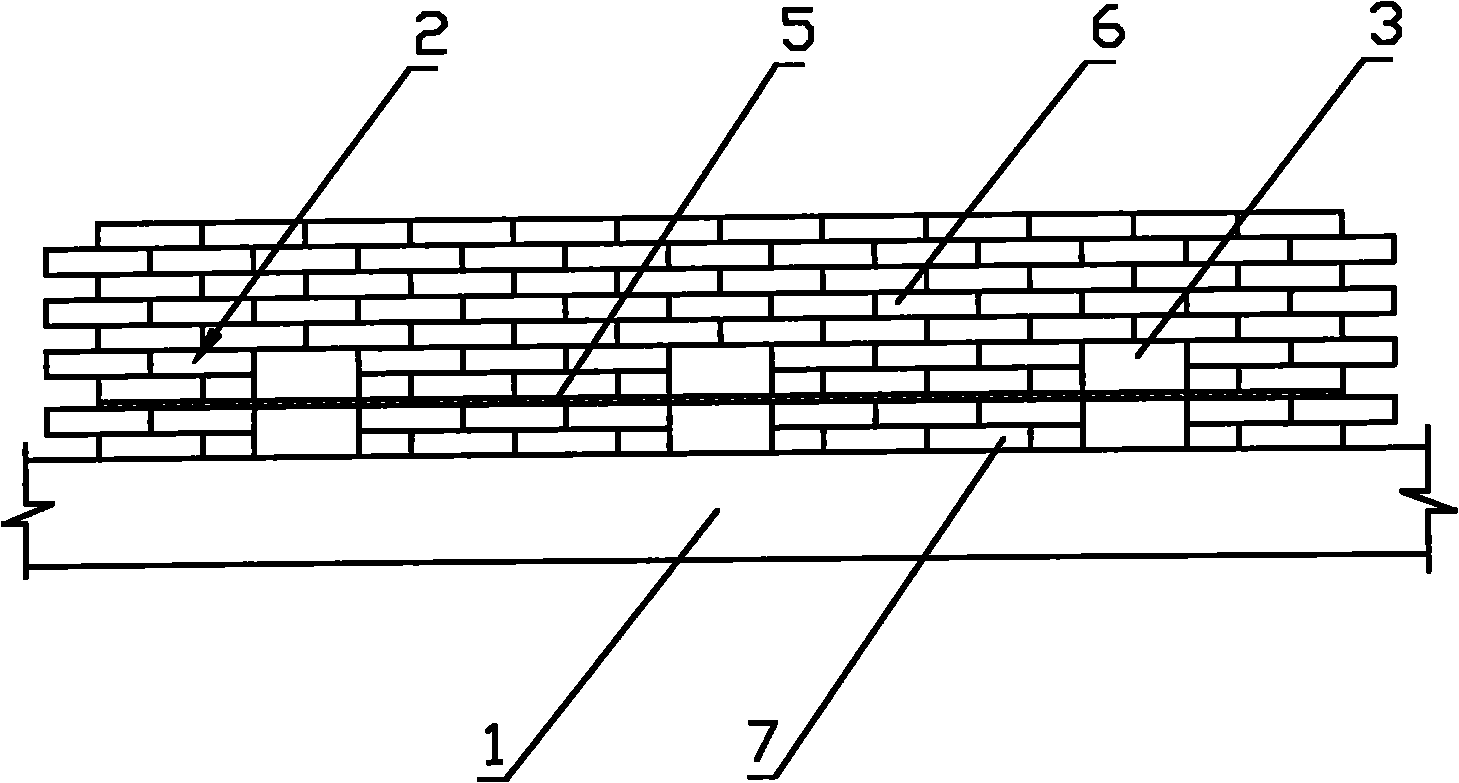

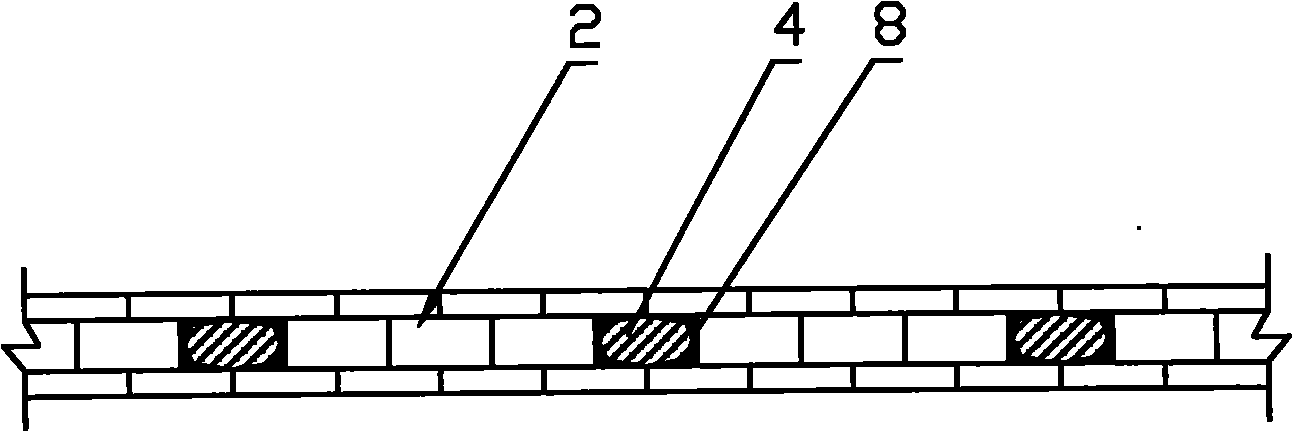

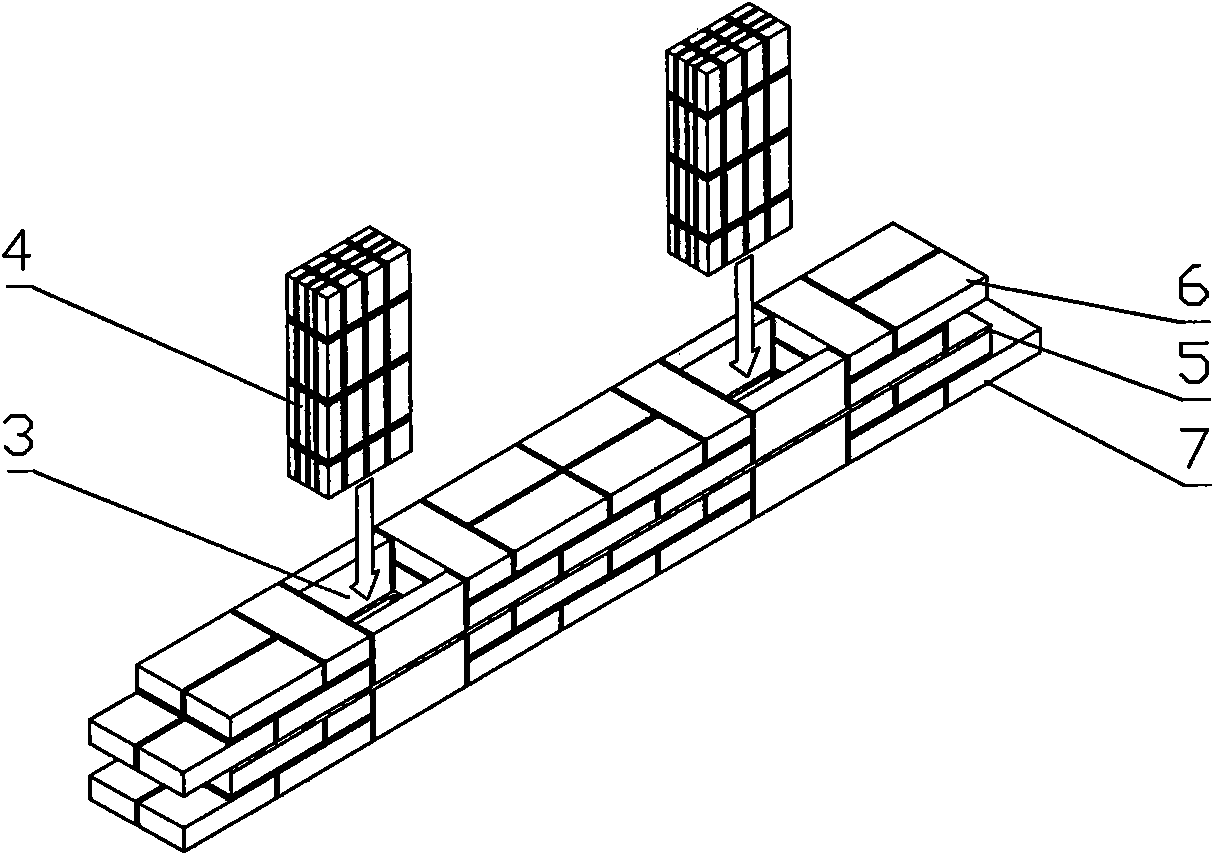

Energy dissipation and shock absorption building with bound rubber beams

InactiveCN101839083AGuaranteed normal use of functional requirementsPlay a shock absorbing roleProtective buildings/sheltersLower gradeEngineering

The invention discloses an energy dissipation and shock absorption building with bound rubber beams, comprising a diquanliang (DQL) and a wall body constructed on the DQL, wherein a plurality of rubber beam installation holes are arranged along the same horizontal height in the wall body at equal intervals, rubber beams are arranged in the rubber beam installation holes, the wall body is divided into an upper wall body and a lower wall body by a low grade cement mortar layer horizontally paved therein, and the low grade cement mortar layer is at the same horizontal height with the middle part of the rubber beams. The wall bodies are subjected to slippage in the low grade cement mortar layer and the built-in bound rubber beams are in elastic-plastic shear deformation under the action of a large earthquake, thus realizing dissipation of earthquake energy transmitted to an upper structure from a foundation, weakening the earthquake energy transmitted to the upper structure, and further playing a shock absorption role in the upper structure; the rubber beams can limit overlarge slippage in the earthquake and has a limit resetting function; and the building of the invention has simple construction, convenience in drawing materials, economical efficiency and effectiveness and environment-friendly drawn materials, and facilitates building construction in towns.

Owner:CHONGQING UNIV

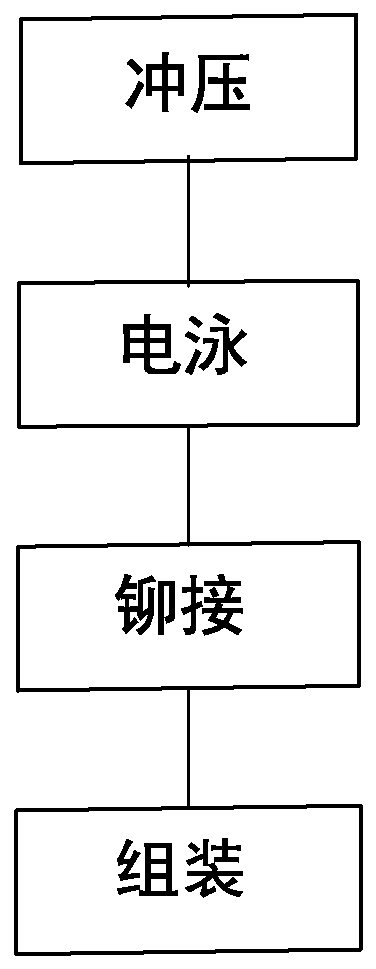

Production process of stretching device

The invention discloses a production process of a stretching device. The production process of the stretching device comprises the following steps of punching: putting purchased coiled materials intoa punching machine to be punched to enable plates to deform to the required workpiece shape; electrophoresis: carrying out electrophoresis on parts one by one, enabling each connecting piece of the stretching device to have a wear-resistant characteristic, and the precision of each single connecting piece to be high, and therefore enabling the integral precision of the stretching device to be highand the running effect to be good; riveting: riveting the connecting pieces into components on riveting equipment; and assembling: assembling the riveted parts, and finally forming the stretching device. Workpieces formed in the punching process include driving parts and driven parts, and the workpieces obtained through the process have higher wear resistance in actual use.

Owner:嘉兴市川扬智能家居制造有限公司

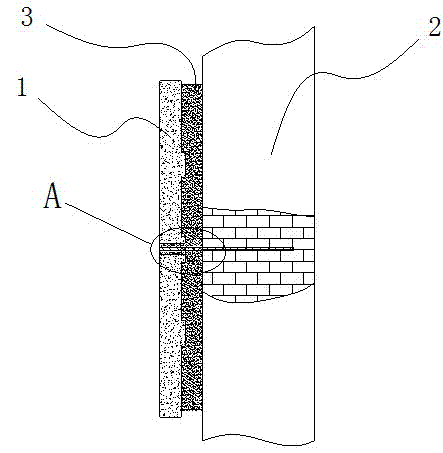

Heat-insulating wall

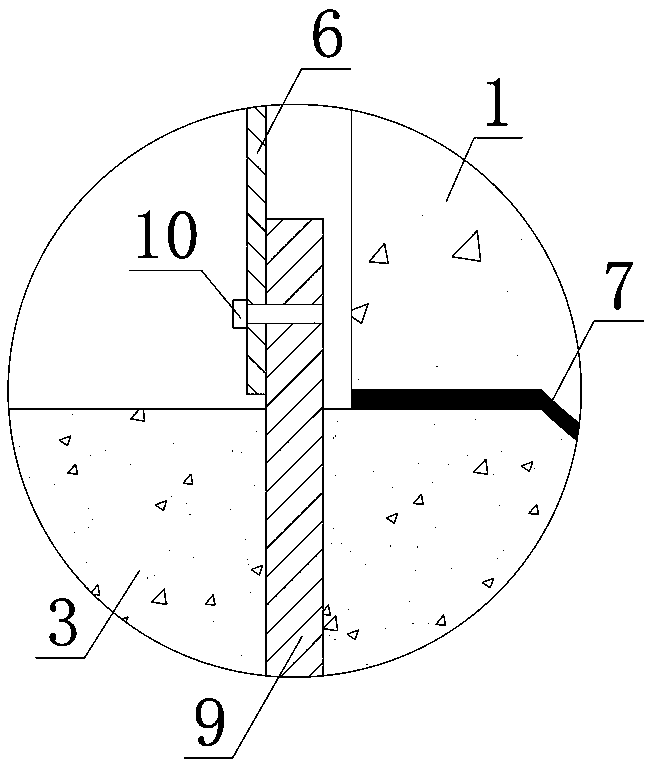

InactiveCN103206031ALimit slipSolve the problem of easy falling off from the wallWallsHeat proofingStructural engineering

The invention relates to a heat-insulating wall which comprises a foundation wall and a heat-insulating plate adhered on the outer side of the foundation wall. Interface mortar is arranged between the foundation wall and the heat-insulating plate, an outrigger is arranged on the side face, used for being mounted on the foundation wall, of the heat-insulating plate, one end of the outrigger is connected on the heat-insulating plate while the other end of the same is buried in the foundation wall, and the part between the two ends is poured in a bonding layer of the interface mortar. By simply arranging the outrigger and performing anti-oxidation protection to the same through a plaster layer, problems, that people want to solve all the time, including that the heat-insulating plate is prone to shedding from the wall and the heat-insulating wall has to be overhauled within 20 years are solved, so that the heat-insulating wall has substantive characteristics and advancement.

Owner:天利建筑工程有限公司

Production process of crease-resistant and wear-resistant suit fabric

PendingCN113308900AHigh breaking strengthAvoid breakingLamination ancillary operationsLaminationFiberPolymer science

The invention discloses a production process of a crease-resistant and wear-resistant suit fabric. The process comprises the following steps of dyeing and fixing a first textile layer, swelling the fixed first textile layer, sequentially padding in a penetrant, a wear-resistant agent solution and a crease-resistant agent solution, performing water washing and drying, placing the first textile layer and a second textile layer on a setting machine for setting treatment, and compounding the first textile layer and the second textile layer by using a hot melt adhesive so as to obtain the crease-resistant and wear-resistant suit fabric. According to the crease-resistant and wear-resistant suit fabric, by adding the wear-resistant agent solution, the breaking strength of the fabric fiber structure is effectively improved, the fabric is soft and has texture, the fabric fiber structure is compact and three-dimensional due to the crease-resistant agent solution added in the swelling state of the fabric, the slippage of molecules and molecular chains is limited, original hydrogen bond breaking can be effectively prevented, and a good crease-resistant effect is achieved.

Owner:安徽弋尚纺织科技有限公司

Dynamic filtering pressing dehydrator

ActiveCN102350108BExtended service lifeLimit compressionSludge treatment by de-watering/drying/thickeningFiltration separationElastomerEngineering

Owner:浙江金鸟压滤机有限公司

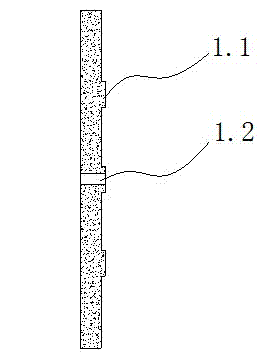

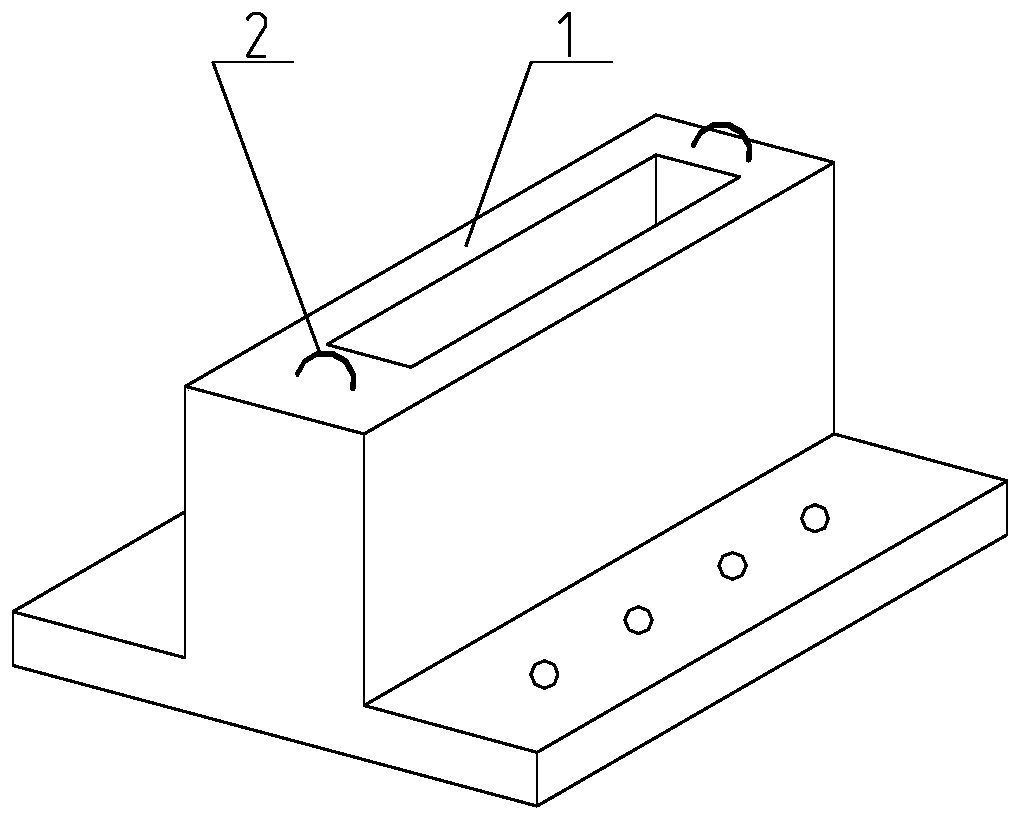

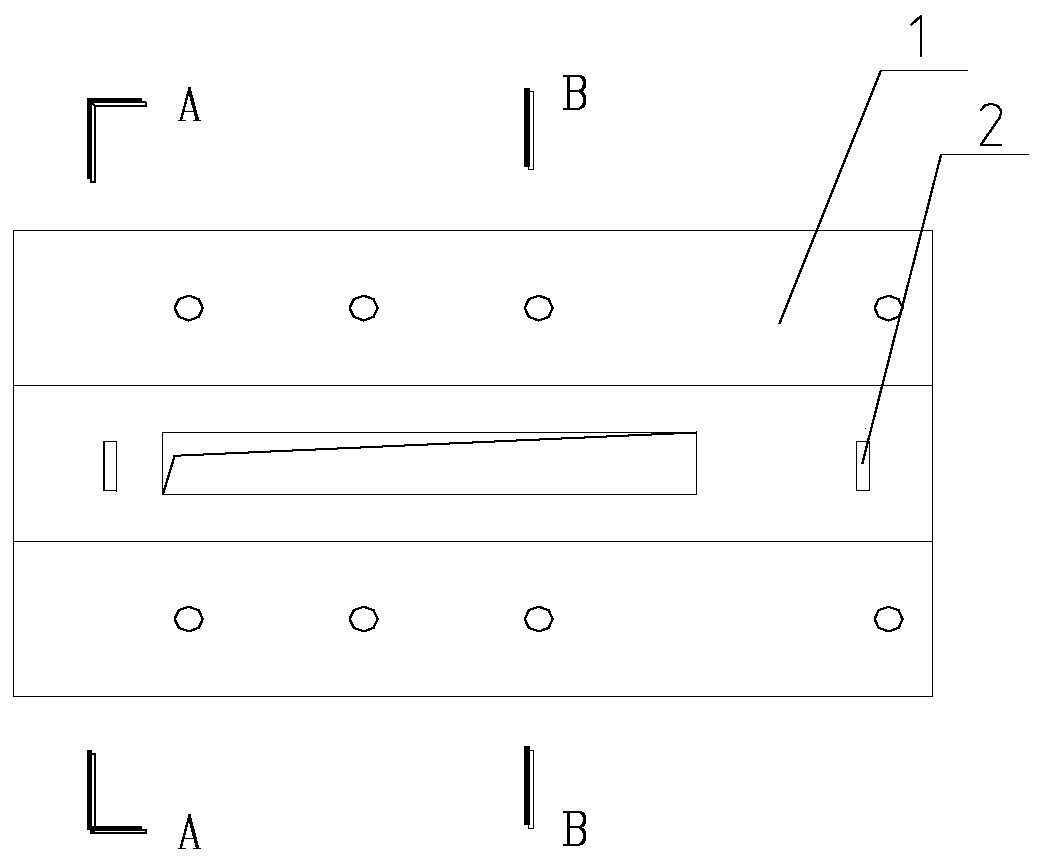

Assembly method for embedded connection between ground beam and shear wall

InactiveCN111042616ALimit slipLimit overturningWallsFoundation engineeringClassical mechanicsEngineering

The invention discloses an assembly method for embedded connection between a ground beam and a shear wall. The method mainly comprises the steps of designing drawings of the ground beam with a grooveand the shear wall, manufacturing molds conforming to the ground beam with the groove and the shear wall, manufacturing the ground beam with the groove and the shear wall, detaching the molds after concrete setting, then maintaining the ground beam with the groove and the shear wall for 28 days under standard conditions, and carrying out embedded assembly connection. The wall manufactured throughthe method has high bearing capacity and anti-seismic property, sliding and overturning of the wall under the load effect can be effectively limited, and good integrity of the wall and the ground beamstructure is kept.

Owner:DALIAN NATIONALITIES UNIVERSITY

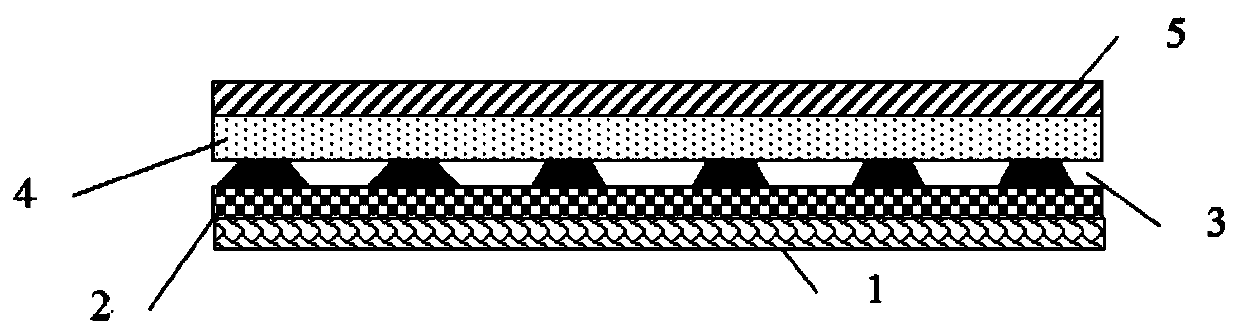

Pavement structure using super-viscous fiber wearing layer

The invention discloses a pavement structure using a super-viscous fiber wearing layer. The pavement structure using the super-viscous fiber wearing layer comprises a base layer with the compaction strength, a high-permeability emulsified asphalt oil-penetrating layer, a structural reinforcement layer, a modified emulsified asphalt viscous oil layer and the super-viscous fiber wearing layer containing roving type glass fibers from bottom to top. The structural reinforcement layer comprises reinforcement ribs distributed in parallel, the reinforcement ribs are fixed through a fixing groove in the bottom or at least two transverse bars transversely penetrating in the vertical direction, the reinforcement ribs are filled with aggregates, and the reinforcement ribs are hollow circular tube type reinforcement ribs or sleeper type reinforcement ribs with trapezoidal sections. According to the pavement structure using the super-viscous fiber wearing layer, asphalt pavements with poor structural strength and being prone to sinking can be laid and repaired with super-viscous fiber wearing layer materials, and the structure is reinforced through the thickness of a reinforcement rib adjustingstructure reinforcement layer, and meanwhile, the pavement structure can be applied to repair and complement of defects with larger depth.

Owner:山西省交通新技术发展有限公司

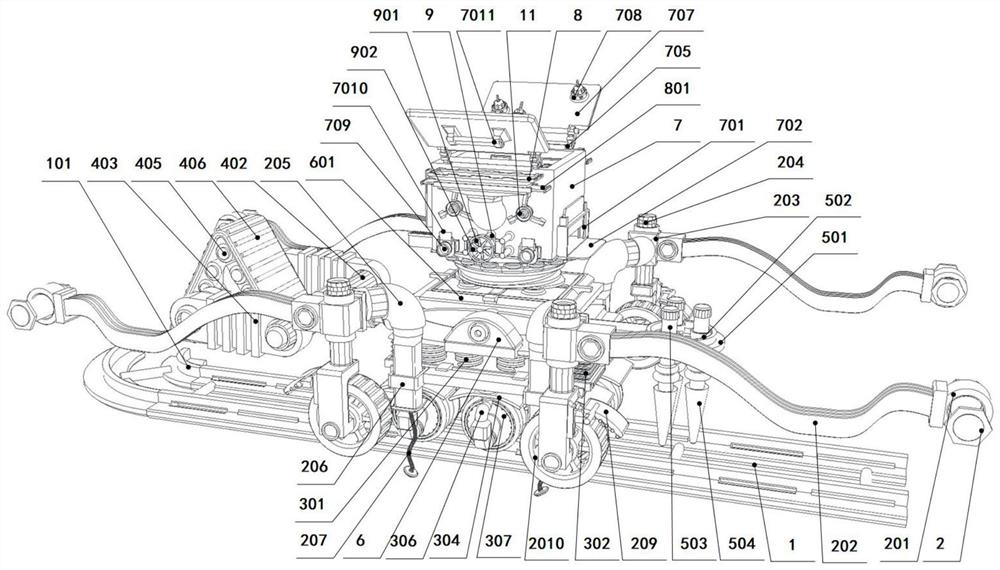

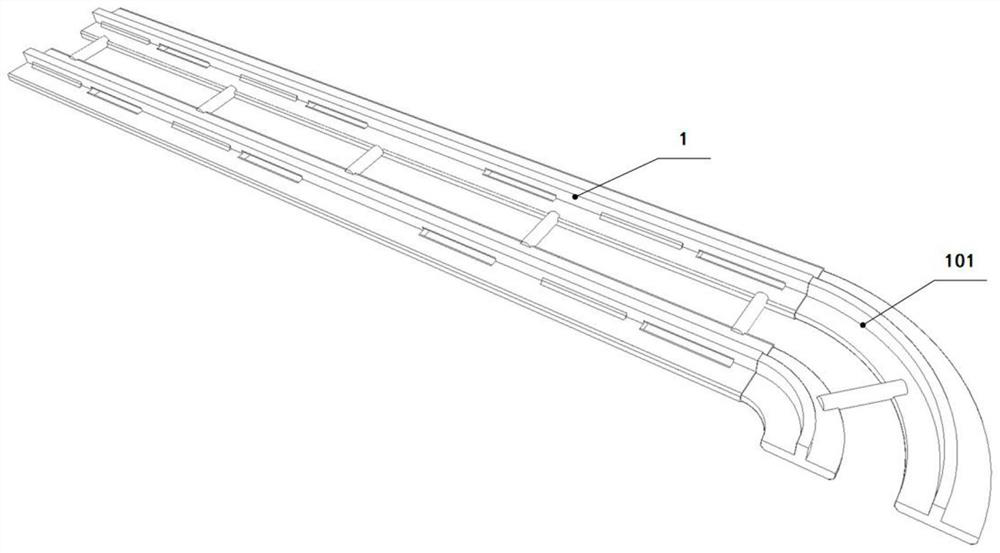

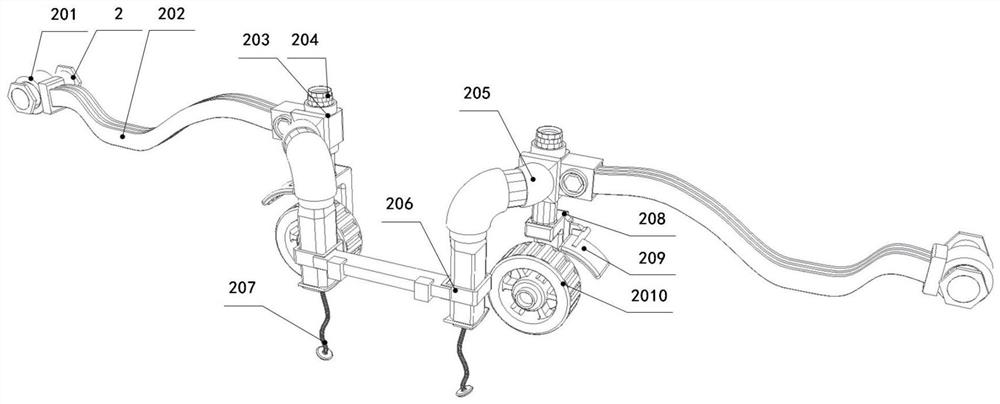

An explosion-proof transport vehicle

ActiveCN111908051BImprovement of self-management abilityPlay the role of heat insulation and coolingFire rescueMechanical conveyorsWater storageThermodynamics

The invention discloses an explosion-proof transport vehicle, which includes straight rails, curved rails, an independent moving system, a rail moving system, a spanning system, a fixing system, a base system, and a loading system; The tool can not only carry out high-speed transfer operations along the established path, but also carry out free-moving transportation operations in complex terrains; through the installation of metal conduits in the independent moving system, even if the carrier encounters strong external factors such as lightning strikes in the work site At the same time, by storing water in the box of the loading system and setting a flip door above the box, it can play a role in heat insulation and cooling, so that the vehicle will not have accidents due to a sharp rise in temperature after a long period of exposure Accident; by setting the wave plate and the baffle rod in the loading system, the slippage of coal particles is limited to the greatest extent, the filling rate between coal materials can be improved, and the possibility of friction sparks caused by materials can also be reduced.

Owner:山东中煤工矿物资集团有限公司

An adaptive sandy bionic mechanical foot

Owner:JILIN UNIV

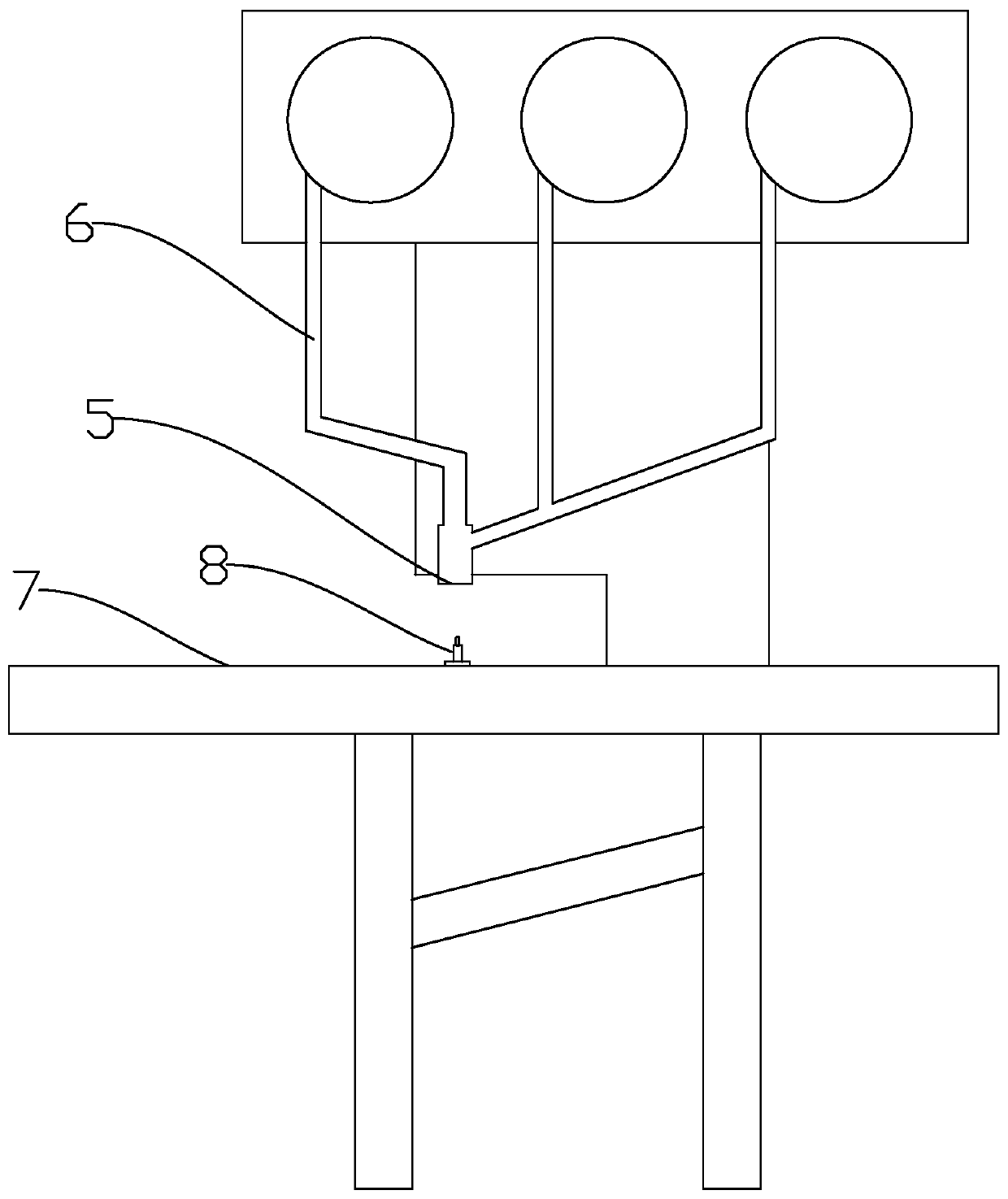

Gang drilling machine

PendingCN109604672AAvoid manual turning movementLimit slipLarge fixed membersBoring/drilling machinesPipe fittingDrilling machines

The invention discloses a gang drilling machine. The gang drilling machine comprises a rack. A base is arranged on the rack. The base is provided with a gang drilling unit used for drilling pipe fittings. A pipe fitting rotating device allowing the gang drilling unit to drill the pipe fittings is arranged at one side of the gang drilling unit and is used for rotating the pipe fittings needing to be drilled by 360 degrees. The gang drilling unit can slide on the base so as to move close to or away from the pipe fitting rotating device. According to the gang drilling machine, the drilled pipe fittings do not need to b moved manually, the hole drilling numbers of the pipe fittings are adjustable, meanwhile, alignment and correction are precise, no time is wasted, the production cost is lowered, the efficiency is high, the product accuracy is high, the phenomenon that after being machined, the pipe fittings fail to be used normally due to hole position distance deviation is avoided, and the pipe fittings with the different diameters and sizes can be drilled.

Owner:NANTONG BAIHAI MUNICIPAL FACILITIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com