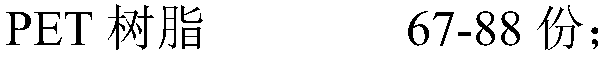

Injection molding grade glass fiber reinforced PET (Polyethylene Terephthalate) micro-foamed composite material and preparation method thereof

A composite material and micro-foaming technology, which is applied in the field of polymers, can solve the problems of cell collapse and low PET melt strength, and achieve the effects of fine cells, excellent mechanical properties, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The specific preparation method of the injection molding grade glass fiber reinforced PET micro-foaming composite material in the present embodiment comprises the following steps:

[0031] (1) First dry the alkali-free E-grade chopped glass fiber precursor at 120°C for 8 hours; weigh 95 parts of dried alkali-free E-grade chopped glass fiber precursor and 5 parts of isocyanate propyltriethoxysilane Add 500mL of xylene, under nitrogen protection, heat up to 70°C and stir for 6 hours at a constant temperature, centrifuge, wash with xylene 4 times, vacuum dry the centrifuged product at 65°C for 36 hours, and finally obtain modified glass fiber;

[0032] (2) 88 parts of PET resin, 2 parts of maleic anhydride grafted ethylene-butene copolymer, 0.5 part of pyromellitic dianhydride, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, zinc stearate Mix 0.5 parts in a high-speed mixer for 10 minutes, put it into the main feed of the co-rotating twin-screw extruder, weigh 1...

Embodiment 2

[0035] The specific preparation method of the injection molding grade glass fiber reinforced PET micro-foaming composite material in the present embodiment comprises the following steps:

[0036] (1) First dry the alkali-free E-grade chopped glass fiber precursor at 130°C for 6 hours, weigh 95 parts of dried alkali-free E-grade chopped glass fiber precursor, and 5 parts of isocyanate propyltriethoxysilane Add 500mL of xylene, under nitrogen protection, heat up to 80°C and stir for 6 hours at a constant temperature, centrifuge, wash with xylene for 4 times, and vacuum-dry the centrifuged product at 65°C for 36 hours to finally obtain modified glass fibers for later use;

[0037] (2) 77 parts of PET resin, 3 parts of glycidyl methacrylate grafted ethylene-butene copolymer, 1 part of pyromellitic dianhydride, 0.2 part of antioxidant 1010, 0.2 part of antioxidant 168, pentaerythritol 1 part of stearate was mixed in a high-speed mixer for 10 minutes, and put into the main feed of t...

Embodiment 3

[0040] The specific preparation method of the injection molding grade glass fiber reinforced PET micro-foaming composite material in the present embodiment comprises the following steps:

[0041] (1) First dry the alkali-free E-grade chopped glass fiber precursor at 150°C for 5 hours, weigh 90 parts of dried alkali-free E-grade chopped glass fiber precursor, and 10 parts of isocyanate propyltriethoxysilane Add 500mL of xylene, under the protection of nitrogen, heat up to 80°C and stir for 8 hours at a constant temperature, centrifuge, wash with xylene for 5 times, and vacuum-dry the centrifuged product at 80°C for 48 hours to finally obtain modified glass fibers for later use;

[0042](2) 67 parts of PET resin, 3 parts of glycidyl methacrylate grafted ethylene-butene copolymer, 2 parts of pyromellitic dianhydride, 0.15 part of antioxidant DLTP, 0.15 part of antioxidant 168, hard 0.75 part of zinc fatty acid, 0.5 part of ultraviolet absorber, 0.5 part of light stabilizer, 1 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com