Heat-insulating wall

A technology for thermal insulation walls and thermal insulation boards, applied in the direction of thermal insulation, walls, building components, etc., can solve the problems of high cost, poor bonding performance and cracking of composite boards and plastering layers, so as to prevent weathering or oxidation and prolong safety The effect of age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

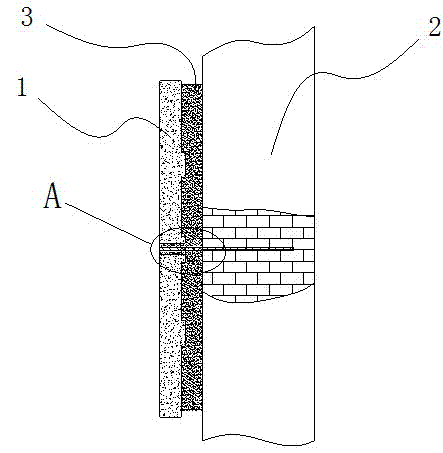

[0020] according to figure 1 , figure 2 and image 3 As shown, the thermal insulation wall in the present invention includes a foundation wall 2 and a thermal insulation board 1 pasted on the outside of the foundation wall 2 .

[0021] Wherein, the foundation wall 2 is formed by stacking bricks through normal construction methods (of course, it can also be formed by integrally pouring cement concrete).

[0022] Among them, the insulation board 1 is a rigid foam plastic board made of polystyrene resin as raw material plus other raw and auxiliary materials and polymers, mixed with heat and injected with a catalyst, and then extruded and formed (of course, it can also be Insulation boards of other materials).

[0023] Between the foundation wall 2 and the insulation board 1 is an interface mortar bonding layer 3 , which can also be used as a board and wall bonding layer to paste the insulation board 1 on the foundation wall 2 . The interface mortar bonding layer 3 is made of...

Embodiment 2

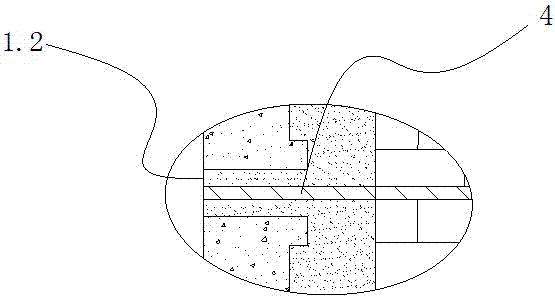

[0026] This embodiment is an improvement on the basis of Embodiment 1. A plurality of through holes 1.2 filled with concrete are opened on the insulation board 1, and one end of the cantilever 4 fixed on the insulation board 1 is plugged into the concrete in the through holes 1.2. Among them, the cantilever beam 4 is fixed in the through hole 1.2 by concrete pouring.

Embodiment 3

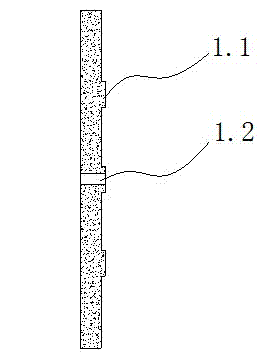

[0028] This embodiment is an improvement based on the second embodiment. On the side of the insulation board 1 for installation to the foundation wall 2, there are densely distributed cylindrical protrusions 1.1. The length of the columnar protrusion 1.1 is smaller than the length of the cantilever 4, and the columnar protrusion 1.1 is also embedded in the interface mortar bonding layer 3.

[0029] It is conceivable that the through hole 1.2 can be opened on the cylindrical protrusion.

[0030] According to the foregoing technical solution, it is obviously conceivable that there is at least one cantilever beam 4, and there is at least one through hole 1.2 corresponding thereto.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com