Polyvinyl fishing net composite material and preparation method thereof

A composite material, polyethylene-based technology, applied in the direction of single-component polyolefin rayon, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of low tensile strength, poor toughness, no wear resistance, etc. Effects of stiffness and nodular strength, high retention of breaking strength, enhanced anti-aging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

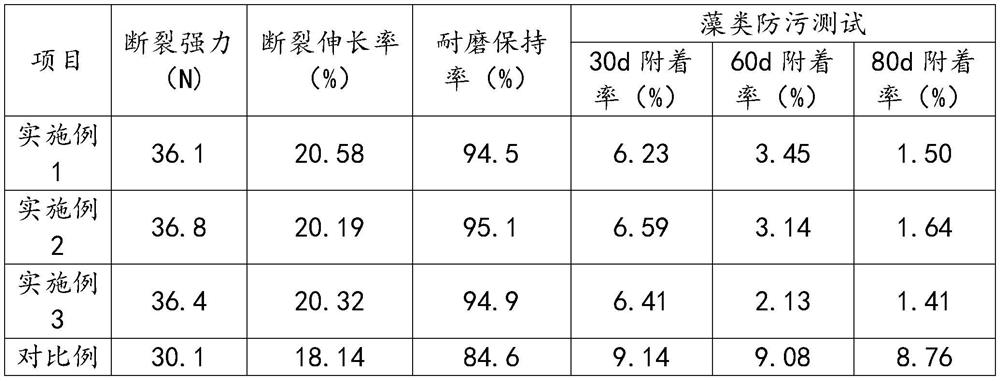

Examples

Embodiment 1

[0028] A polyethylene-based fishing net composite material, comprising the following raw materials in parts by weight: 200 parts of polyamide chips, 20 parts of modified polyethylene fibers, 10 parts of dicumyl peroxide, 5 parts of antifouling fillers, 1 part of compatibilizer and 0.5 part of anti-aging agent;

[0029] The polyethylene-based fishing net composite material is made by the following steps:

[0030] The first step is to add polyamide slices, dicumyl peroxide, compatibilizer and anti-aging agent into the reactor, heat and keep the temperature of the reactor at 260°C, and mix for 20 minutes at a speed of 300r / min to obtain the first mixture , adding modified polyethylene fiber and anti-fouling filler to the first mixture, under the condition of constant speed, continue mixing for 20min to obtain the second mixture;

[0031] The second step is to transfer the second mixture to the twin-screw extruder for extrusion and granulation. During extrusion, four-stage heatin...

Embodiment 2

[0041] A polyethylene-based fishing net composite material, comprising the following raw materials in parts by weight: 250 parts of polyamide chips, 25 parts of modified polyethylene fibers, 12 parts of dicumyl peroxide, 8 parts of antifouling fillers, 2 parts of compatibilizers and 0.8 part of anti-aging agent;

[0042] The polyethylene-based fishing net composite material is made by the following steps:

[0043] The first step is to add polyamide slices, dicumyl peroxide, compatibilizer and anti-aging agent into the reactor, heat and keep the temperature of the reactor at 280°C, and mix for 30 minutes at a speed of 350r / min to obtain the first mixture , adding modified polyethylene fiber and anti-fouling filler to the first mixture, under the condition of constant speed, continue mixing for 20min to obtain the second mixture;

[0044] The second step is to transfer the second mixture to a twin-screw extruder for extrusion and granulation. During extrusion, four-stage heatin...

Embodiment 3

[0054] A polyethylene-based fishing net composite material, comprising the following raw materials in parts by weight: 200-300 parts of polyamide chips, 30 parts of modified polyethylene fibers, 15 parts of dicumyl peroxide, 10 parts of anti-fouling fillers, 3 parts of compatibilizer and 1 part of anti-aging agent;

[0055] The polyethylene-based fishing net composite material is made by the following steps:

[0056] The first step is to add polyamide slices, dicumyl peroxide, compatibilizer and anti-aging agent into the reactor, heat and keep the temperature of the reactor at 290°C, and mix for 40 minutes at a speed of 400r / min to obtain the first mixture , adding modified polyethylene fiber and anti-fouling filler to the first mixture, under the condition of constant speed, continue mixing for 20min to obtain the second mixture;

[0057] The second step is to transfer the second mixture to the twin-screw extruder for extrusion and granulation. During extrusion, four-stage h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com