Production process of stretching device

A stretching device and production process technology, applied in the processing and production field of the stretching device, can solve the problems of sofas and seats that cannot meet people's needs, poor experience in the use process, short service life, etc., and achieve excellent anti-corrosion ability and coating. Good quality and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

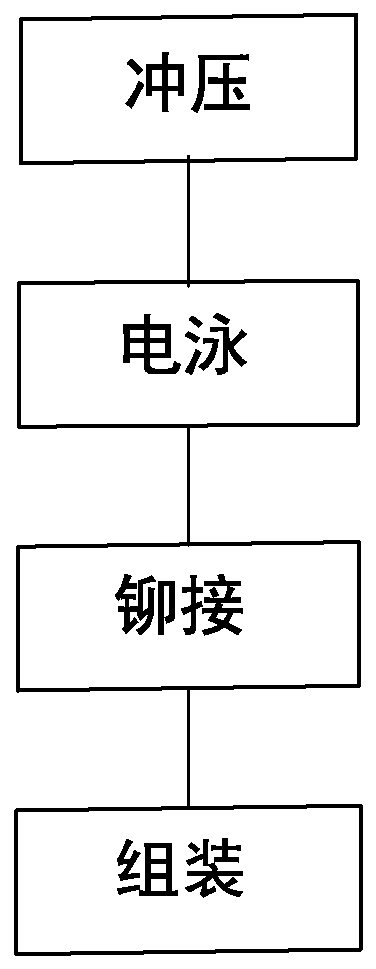

[0035] The invention provides a processing technology for making the stretching device not only anti-corrosion but also smooth working, comprising the following steps:

[0036] Stamping: Put the bought coil material into the stamping machine for stamping, so that the plate is deformed into the required shape of the workpiece;

[0037] Electrophoresis: Electrophoresis is performed on the parts one by one, so that each connecting piece of the stretching device can have a wear-resistant characteristic, and the precision of a single connecting piece is high, making the overall precision of the stretching device high;

[0038] Riveting: riveting the connection parts into parts on the riveting equipment;

[0039] Assembly: Assemble the riveted parts and finally become a stretching device;

[0040] The workpiece formed in the stamping process has active parts and driven parts;

[0041] The above electrophoresis process is: degreasing: the solution is generally a hot alkaline chemic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com