Production process of crease-resistant and wear-resistant suit fabric

A production process and fabric technology, applied in the field of suit fabrics, can solve the problems of easy breakage and damage, poor wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment is a wrinkle-resistant and wear-resistant suit fabric, comprising the following steps:

[0049] S1: Dyeing and fixing the first textile layer, swelling the first textile layer after color fixing, sequentially padding penetrating agent JFC, anti-wear agent solution, anti-wrinkle agent solution, washing and drying;

[0050] Wherein the preparation process of anti-wear agent solution is as follows:

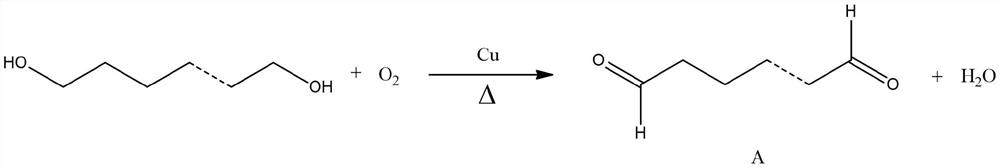

[0051] S21: Put polyethylene glycol and copper sheet into the three-necked flask and seal it, use a vacuum pump to extract the air in the three-necked flask, inject oxygen into the three-necked flask, and move the three-necked flask to a constant temperature water bath, heat to 60°C and stir for 1 , to obtain intermediate A;

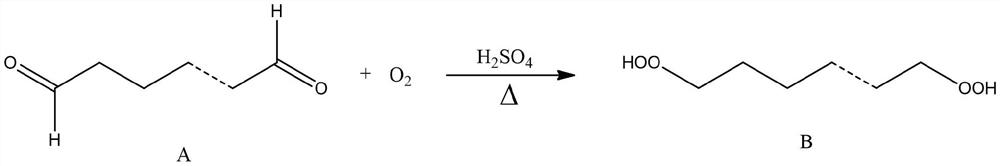

[0052] S22: add dilute sulfuric acid to intermediate A and continue stirring for 2 to obtain intermediate B;

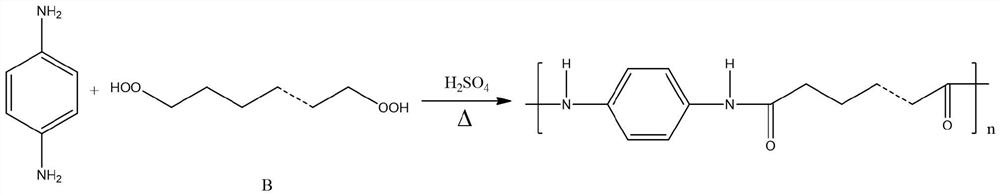

[0053] S23: Add p-phenylenediamine to intermediate B, use diethanolamine as a neutralizing agent, react 5 and stir to obtain ...

Embodiment 2

[0062] This embodiment is a wrinkle-resistant and wear-resistant suit fabric, comprising the following steps:

[0063] S1: The first textile layer is dyed and color-fixed, and the first textile layer after color-fixing is swollen and sequentially padded with penetrant JFC, anti-wear agent solution, and anti-wrinkle agent solution, and then washed and dried;

[0064] Wherein the preparation process of anti-wear agent solution is as follows:

[0065] S21: Put polyethylene glycol and copper sheet into the three-necked flask and seal it, use a vacuum pump to extract the air in the three-necked flask, inject oxygen into the three-necked flask, and move the three-necked flask to a constant temperature water bath, heat to 70°C and stir for 2 hours , to obtain intermediate A;

[0066] S22: Add dilute sulfuric acid to intermediate A and continue stirring for 3 hours to obtain intermediate B;

[0067] S23: Add p-phenylenediamine to the intermediate B, use diethanolamine as a neutraliz...

Embodiment 3

[0076] This embodiment is a wrinkle-resistant and wear-resistant suit fabric, comprising the following steps:

[0077] S1: Dyeing and fixing the first textile layer, swelling the first textile layer after color fixing, sequentially padding penetrating agent JFC, anti-wear agent solution, anti-wrinkle agent solution, washing and drying;

[0078] Wherein the preparation process of anti-wear agent solution is as follows:

[0079] S21: Put polyethylene glycol and copper sheet into the three-necked flask and seal it, use a vacuum pump to extract the air in the three-necked flask, inject oxygen into the three-necked flask, and move the three-necked flask to a constant temperature water bath, heat to 65°C and stir for 1h , to obtain intermediate A;

[0080] S22: Add dilute sulfuric acid to intermediate A and continue stirring for 2 hours to obtain intermediate B;

[0081] S23: Add p-phenylenediamine to the intermediate B, use diethanolamine as a neutralizing agent, react for 5 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wrinkle recovery angle | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com