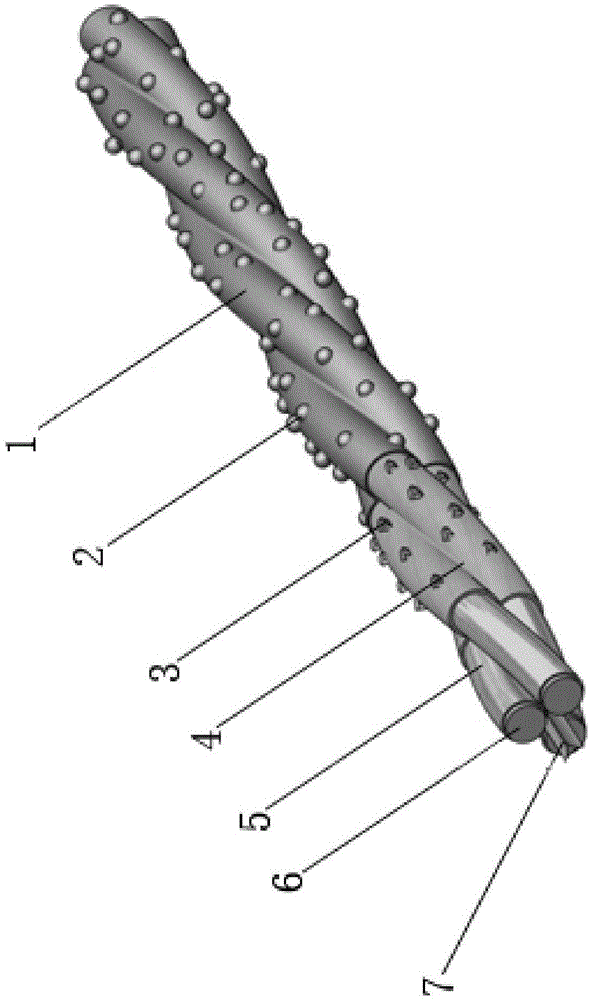

Novel composite metal fixed abrasive diamond rope and production process thereof

A composite metal and fixed abrasive technology, which can be used in manufacturing tools, stone processing equipment, fine working devices, etc., and can solve the problems of low cutting efficiency and poor chip removal ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0038] (1) Core rope composite: The core rope is prepared by twisting three strands of φ0.080mm copper-plated steel wire and one strand of φ0.010mm soft polymer filling strip. The material of the soft polymer filling strip is ethylene-ethyl acrylate copolymer Material, its ethyl acrylate content is 20-30%.

[0039] (2) Surface pretreatment: the core rope is unwound by the pay-off wheel, and is treated with alkaline degreasing agent solution at 60±5°C, washing water, 10% sulfuric acid solution at 40±5°C and washing water to obtain a core with a clean surface. rope.

[0040] (3) Adhesive nickel layer deposition: The core rope that has been cleaned on the surface is deposited on the surface with a layer of nickel layer medium with high adhesion and fine grains through the flash nickel process. By adjusting the speed of the metal rope, solution formula, current, and pH value , temperature, stirring and other parameters to adjust the grain size and film thickness distribution of t...

Embodiment approach 2

[0045] The difference from Example 1 is that the core rope is a core rope made by twisting three strands of φ0.130mm copper-plated steel wire and one strand of φ0.017mm soft polymer filling strip, and the material of the soft polymer filling strip is Ethylene-propylene-1-butene copolymer, the specification of the diamond particles is 30 / 40. Other steps are all the same as in Example 1, and the specification of the finished product diamond rope is 0.340±0.015mm.

Embodiment approach 3

[0047]The difference from Example 1 is that the core rope is a core rope made by twisting three strands of φ0.160mm copper-plated steel wire and one strand of φ0.020mm soft polymer filling strip, and the material of the soft polymer filling strip is Ethylene-propylene-1-butene copolymer, the specification of the diamond particles is 40 / 50. Other steps are all the same as in Example 1, and the specification of the finished product diamond rope is 0.420±0.020mm.

[0048] The material of the polymer fiber silk in the present invention can be polyethylene, polyvinyl acetate, polyethyl acrylate, polypropylene, polyamide, linear saturated polyester, polyurethane and other thermoplastic polymers, and can also be the above-mentioned polymers The copolymer has a softening point between 50-150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com