Middle cam of computerized flat knitting machine

A computerized flat knitting machine and triangle technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of insufficient production efficiency, high manufacturing cost and difficulty in installation, and no protective design, etc., to achieve smooth sliding effect and smooth operation The effect of high speed and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

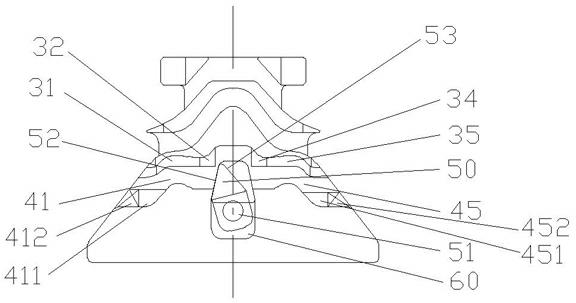

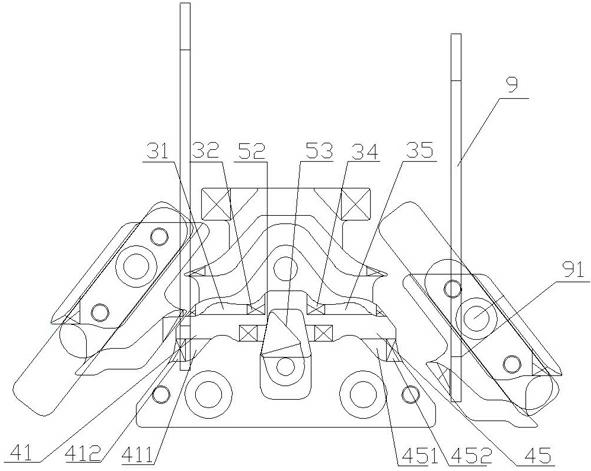

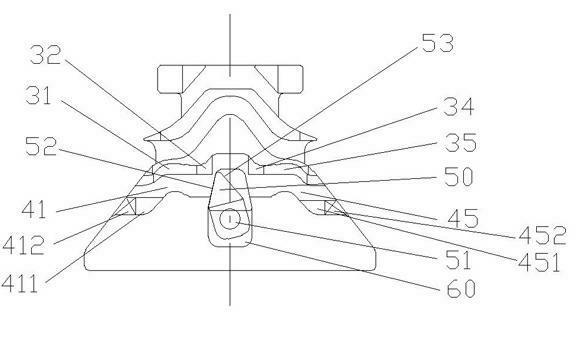

[0022] Such as figure 1 As shown, the Zhongshan triangle of a computerized flat knitting machine of the present invention is fixedly installed on the triangle bottom plate, and includes a left-right symmetrical body 100. The body 100 can be arranged integrally or separately.

[0023] Generally, in the Zhongshan triangle, in addition to the needle track, it also includes transfer, loop and tuck tracks. This is the prior art and will not be repeated here. The stitching track in the Zhongshan triangle is the track for completing the stitching knitting action, as follows:

[0024] The third track 30 and the fourth track 40 are both in a figure-eight shape and run through the body left and right, and are tuck and needle tracks. A middle groove 43 is formed in the middle of the two tracks, and a limit groove 60 is provided directly below the middle groove 43, and a swing triangle 50 is arranged in the limit groove 60, and the swing triangle 50 is positioned by a center hole 51, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com