Hollow porous absorbable suture line and preparation method

A technology of porous parts and sutures, applied in textiles and papermaking, trocars, knitted fabrics, etc., can solve the problems of increasing the complexity of the preparation process, requiring further verification, damage to the tubular sutures, etc., and is conducive to tissue ingrowth. With the effect of regeneration, reducing cutting, accelerating repair and healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

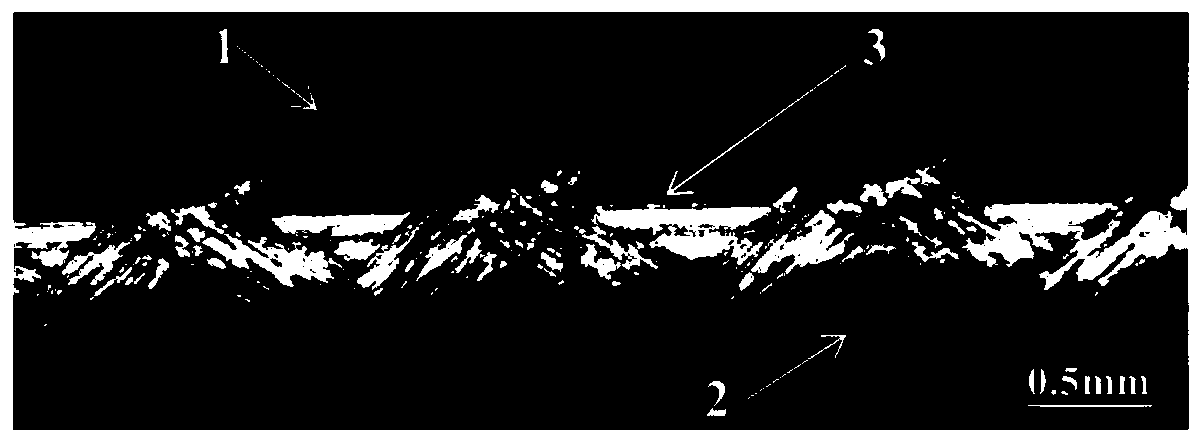

[0026] Such as figure 1 As shown, this embodiment provides a hollow porous partially absorbable suture, the preparation method of which includes: weaving non-absorbable yarn 1 and absorbable shaft yarn 2 through two-dimensional and triaxial weaving process outside the inner liner tube 3 The surface is preformed to obtain a surface porous suture, and the obtained surface porous suture is heat-treated together with the inner liner 3, so that the part of the absorbable shaft yarn 2 is melted, and the weaving points of the non-absorbable woven yarn 1 are bonded, and then removed Liner tube 3, resulting in a hollow porous part absorbable suture.

[0027] The specific preparation steps of the hollow porous absorbable orthopedic suture are as follows:

[0028] Step 1): Select FDA-approved polypropylene monofilament ( Ethicon) is a non-absorbable braided yarn material with a diameter of 0.15mm; select polydioxanone monofilament (prepared by melt spinning) as the core yarn material ...

Embodiment 2

[0034] Such as figure 1 As shown, this embodiment provides a hollow porous partially absorbable suture, the preparation method of which includes: weaving non-absorbable yarn 1 and absorbable shaft yarn 2 through two-dimensional and triaxial weaving process outside the inner liner tube 3 The surface is preformed to obtain a surface porous suture, and the obtained surface porous suture is heat-treated together with the inner liner 3, so that the part of the absorbable shaft yarn 2 is melted, and the weaving points of the non-absorbable woven yarn 1 are bonded, and then removed Liner tube 3, resulting in a hollow porous part absorbable suture.

[0035]The specific preparation steps of the hollow porous absorbable orthopedic suture are as follows:

[0036] Step 1): Select FDA-approved polypropylene monofilament ( Ethicon) is a non-absorbable braided yarn material with a diameter of 0.15mm; select polydioxanone monofilament (prepared by melt spinning) as the core yarn material o...

Embodiment 3

[0042] Such as figure 1 As shown, this embodiment provides a hollow porous partially absorbable suture, the preparation method of which includes: weaving non-absorbable yarn 1 and absorbable shaft yarn 2 through two-dimensional and triaxial weaving process outside the inner liner tube 3 The surface is preformed to obtain a surface porous suture, and the obtained surface porous suture is heat-treated together with the inner liner 3, so that the part of the absorbable shaft yarn 2 is melted, and the weaving points of the non-absorbable woven yarn 1 are bonded, and then removed Liner tube 3, resulting in a hollow porous part absorbable suture.

[0043] The specific preparation steps of the hollow porous absorbable orthopedic suture are as follows:

[0044] Step 1): Select FDA-approved polypropylene monofilament ( Ethicon) is a non-absorbable woven yarn material with a diameter of 0.15 mm; poly(4-hydroxybutyrate) monofilament ( Tepha) is the core yarn material of the absorbab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com