Structure-enhanced hydrotalcite-immobilized composite fiber membrane and preparation method and application thereof

A composite fiber membrane and hydrotalcite technology, which is applied in the field of membrane materials, can solve the problems of loss, difficulty in recycling, and reuse, and achieve the effects of enhanced wind pressure resistance, improved electrostatic adsorption effect, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of nickel-aluminum hydrotalcite is the same as above, the only difference is that 2.3264g Ni (NO 3 ) 2 ·6H 2 O replaces Mg(NO 3 ) 2 ·6H 2 O.

[0060] Polyacrylonitrile (PAN) was purchased from J&K Chemical, MW=150000;

[0061] Polyvinylidene fluoride (PVDF) was purchased from Sigma-Aldrich, MW=534000;

[0062] Polycaprolactone (PCL) was purchased from J&K Chemical, MW=10000;

[0063] Nylon-6, CAS No. 25038-54-4;

[0064] Polylactic acid, CAS No. 26100-51-6;

[0065] Magnesium nitrate, aluminum nitrate, and urea were purchased from Xilong Chemical Co., Ltd., all of analytical grade.

Embodiment 1

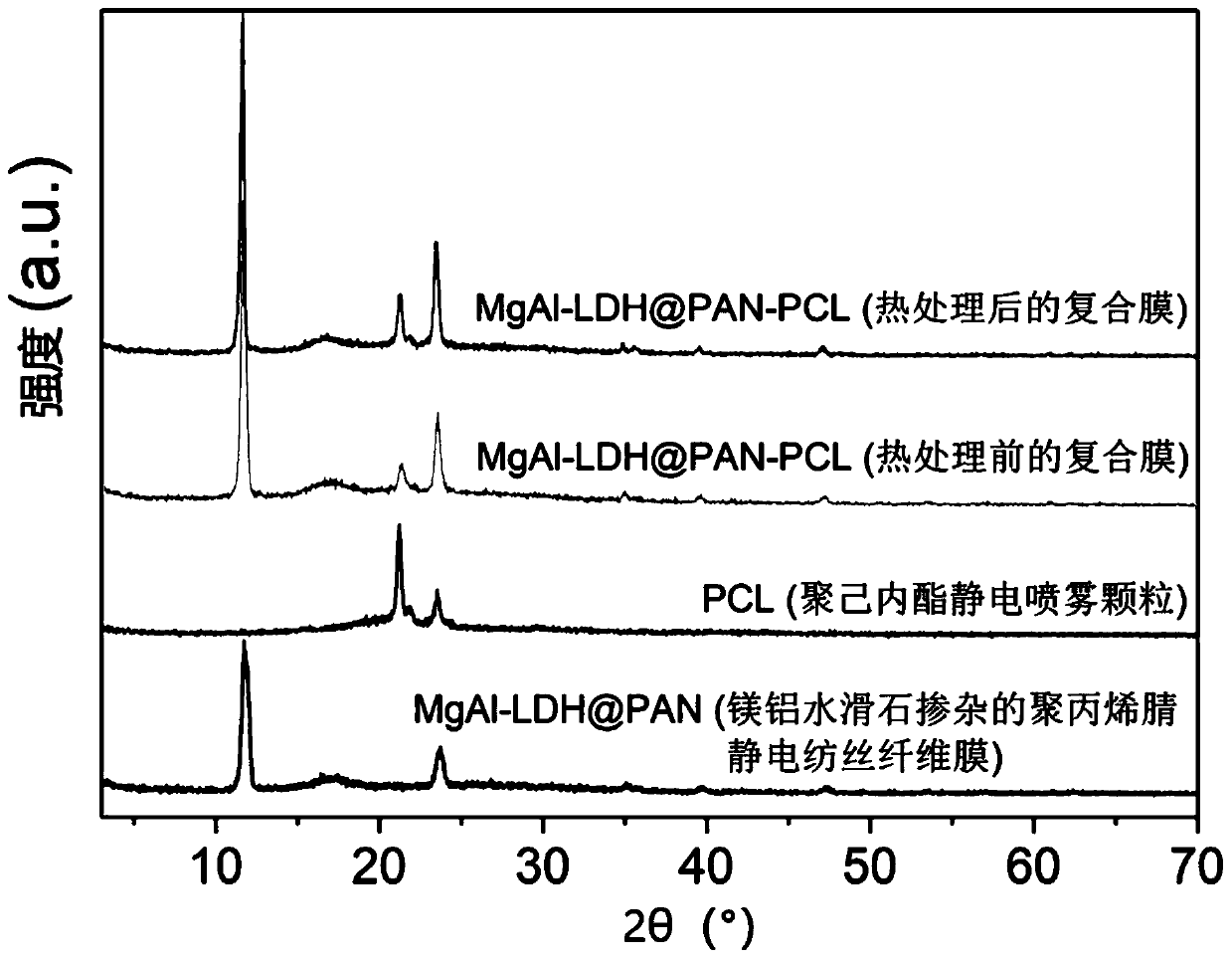

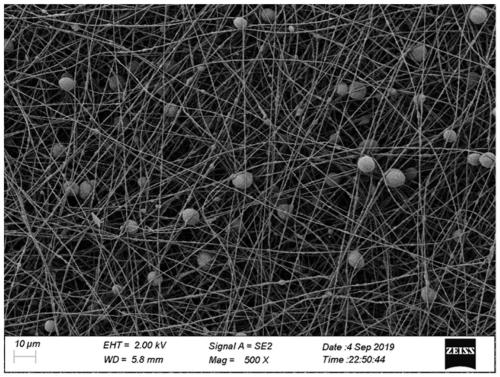

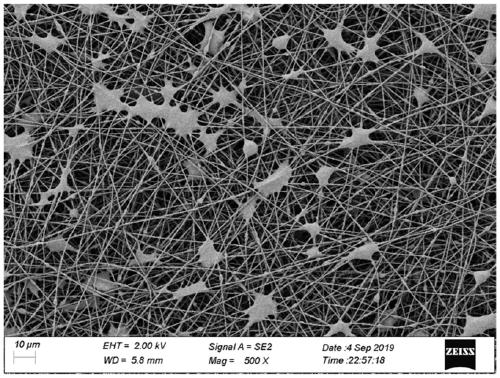

[0067] A preparation method of a structure-reinforced hydrotalcite-supported composite fiber membrane, comprising the following steps:

[0068] (1) Measure 10 mL of N,N-dimethylformamide, add 0.3 g of magnesium-aluminum hydrotalcite to it, and disperse it by ultrasonic, then add 1 g of polyacrylonitrile to the solution, and stir to fully dissolve the polyacrylonitrile. to obtain an electrospinning solution;

[0069] (2) 9 mL of chloroform and 1 mL of N,N-dimethylformamide were weighed, 0.60 g of polycaprolactone was added thereto, and stirred to completely dissolve to obtain an electrostatic spray solution.

[0070] (3) Transfer the electrospinning solution to the syringe, set the spinning needle on the side of the drum receiver, set the electric field voltage between the spinning needle and the drum receiver to 17kV, set the distance to 18cm, and set the spinning flow to 1mL / h;

[0071] Transfer the electrostatic spray solution to the syringe, set the spray needle on the t...

Embodiment 2

[0076] A preparation method of a structure-reinforced hydrotalcite-supported composite fiber membrane, comprising the following steps:

[0077] (1) Measure 7mL of N,N-dimethylformamide and 3mL of acetone, add 0.3g of nickel-aluminum hydrotalcite to it, and disperse it by ultrasonic, then add 1.5g of polyvinylidene fluoride to the solution, stir to make polyvinylidene fluoride The vinylidene fluoride is fully dissolved to obtain the electrospinning solution;

[0078] (2) 9 mL of chloroform and 1 mL of N,N-dimethylformamide were weighed, 0.60 g of polycaprolactone was added thereto, and stirred to completely dissolve to obtain an electrostatic spray solution.

[0079] (3) Transfer the spinning solution into the syringe, set the spinning needle on the side of the drum receiver, set the electric field voltage between the spinning needle and the drum receiver to be 17kV, the distance to be 18cm, and the spinning flow to be 1mL / h;

[0080] Transfer the spray solution into the syr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com