Heat and cold resistant flexible cable

A cold-resistant and flexible technology, used in insulated cables, cables, circuits, etc., can solve the problems of low temperature resistance, extremely high requirements, plastic aging, etc., to achieve enhanced low temperature resistance, good low temperature resistance, and improved heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

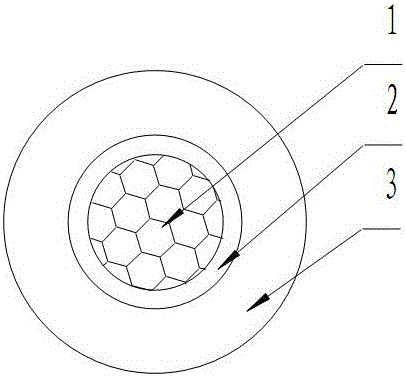

[0028] refer to figure 1 , is a heat-resistant and cold-resistant flexible single-core cable of the present invention, including a conductor 1 , an insulating layer 3 wrapped around the conductor 1 , and a heat-insulating layer 2 arranged between the conductor 1 and the insulating layer 3 .

[0029] When producing the heat-resistant and cold-resistant flexible single-core cable, firstly, conductive metal wires such as multi-strand nickel-copper alloy wires or pure nickel metal wires are bundled and twisted to make conductor 1, and then wrapped with polyimide paper tape A thermal insulation layer 2 of composite structure is formed on the outer surface of the conductor 1, and then a layer of F46 plastic tape or polyurethane tape is wrapped on the outer surface of the thermal insulation layer 2, and then a layer of cylinder net is woven by a circular loom with silicone wire. , and then extrude a layer of silica gel to make the insulating layer 3 of the composite structure.

[00...

Embodiment 2

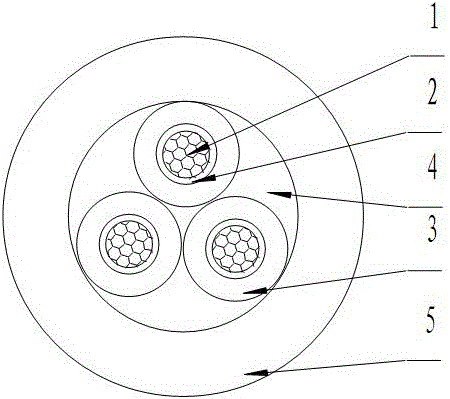

[0033] see figure 2 , is a heat-resistant and cold-resistant flexible multi-core cable of the present invention, comprising three cable cores and a sheath 5 covering the periphery of the three cable cores. Object 4, the cable core adopts the heat-resistant and cold-resistant flexible single-core cable of Embodiment 1, and the insulating layer 3 used for the heat-resistant and cold-resistant flexible single-core cable in this embodiment can be different from the insulating layer 3 in Embodiment 1. The insulating layer 3 can be wrapped with F46 plastic tape or polyurethane tape for one layer, then braided with a layer of cylinder net with silica gel wire, and then coated with a layer of liquid silica gel to obtain a composite insulating layer.

[0034] When producing the heat-resistant and cold-resistant flexible multi-core cable, firstly, the three cable cores are stranded, and then soft silica gel is used as a filler 4 to fill the gap between the cable cores by extrusion mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com